Ceramic circuit board and module using same

A technology for circuit substrates and ceramic substrates, which is applied to the improvement of circuit substrate materials, circuits, and metal adhesion of insulating substrates, etc., can solve the problems such as the inability to meet the heat resistance cycle characteristics, the decrease in the continuity of the solder layer, and the increase in Vickers hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

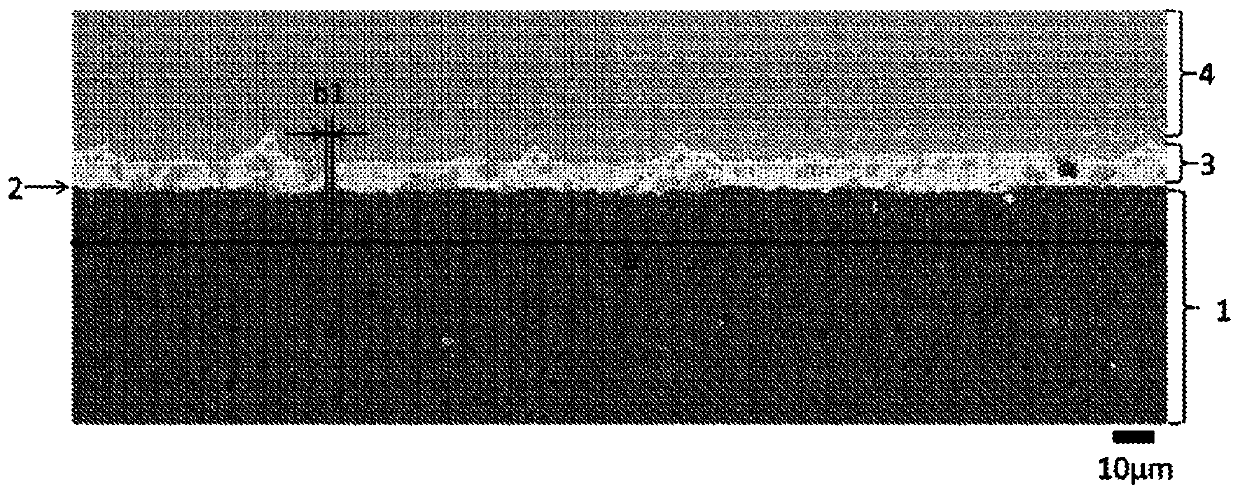

[0056] On a silicon nitride substrate with a thickness of 0.32 mm, 90 parts by mass of Ag powder (manufactured by Fukuda Metal Foil Powder Industry Co., Ltd.: Ag-HWQ2.5 μm) and Cu powder (manufactured by Fukuda Metal Foil Powder Industry Co., Ltd.: Cu -10 parts by mass of 10 parts by mass of HWQ) contains 3.5 parts by mass of TiH2 powder (manufactured by OSAKA Titanium technologies Co., Ltd.: TSH-350) and 3.5 parts by mass of Sn powder (manufactured by Fukuda Metal Foil Powder Industry Co., Ltd.: Sn-HPN 3μm) 3 parts by mass of active metal solder, at 1.0×10 -3 An oxygen-free copper plate with a thickness of 0.8 mm was bonded to the circuit surface, and an oxygen-free copper plate with a thickness of 0.8 mm was bonded to the back surface at 800° C. for 30 minutes in a vacuum below Pa.

[0057] On the bonded circuit board, a UV curable resist is printed as a circuit pattern by screen printing, and after UV curing, the shape of the heat dissipation surface is further printed and ...

Embodiment 2~10、 comparative example 1~7

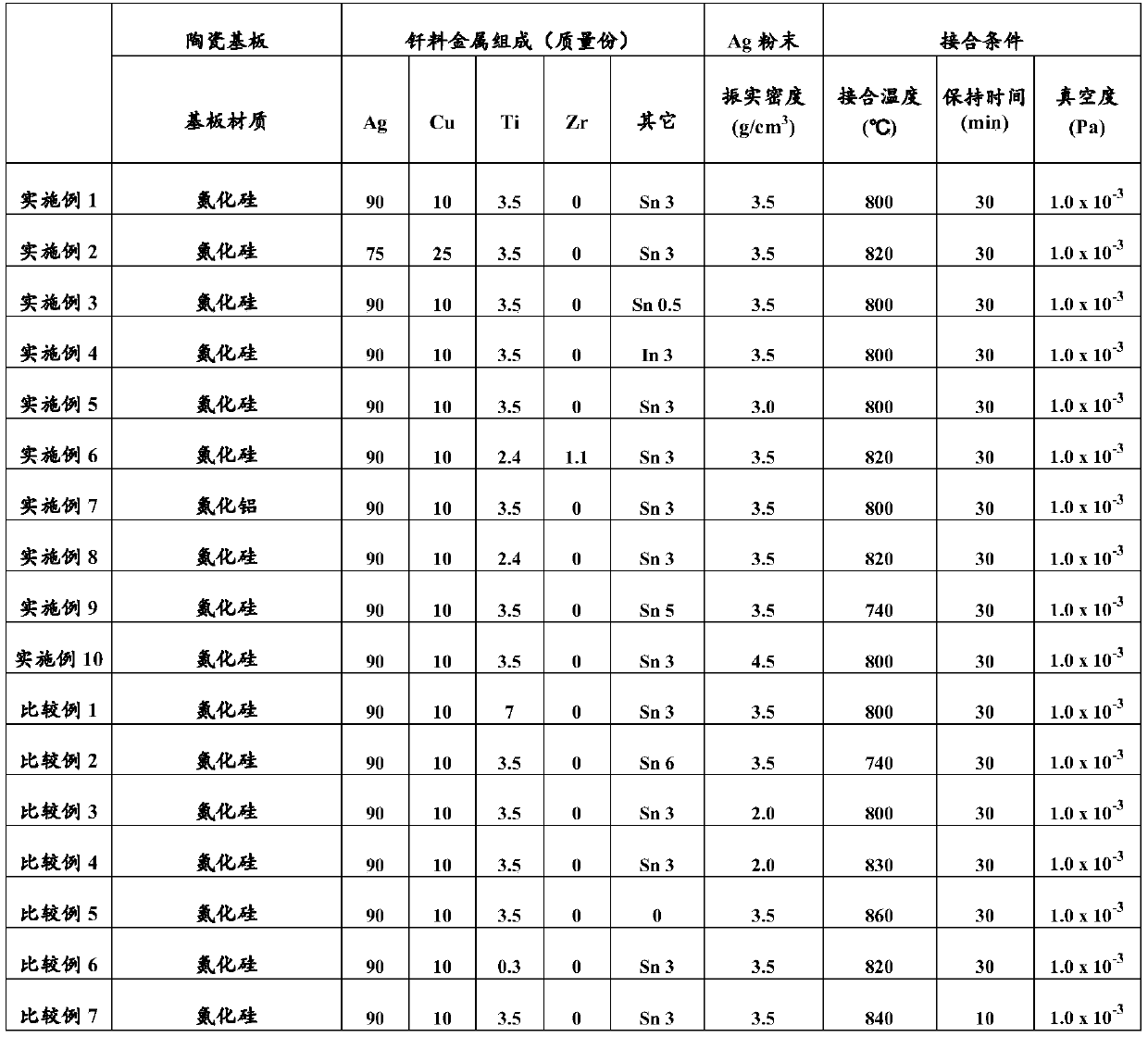

[0066] Except having set the conditions shown in Table 1, it carried out similarly to Example 1. The evaluation results are shown in Table 2.

[0067] 【Table 1】

[0068]

[0069] 【Table 2】

[0070]

[0071]

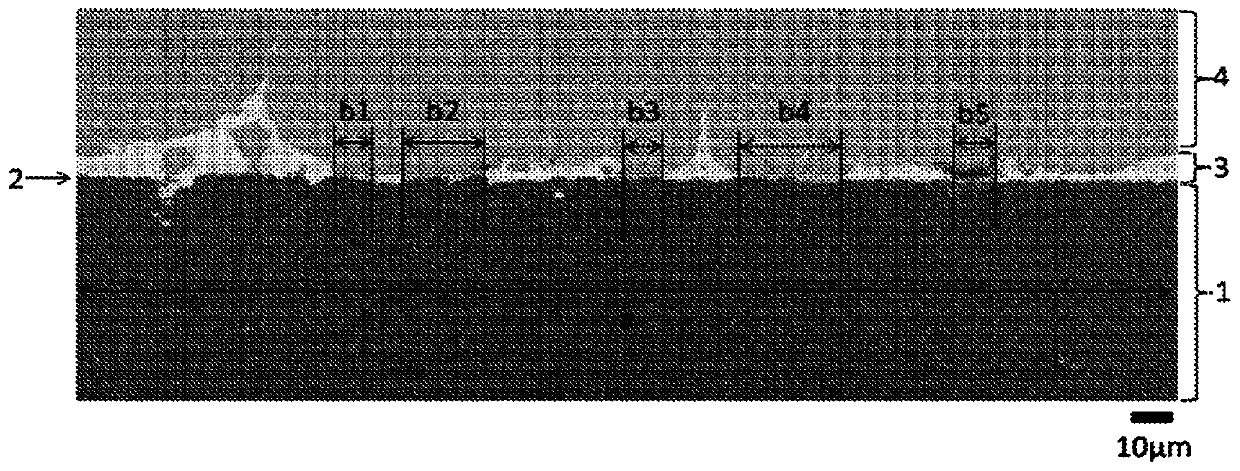

[0072] As shown in Table 2, regarding the use of a tap density of 3 g / cm 3 The above-mentioned Ag powder, the addition amount of In or Sn is 5 parts by mass or less, and the ceramic circuit board produced under the conditions of the bonding temperature is 820 ° C or less. It is confirmed that the Vickers hardness of the solder layer is in the range of 60 to 85 Hv. The occurrence rate of horizontal cracks after the cycle test is less than 1%. Regarding the circuit board produced under the condition that the addition amount of Sn is 3 parts by mass or less and the bonding temperature is 800° C. or less, it was confirmed that the Vickers hardness was in the range of 60 to 75 Hv, and the continuity rate of the solder layer was also 90% or more. The occurrence rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com