Western-style cake and pastry processing machine

A processing machine and pastry technology, applied in the field of food processing equipment, can solve the problems of dissatisfaction with the efficiency and output of hand-made, and achieve the effects of solving large differences in shapes, increasing output, and reducing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

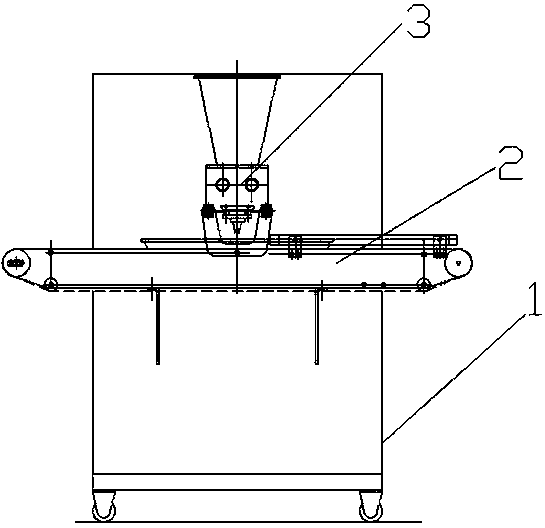

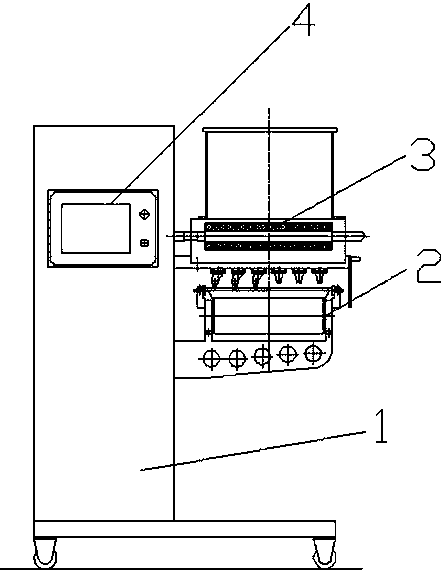

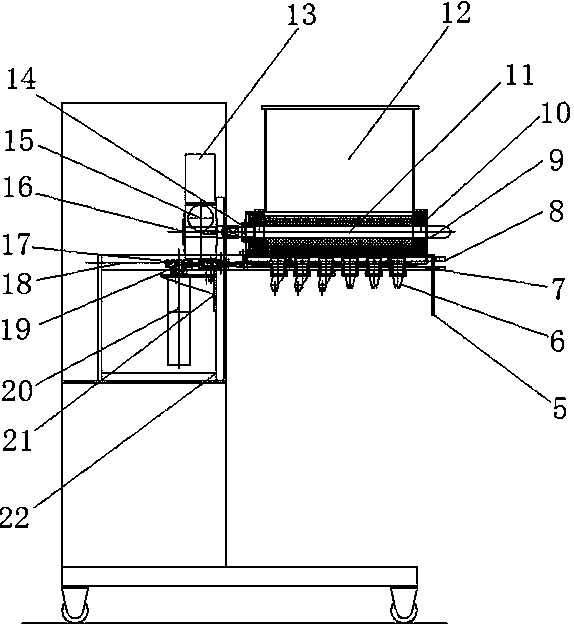

[0023] Such as figure 1 , figure 2 As shown, a pastry processing machine includes a frame 1, on which a pastry forming mechanism 3, a pallet lifting and conveying mechanism 2 and a control unit 4 are installed, and the pastry forming mechanism 3 includes a hopper 12, and the hopper 12 is installed on the hopper Above the seat, the upper seat 10 and the lower seat 9 of the hopper seat cooperate to form a cavity of the hopper seat, and two identical material rollers 11 are installed in the cavity of the hopper seat, and the material roller 11 is driven by the material roller motor 13, and the hopper seat is fixed on the machine. On the support bar 18 connected to the frame 1, a fixed plate 8 is installed under the lower seat of the hopper seat, and a number of twisted gears 7 are installed under the fixed plate 8. A nozzle 6 is installed at the bottom of each twisted gear 7, and a twisted motor 20 is installed. On the twisted flower motor base 21 , the twisted flower motor 20 ...

Embodiment 2

[0028] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, as a further design of Embodiment 1, the pallet lifting and conveying mechanism includes a conveying unit and a lifting unit, wherein the conveying unit is located outside the frame 1 and includes two conveying frame side plates 34 installed on the two conveying frame side plates 34 on the conveyor frame 35, the driving roller 39 installed on the conveyor frame 35, the driven roller 43, the conveyor belt motor seat 40, the conveyor belt motor 41, the turning roller 42, and the drive roller 39 and the driven roller 43 that are sleeved The conveyor belt on the conveyor belt is driven by the conveyor belt motor 41 to complete the intermittent and continuous movement of the tray 28; the lifting unit is located at the bottom of the frame 1 and includes a lifting motor 24, which is installed in the lifting motor seat 23. The lifting motor 24 The output shaft is connected to the ball screw pair 26, ...

Embodiment 3

[0032] As a further optimization of Embodiment 2, the conveying unit also includes baffle mounts 36 installed on both sides of the conveyor frame 35, and a limit baffle 27 is installed on the baffle mount 36, and the limit baffle 27 is located above the conveyor belt , the pallet 28 placed on the conveyor belt is positioned.

[0033] A steel wire rope is respectively connected on the two conveyor frame side plates 34, and the other end of the steel rope is connected to the counterweight 32 through the pulley block 30. A balance weight 37 is mounted on one end of the mounting base 25 .

[0034] A control unit 4 is installed on one side of the frame 1, and a PLC control circuit is used, and a touch screen is used for input and output. The parameters are changed according to production requirements, and different products are produced through different speed ratios of each servo motor.

[0035]It can be seen from the above-described embodiments that the pastry product processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com