Novel solid foam gun

A foam gun, solid technology, applied in fire rescue, etc., can solve the problems of uncontrollable weight and length of fire extinguishing gun, blockage of water outlet by solid foam sticks, affecting fire extinguishing efficiency, etc., to achieve controllable foaming multiple and spray distance, The effect of convenient loading and strong maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

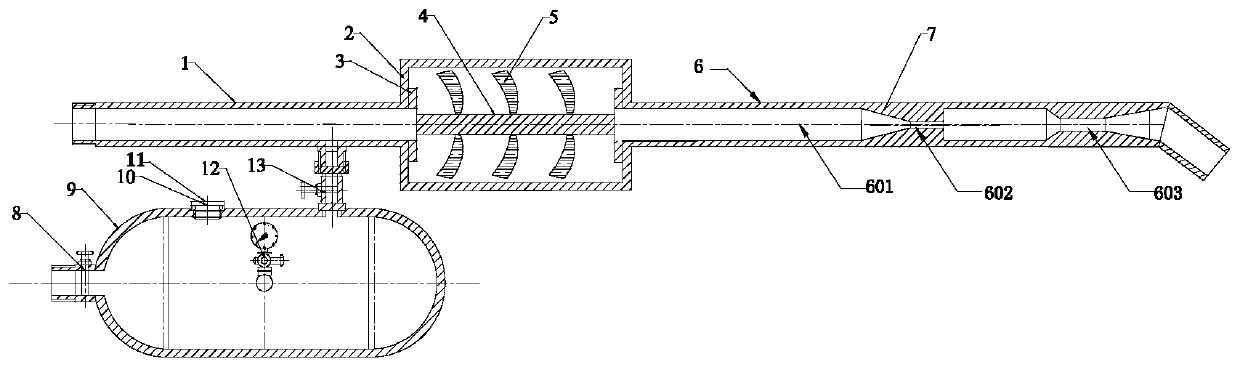

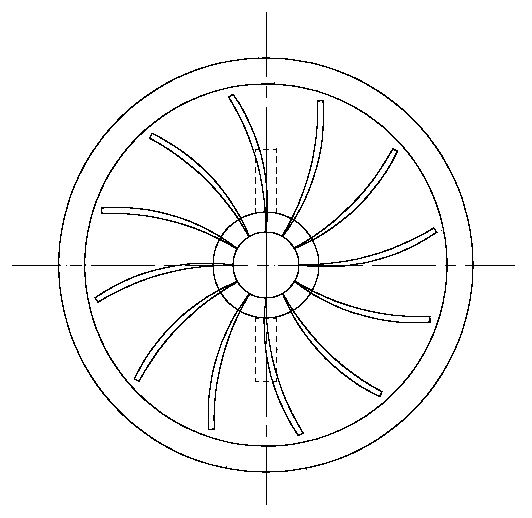

[0039] Embodiment 1 provides a kind of novel solid foam gun, as figure 1 As shown, it includes a dissolution accelerator tank 2, the dissolution accelerator tank 2 is a hollow cylinder, one end of the outside is connected with a water inlet pipe 1, and the other end of the outside is connected with an outlet pipeline 6; The ends are respectively connected with bearing brackets 3, and the bearing brackets 3 are connected together with the inner two ends of the dissolution accelerator tank body 2 through threads, and the turbine bearing 4 is housed in the dissolution accelerator tank body 2, and the turbine bearing 4 passes through its two ends. The bearing bracket 3 at the end is fixed inside the tank body 2 of the dissolution accelerator, and the turbine blades 5 and the turbine bearings 4 are connected together by welding; the turbine blades 5 are alternately arranged on the turbine bearings 4; the bottom of the water inlet pipe 1 A solid foam storage tank 9 is connected to a...

Embodiment 2

[0044] Embodiment 2 provides a kind of novel solid foam gun, as figure 1 As shown, it includes a dissolution accelerator tank 2, the dissolution accelerator tank 2 is a hollow cylinder, one end of the outside is connected with a water inlet pipe 1, and the other end of the outside is connected with an outlet pipeline 6; The ends are respectively connected with bearing brackets 3, and the bearing brackets 3 are connected together with the inner two ends of the dissolution accelerator tank body 2 through threads, and the turbine bearing 4 is housed in the dissolution accelerator tank body 2, and the turbine bearing 4 passes through its two ends. The bearing bracket 3 at the end is fixed inside the tank body 2 of the dissolution accelerator, and the turbine blades 5 and the turbine bearing 4 are connected together by welding; the turbine blades 5 are arranged in parallel on the turbine bearing 4; the bottom end of the water inlet pipe 1 A solid foam storage tank 9 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com