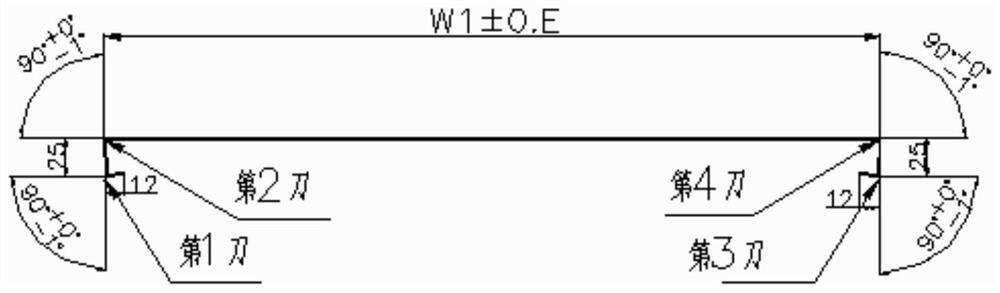

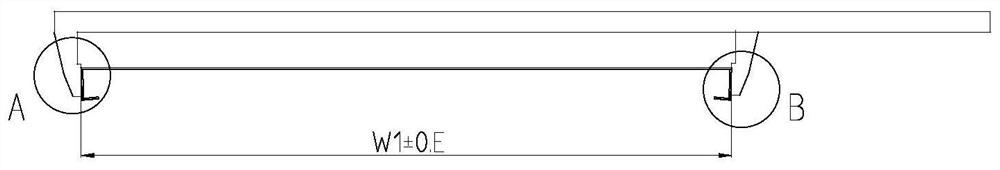

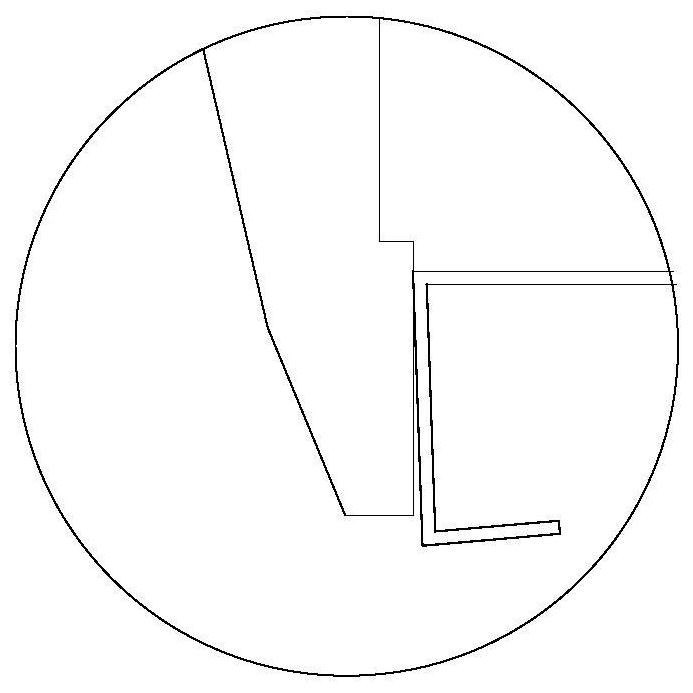

A control method for elevator car wall width error and assembly error

A control method and technology of elevator car, which are applied to elevators, manufacturing tools, transportation and packaging in buildings, etc., can solve the problems of inconsistent bending datum error, material hardness and thickness influence error, bending positioning backing error, etc. Achieve the effect of reducing bending width error and system error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: As shown in the attached drawing, the measurement structure of the width error and assembly error of the elevator car wall mainly includes the car wall raw material 1, the lower bending mold 2, the upper bending mold 3, and the center equipment of the upper and lower bending molds Origin point 0 position 4. Raw material pushing preload and width detection sensor part 5. Bending positioning grid moving system 6. Car wall moving direction 7. Car wall length is 2-3m and is pushed and pre-loaded by two independent raw materials The pressure and width detection sensor part 5 and the bending positioning barrier moving system 6 are composed. The car wall raw material 1 is driven by a flat belt to provide linear movement power, and a single independent raw material is pushed to tighten the pre-pressure and width detection sensor part 5 and the bending positioning barrier. The linear movement of the moving system 6 is provided by the slider servo mechanism, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com