Instrument and method for testing mechanical property of materials under tension-torsion composite-force-thermal coupling working conditions

A material mechanics and testing instrument technology, applied in scientific instruments, using stable torsional force to test material strength, instruments, etc., can solve the problem of physical field loading coupling, inability to observe in situ and mechanical load loading, and a single type of loading load and other problems, to achieve the effect of compact structure, high coaxiality and good neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

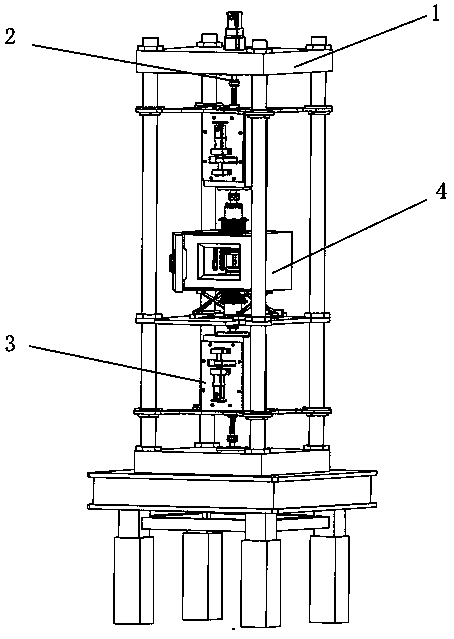

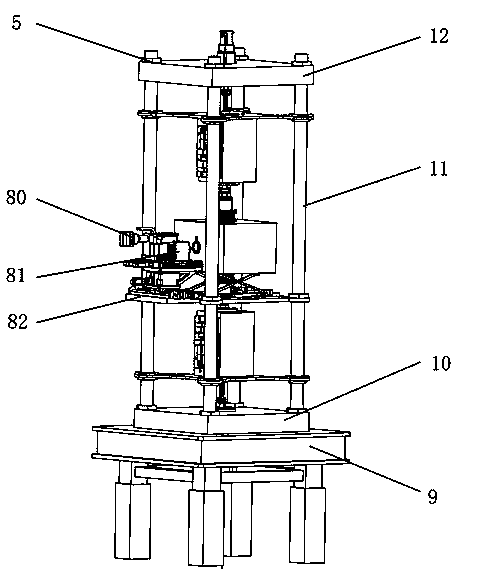

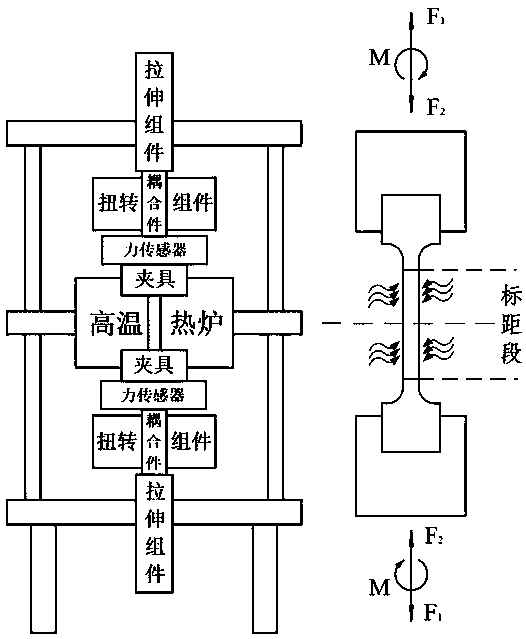

[0036] see Figure 1 to Figure 9 As shown, the instrument and method for testing the mechanical properties of materials under the tension-torsion composite-force-heat coupling working condition of the present invention mainly include: a support module 1, a tensile loading module 2, a torsional loading module 3, a high temperature loading module 4 and In situ monitoring module. Among them, the support module 1 is the structural support of the entire test equipment. It adopts the layout scheme of vertical four columns, which is convenient for clamping and positioning, and it is convenient to carry the in-situ monitoring module for testing under complex working conditions. It is in line with the multi-factor coupling module. The design idea is based on the concept; the tensile loading module 2 is driven by an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com