Automatic cable processing system and method

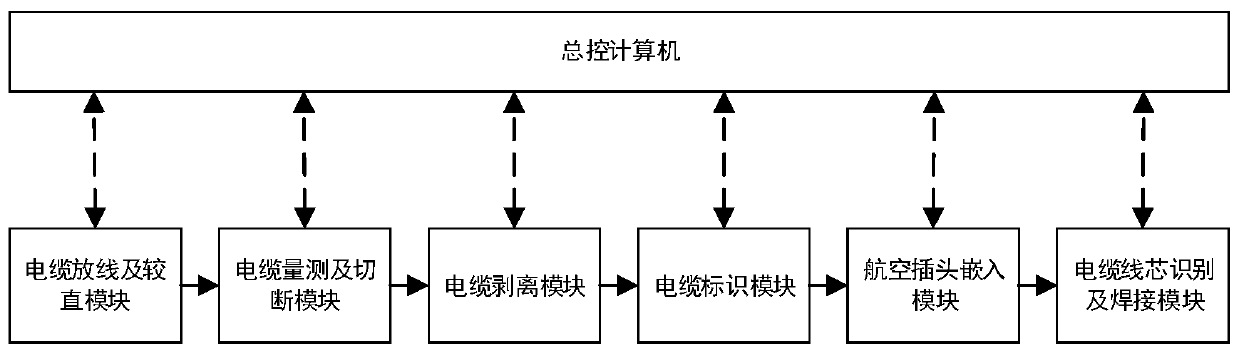

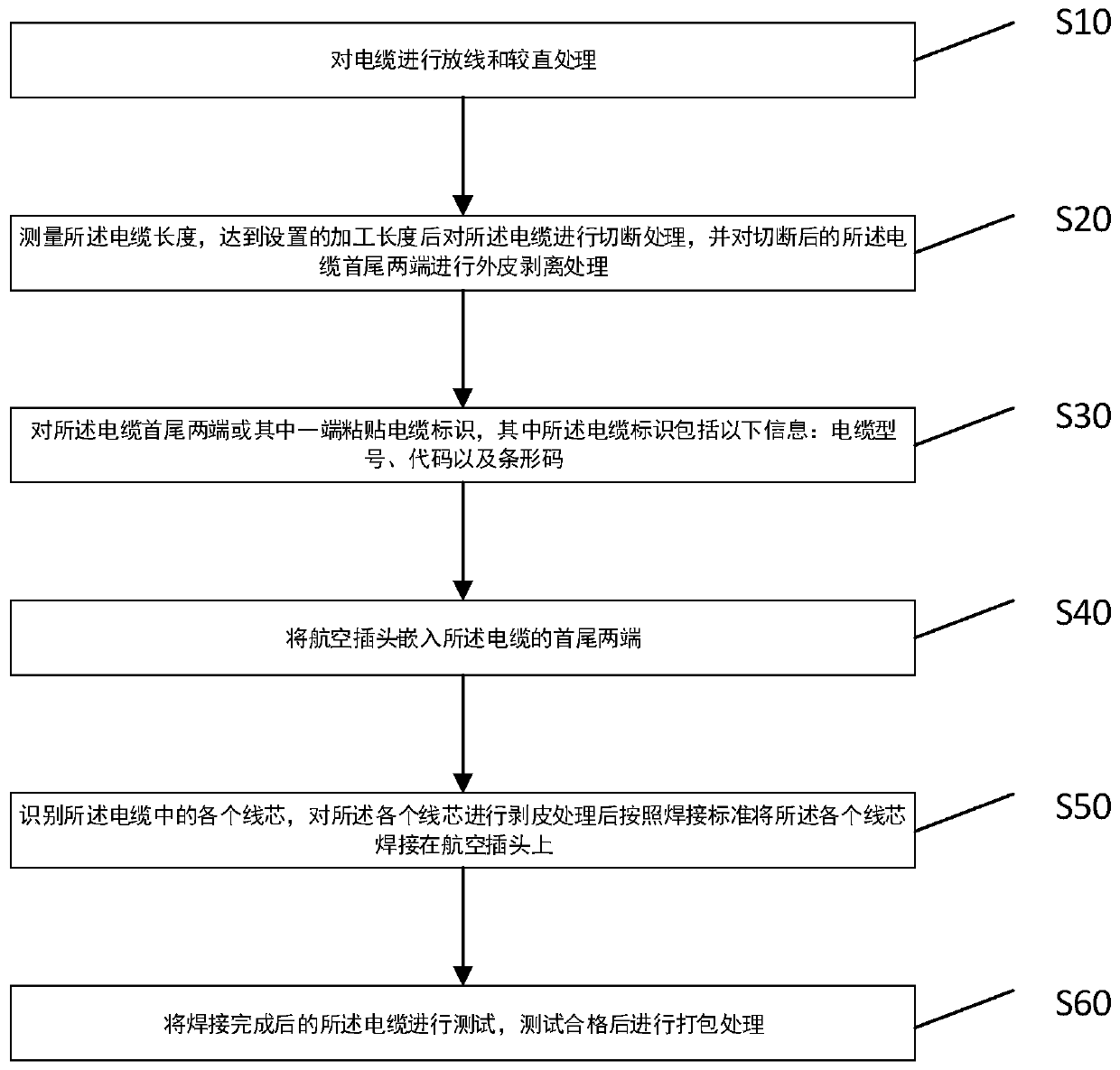

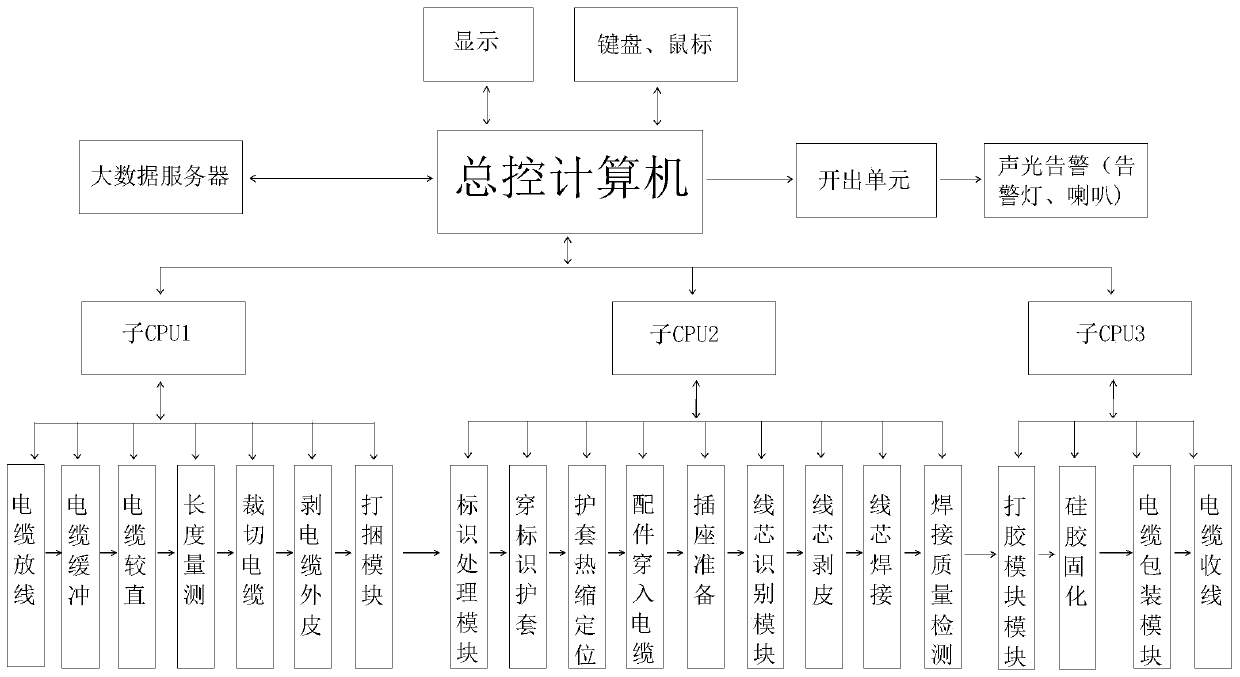

An automatic processing and cable technology, applied to circuits, electrical components, circuit/collector parts, etc., can solve the problem of large proportion of manual operation, difficulty in distinguishing color and thickness of wire cores, and failure to peel single-core wires inside the cable. , welding, gluing and other problems, to achieve the effect of easy fixing, eliminating discrimination errors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The idea, specific structure and technical effects of the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, scheme and effect of the present invention.

[0029] It should be noted that, unless otherwise specified, when a feature is called "fixed" or "connected" to another feature, it can be directly fixed and connected to another feature, or indirectly fixed and connected to another feature. on a feature. In addition, descriptions such as up, down, left, and right used in the present disclosure are only relative to the mutual positional relationship of the components of the present disclosure in the drawings. As used in this disclosure, the singular forms "a", "the", and "the" are intended to include the plural forms as well, unless the context clearly dictates otherwise. Also, unless defined otherwise, all technical and scientific terms used herein have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com