Alkali lignin and polylactic resin composite environmentally-friendly plate and preparation method thereof

A technology of polylactic acid resin and alkali lignin, which is applied in the field of building materials, can solve the problems of poor water resistance, poor mechanical properties, and environmental protection of wood-based panels, and achieve good sound insulation effects, high strength, and reduced usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

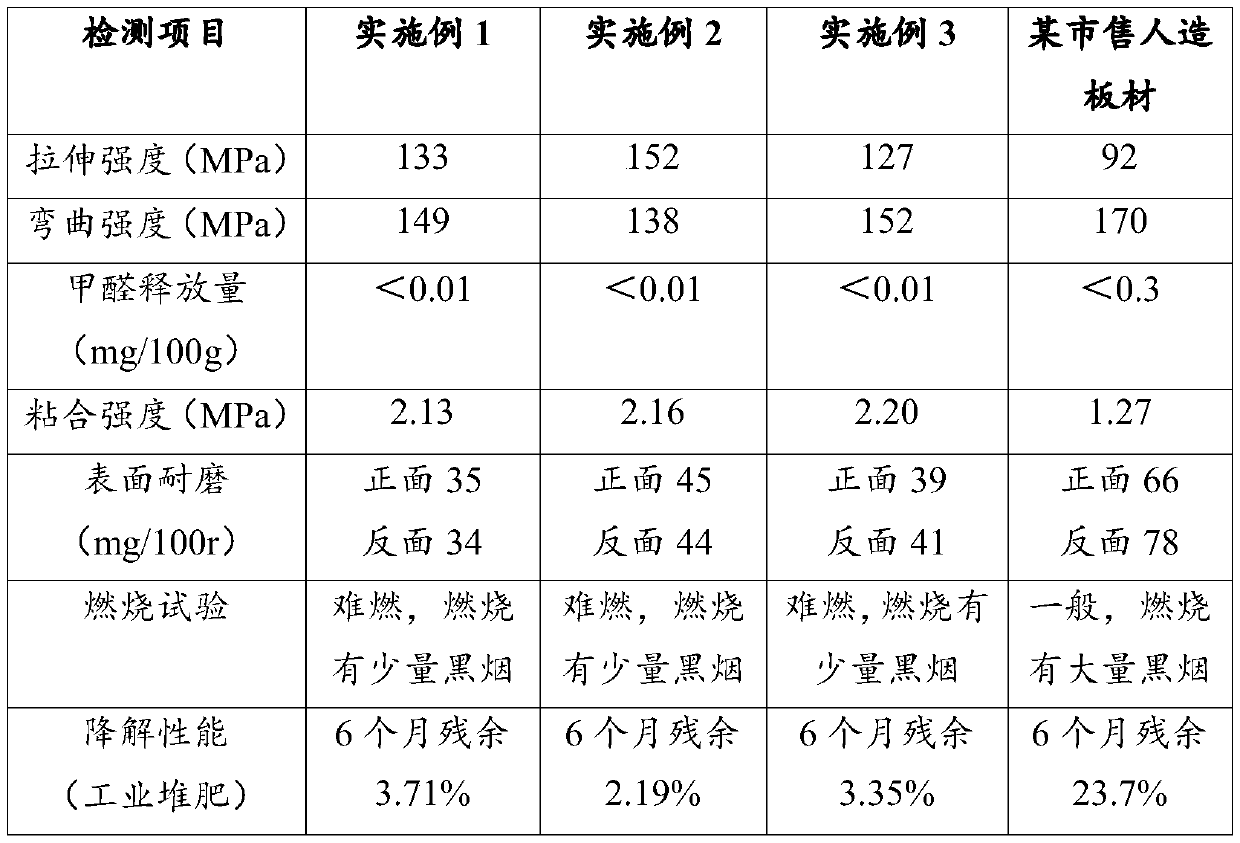

Examples

Embodiment 1

[0031] This embodiment provides an alkali lignin polylactic acid resin composite environmental protection board, which includes a first outer layer, a buffer layer, an inner layer, and a second outer layer that are sequentially stacked, and has a 4-layer structure;

[0032] The first outer layer is made of the following raw materials in parts by weight: 40 parts of alkali lignin polylactic acid resin particles, 5 parts of talcum powder, 5 parts of silicon dioxide, 3 parts of kaolin, 7 parts of calcium sulfate, and 40 parts of polylactic acid resin particles ;

[0033] The buffer layer is made of the following raw materials in parts by weight: 60 parts of alkali lignin polylactic acid resin particles, 20 parts of calcium sulfate, and 20 parts of polylactic acid resin particles;

[0034] The inner layer is made of the following raw materials in parts by weight: 70 parts of alkali lignin polylactic acid resin particles, 15 parts of calcium sulfate, and 15 parts of polylactic acid...

Embodiment 2

[0048] This embodiment provides an alkali lignin polylactic acid resin composite environmental protection board, which includes a first outer layer, a buffer layer, an inner layer, and a second outer layer that are sequentially stacked, and has a 4-layer structure;

[0049] The first outer layer is made of the following raw materials in parts by weight: 45 parts of alkali lignin polylactic acid resin particles, 8 parts of talcum powder, 7 parts of silicon dioxide, 8 parts of kaolin, 7 parts of calcium sulfate, and 25 parts of polylactic acid resin particles ;

[0050] The buffer layer is made of the following raw materials in parts by weight: 55 parts of alkali lignin polylactic acid resin particles, 25 parts of calcium sulfate, and 20 parts of polylactic acid resin particles;

[0051] The inner layer is made of the following raw materials in parts by weight: 70 parts of alkali lignin polylactic acid resin particles, 20 parts of calcium sulfate, and 10 parts of polylactic acid...

Embodiment 3

[0065] This embodiment provides an alkali lignin polylactic acid resin composite environmental protection board, which includes a first outer layer, a buffer layer, an inner layer, and a second outer layer that are sequentially stacked, and has a 4-layer structure;

[0066] The first outer layer is made of the following raw materials in parts by weight: 45 parts of alkali lignin polylactic acid resin particles, 8 parts of talcum powder, 8 parts of silicon dioxide, 7 parts of kaolin, 7 parts of calcium sulfate, and 25 parts of polylactic acid resin particles ;

[0067] The buffer layer is made of the following raw materials in parts by weight: 55 parts of alkali lignin polylactic acid resin particles, 25 parts of calcium sulfate, and 10 parts of polylactic acid resin particles;

[0068] The inner layer is made of the following raw materials in parts by weight: 65 parts of alkali lignin polylactic acid resin particles, 15 parts of calcium sulfate, and 20 parts of polylactic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com