Material transfer device for ceramic tile production

A transfer device and ceramic tile technology, which is applied in the direction of hoisting device, transportation and packaging, lifting equipment braking device, etc., can solve the problems of material box shaking and ceramic tile damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

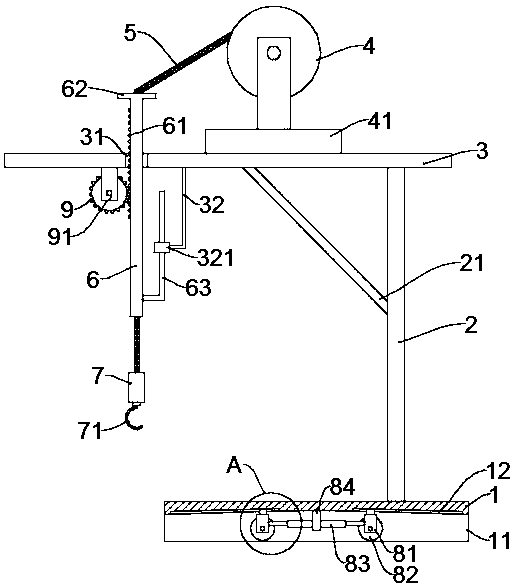

[0023] see Figure 1~4 , in an embodiment of the present invention, a material transfer device for ceramic tile production, comprising a base 1, a stand 2 fixed to the base 1, and a top plate 3 fixed to the top of the stand 2, the bottom of the base 1 is provided with a moving mechanism, and the top plate 3 is provided with a hoist 4, the hoist 4 is installed on the top plate 3 through the base 41, and the drum periphery of the hoist 4 is wound with a traction rope 5. During work, the hoist 4 lifts the material box through the traction rope 5, and then reuses The moving mechanism carries out the transfer of materials.

[0024] Further, diagonal stays 21 are fixed between the stand 2 and the top plate 3 to improve the connection strength of the structure.

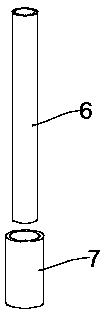

[0025] The top plate 3 is provided with a perforation 31, and a movable sleeve 6 is slid through the perforation 31. The two ends of the movable sleeve 6 are open and the movable sleeve is arranged on the periphery of the t...

Embodiment 2

[0031] The embodiment of the present invention describes the moving mechanism in detail on the basis of Embodiment 1, specifically:

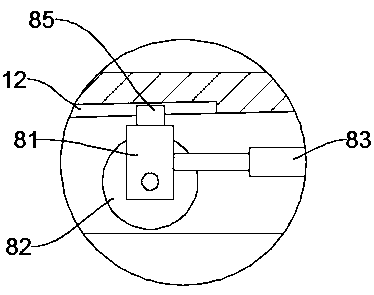

[0032] The moving mechanism is installed in the groove 11 provided at the bottom of the base 1. The moving mechanism includes a fixed plate 84 and telescopic devices 83 symmetrically installed on both sides of the fixed plate 84. One side of the movable end of the telescopic device 83 is against a Mounting frame 81, roller 82 is installed on the mounting frame 81, and the top of described mounting frame 81 is provided with slide block 85, and slide block 85 slides and is set in the chute 12 that is offered at groove 11 tops, and described chute 12 The distance between the lower surface of the base 1 decreases sequentially from the inside to the outside. When the telescopic device 83 is at the minimum travel position, the lower wheel surface of the roller 82 is higher than the lower surface of the base 1. When the telescopic device 83 drives the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap