A liquid composite spring push-pull vacuum liquid injection machine and liquid injection method

A composite spring, push-pull technology, applied in the direction of liquid distribution, transportation or transfer devices, structural parts, battery pack components, etc., can solve the problem of insufficient gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

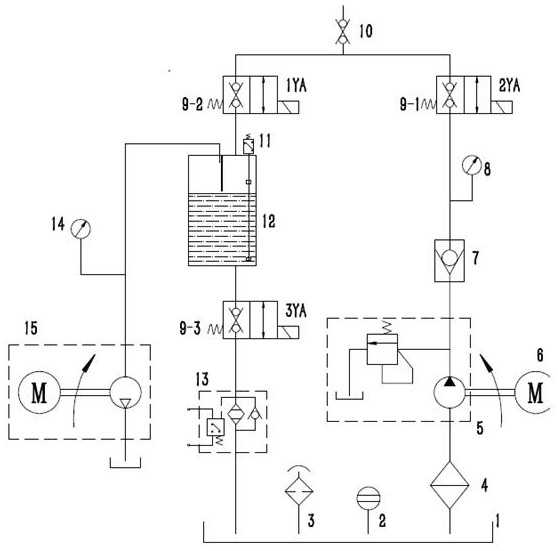

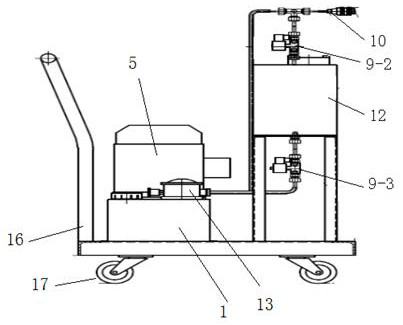

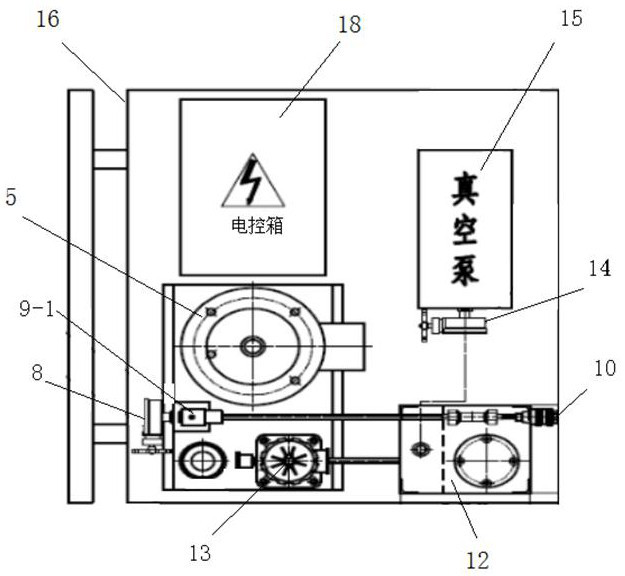

[0023] Please refer to figure 1 , figure 2 and image 3 , a liquid compound spring push-pull vacuum liquid injection machine, including a fuel tank 1, a liquid level gauge 2, an air filter 3, an oil suction filter 4, a high-pressure water pump 5, a motor 6, a one-way valve 7, and high-pressure water pump electrical contacts Pressure gauge 8, high-pressure water pump solenoid valve 9-1, vacuum pump solenoid valve 9-2, drain solenoid valve 9-3, vacuum quick change joint 10, liquid level gauge 2 11, gas-liquid separator 12, oil return filter 13. Electric contact vacuum pressure gauge 14, vacuum pump 15, vehicle frame 16, roller 17, electric control box 18. The vacuum pump is connected to the gas-liquid separator through the pipeline, the gas-liquid separator is connected to the vacuum pump solenoid valve through the pipeline, and the vacuum pump solenoid valve is connected to the vacuum quick change joint through the pipeline; the bottom of the gas-liquid separator is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com