A kind of purification method of nicotine and nicotine

A purification method and technology of nicotine, which is applied in the field of purification of natural products, and can solve the problems of heavy chemical odor, yellowish color and unstable properties of nicotine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

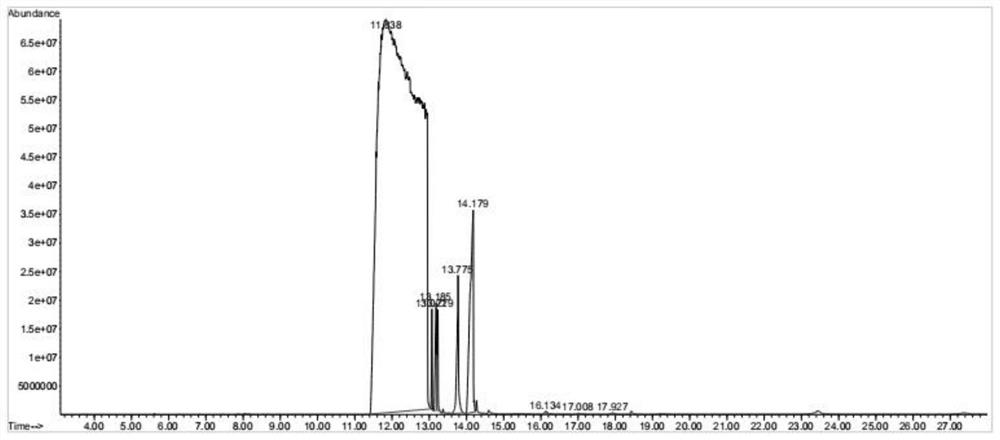

Embodiment 1

[0047] The purification method of nicotine of the present embodiment comprises the following steps:

[0048] 1) Put 25L nicotine into a 30L rectification reaction kettle, set the temperature at 90°C, carry out under normal pressure, set the reflux ratio to full outflow, keep the nicotine in the reaction kettle without boiling, and use a blower device to continuously ventilate Inject nitrogen, keep a certain amount of fresh nitrogen circulating in the rectification equipment, and continue for 3 hours, so that low-boiling substances such as organic solvents are continuously heated and volatilized, and flow out with the airflow;

[0049] 2) The nicotine after atmospheric distillation is divided into two steps for vacuum distillation. The first step of distillation raises the rectification temperature to 110°C, the vacuum degree is 0.08Mpa, the reflux ratio is set to full outflow, and the distillation time is 40min. There is no obvious oil on the wall of the glass tube (residual o...

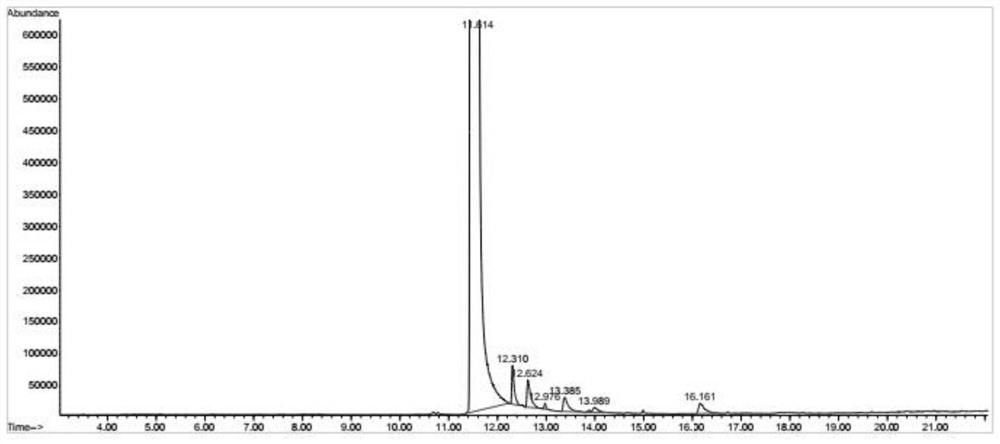

Embodiment 2

[0069] The purification method of nicotine of the present embodiment comprises the following steps:

[0070] 1) Put 25L of nicotine into a 30L rectification reaction kettle, set the temperature at 100°C, carry out under normal pressure, set the reflux ratio to full outflow, keep the nicotine in the reaction kettle from boiling, and use a blower device to continuously ventilate Inject nitrogen, and keep a certain amount of fresh nitrogen circulating in the rectification equipment for 4 hours, so that low-boiling substances such as organic solvents are continuously heated and volatilized, and flow out with the airflow;

[0071] 2) The nicotine after atmospheric distillation is divided into two steps for vacuum distillation. The first step of distillation raises the rectification temperature to 120°C, the vacuum degree is 0.085Mpa, and the distillation time is 1h. At this time, there is no obvious oil on the glass tube wall The residual nicotine (residual organic solvents such as...

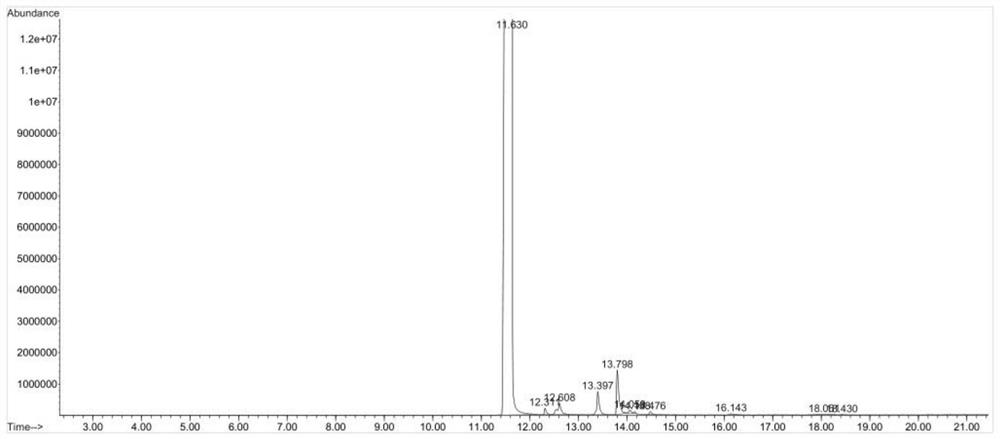

Embodiment 3

[0076] The purification method of nicotine of the present embodiment comprises the following steps:

[0077] 1) Put 25L of nicotine into a 30L rectification reaction kettle, set the temperature at 100°C, carry out under normal pressure, set the reflux ratio to full outflow, keep the nicotine in the reaction kettle from boiling, and use a blower device to continuously ventilate Inject argon, keep a certain amount of fresh nitrogen circulating in the rectification equipment, and continue for 5 hours, so that the organic solvent and other low boiling point substances are continuously heated and volatilized, and flow out with the air flow;

[0078] 2) The nicotine after atmospheric distillation is divided into two steps for vacuum distillation. The first step of distillation raises the rectification temperature to 150°C, the vacuum degree is 0.085Mpa, and the distillation time is 30min. At this time, there is no obvious oil on the glass tube wall The residual nicotine (residual or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com