A kind of preparation method of waste textile fiber non-woven coating material

A technology of textile fibers and coating materials, applied in textiles and papermaking, fiber treatment, wear-resistant fibers, etc., to achieve the effects of changing surface structure, saving energy, and improving printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

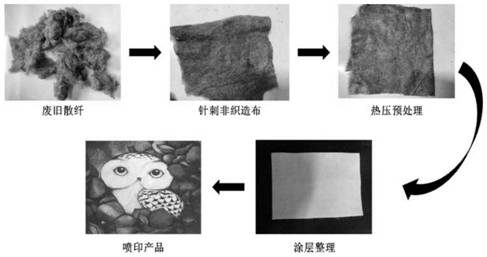

[0027] 1) Preparation of waste textile fiber nonwovens suitable for coating processing: sterilize the waste textiles through disinfection equipment, send the sterilized waste textiles into an opening machine for opening treatment to obtain waste textile fibers, and use needle punching The equipment produces waste textile fiber nonwovens through the steps of carding, fine combing, stacking, acupuncture, hot pressing, etc., and preheats and presses the obtained waste textile fiber nonwovens. The process is as follows: the temperature is 180 ° C, The pressure is 20Mpa, the time is 90s, and the waste textile fiber nonwoven fabric suitable for coating processing is obtained.

[0028] 2) Preparation of coating material: 35 parts of anhydrous calcium chloride and 100 parts of anhydrous methanol were fully stirred and mixed at a temperature of 65°C. After the reaction was completed, 40 parts of nylon waste silk was added for dissolution, and the waste After the silk is completely diss...

Embodiment 2

[0030] 1) Preparation of waste textile fiber nonwovens suitable for coating processing: sterilize the waste textiles through disinfection equipment, send the sterilized waste textiles into an opening machine for opening treatment to obtain waste textile fibers, and mix them with 4 % low-melting point polyester fiber, with the help of needle punching equipment, the waste textile fiber nonwoven fabric is prepared through the steps of carding, fine carding, web stacking, needle punching, hot pressing, etc., and the obtained waste textile fiber nonwoven fabric is preheated and pressed The treatment process is as follows: the temperature is 140° C., the pressure is 30 MPa, and the time is 240 s to obtain a waste textile fiber nonwoven fabric suitable for coating processing.

[0031] 2) Preparation of coating material: 15 parts of anhydrous calcium chloride and 60 parts of anhydrous methanol were fully stirred and mixed at a temperature of 65°C. After the reaction was completed, 10 p...

Embodiment 3

[0033] 1) Preparation of waste textile fiber nonwovens suitable for coating processing: sterilize the waste textiles through disinfection equipment, send the sterilized waste textiles into an opening machine for opening treatment to obtain waste textile fibers, and mix them with 3 % low-melting point polyester fiber, with the help of needle punching equipment, the waste textile fiber nonwoven fabric is prepared through the steps of carding, fine carding, web stacking, needle punching, hot pressing, etc., and the obtained waste textile fiber nonwoven fabric is preheated and pressed The treatment process is as follows: the temperature is 200° C., the pressure is 10 MPa, and the time is 60 s to obtain a waste textile fiber nonwoven fabric suitable for coating processing.

[0034] 2) Preparation of coating material: 25 parts of anhydrous calcium chloride and 100 parts of anhydrous methanol are fully stirred and mixed at a temperature of 65°C. After the reaction is completed, 20 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com