Efficient anti-chassis icing fin heat exchanger and working method thereof

A technology of a fin heat exchanger and a working method, which is applied to heat exchange equipment, lighting and heating equipment, damage protection, etc. The effect of eliminating icing and frosting, improving heat production and energy efficiency, and avoiding negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

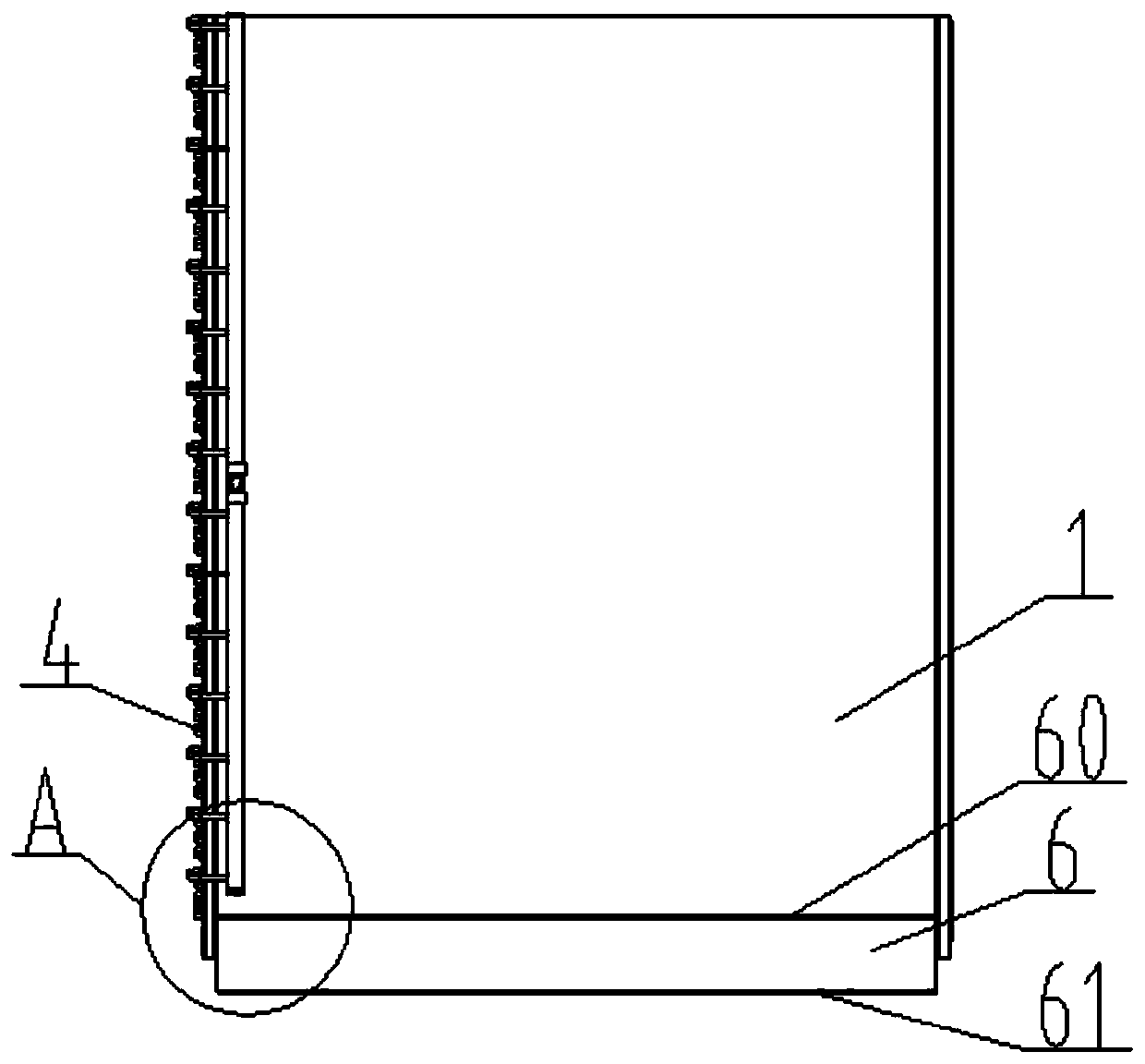

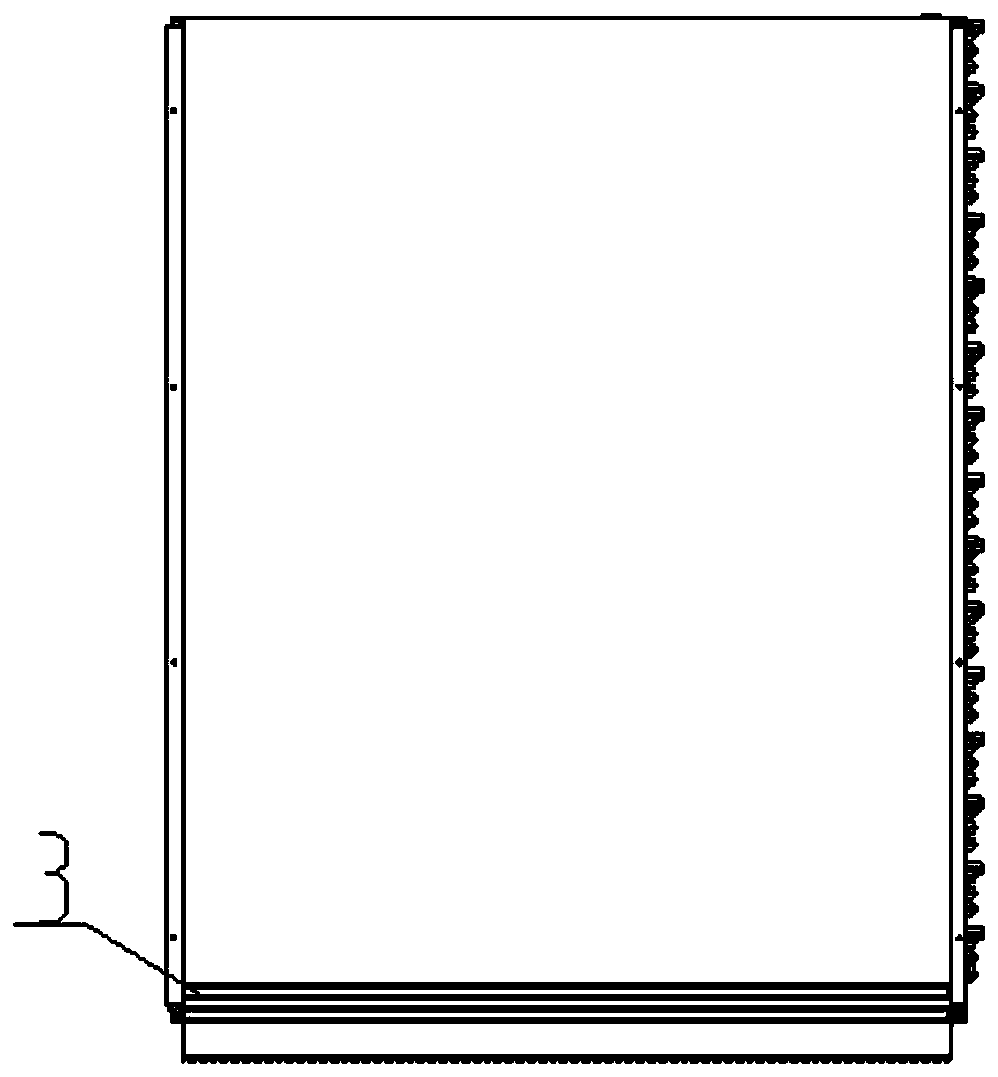

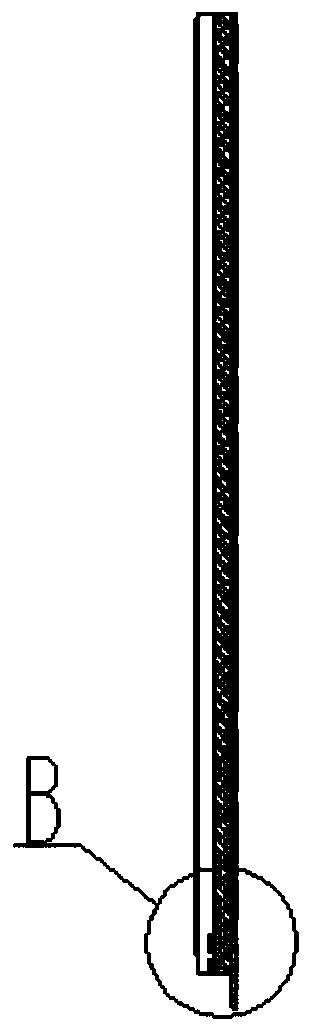

[0034] Such as Figure 1 ~ Figure 3 As shown, the present invention provides a high-efficiency anti-icing chassis fin heat exchanger, including fins 1, fin temperature sensing tubes 2, variable resistance heating belts 3, antifreeze working medium tubes 4 and cold and heat transfer heat tubes 6, A finned temperature-sensing tube 2 is provided at the bottom end of the finned tube, and a temperature-sensing probe is built in the finned temperature-sensing tube 2 . The inside of the fin 1 is coiled with an antifreeze working medium pipe 4 , one end of the antifreeze working medium pipe on the side of the fin 1 is the inlet of the antifreeze working medium pipe, and the other end is the outlet of the antifreeze working medium pipe.

[0035] One side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com