Preparation method of low-loss infrared high-nonlinearity optical waveguide

A highly nonlinear and optical waveguide technology, applied in the field of micro-nano processing and nonlinear optics, can solve the problems of large scattering, transmission band limitation, and application performance limitation, and achieve the effect of low roughness and low loss transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

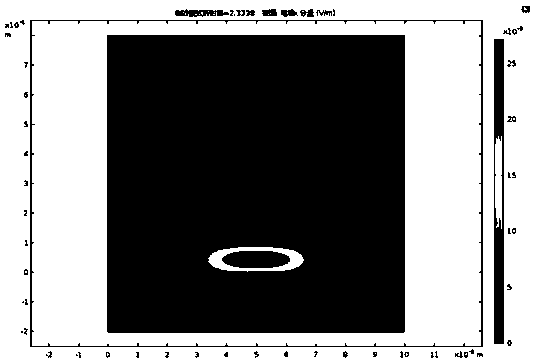

[0026] Such as Figure 4 shown, combined with Figures 1 to 5 Describe this embodiment, such as figure 1 As shown, the low-loss infrared chalcogenide optical waveguide includes: substrate silicon 201, lower cladding 202, fiber core 203, and upper cladding 204 from bottom to top; the lower cladding 202 is silicon dioxide; The core 203 on the cladding layer 202 cladding and having an incident surface and an exit surface is an infrared chalcogenide; and at least the upper cladding 204 embedded in these cores 203 is air; the refractive index of the core 203 is larger than that of the upper and lower claddings. , and the interfaces between the core 203 and the upper cladding 204 and the lower cladding 202 are smooth.

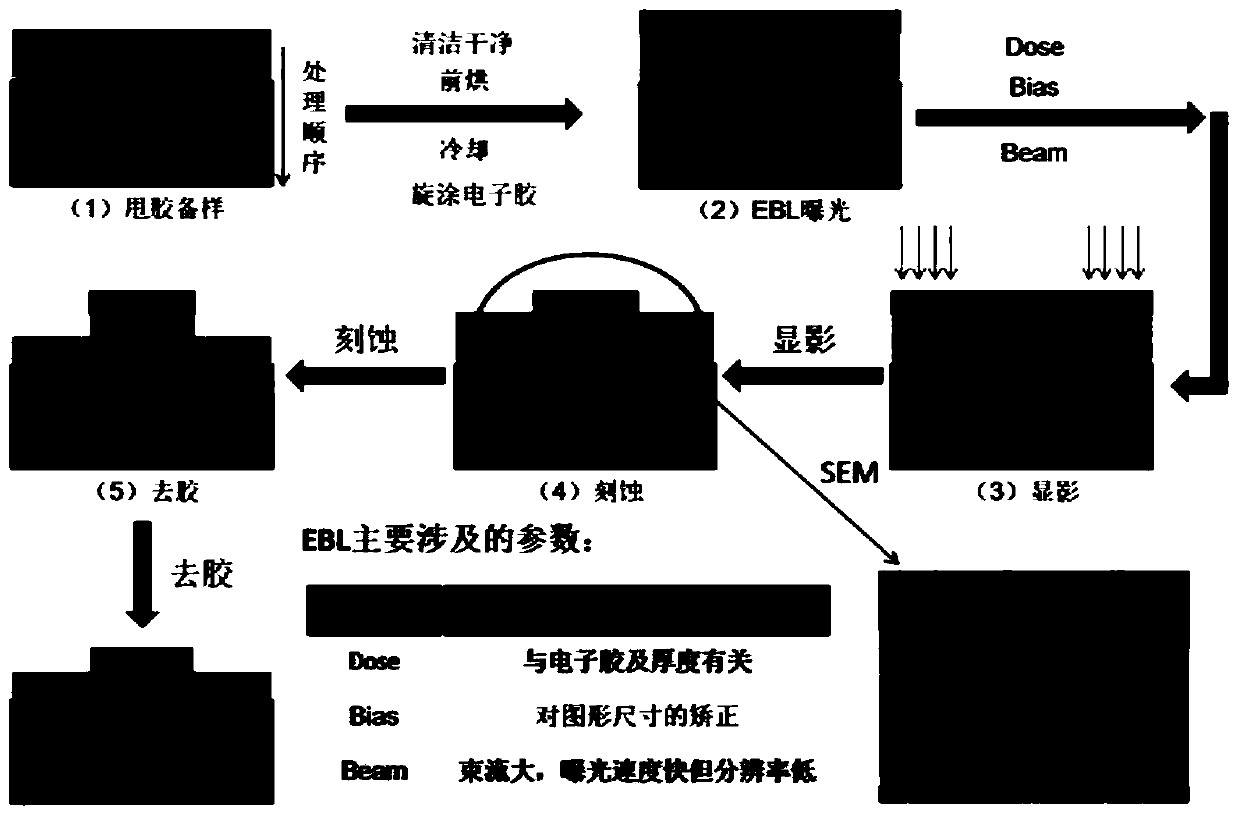

[0027] This embodiment provides a method for preparing a low-loss infrared chalcogenide waveguide, which relates to the fields of micro-nano processing and nonlinear optics, especially the transmission of low-loss light waves in waveguides. transmission characteri...

Embodiment 2

[0040] combine Figure 5 This embodiment is described. In this embodiment, the waveguide loss coefficient is obtained by comparing the input and output powers of waveguides with different lengths, and then using the difference between the output powers of two waveguides with different lengths.

[0041] The test program for the test system for waveguide loss factor consists of the following steps:

[0042] Step 1: First, place the prepared waveguide structure on an adsorption table to ensure that the structure will not shake during the test.

[0043] Step 2: Pass the lens fiber through the three-dimensional adjustment frame, roughly align it with the input and output ends of the waveguide, observe through the CCD, and then input a beam of infrared band and 10dBm light source at the input end, and connect a power meter at the output end. And through the fine adjustment of the three-dimensional adjustment frame, the lens fiber can be aligned with the input and output ports of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap