Light-transmitting box-type transformer

A box-type transformer and transformer technology, applied in the field of transformers, can solve problems such as long interval time, discount of heat resistance and insulation performance, failure of casing sealing, etc., to achieve convenient and long-lasting storage, enhanced multi-directional conduction, and good light intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

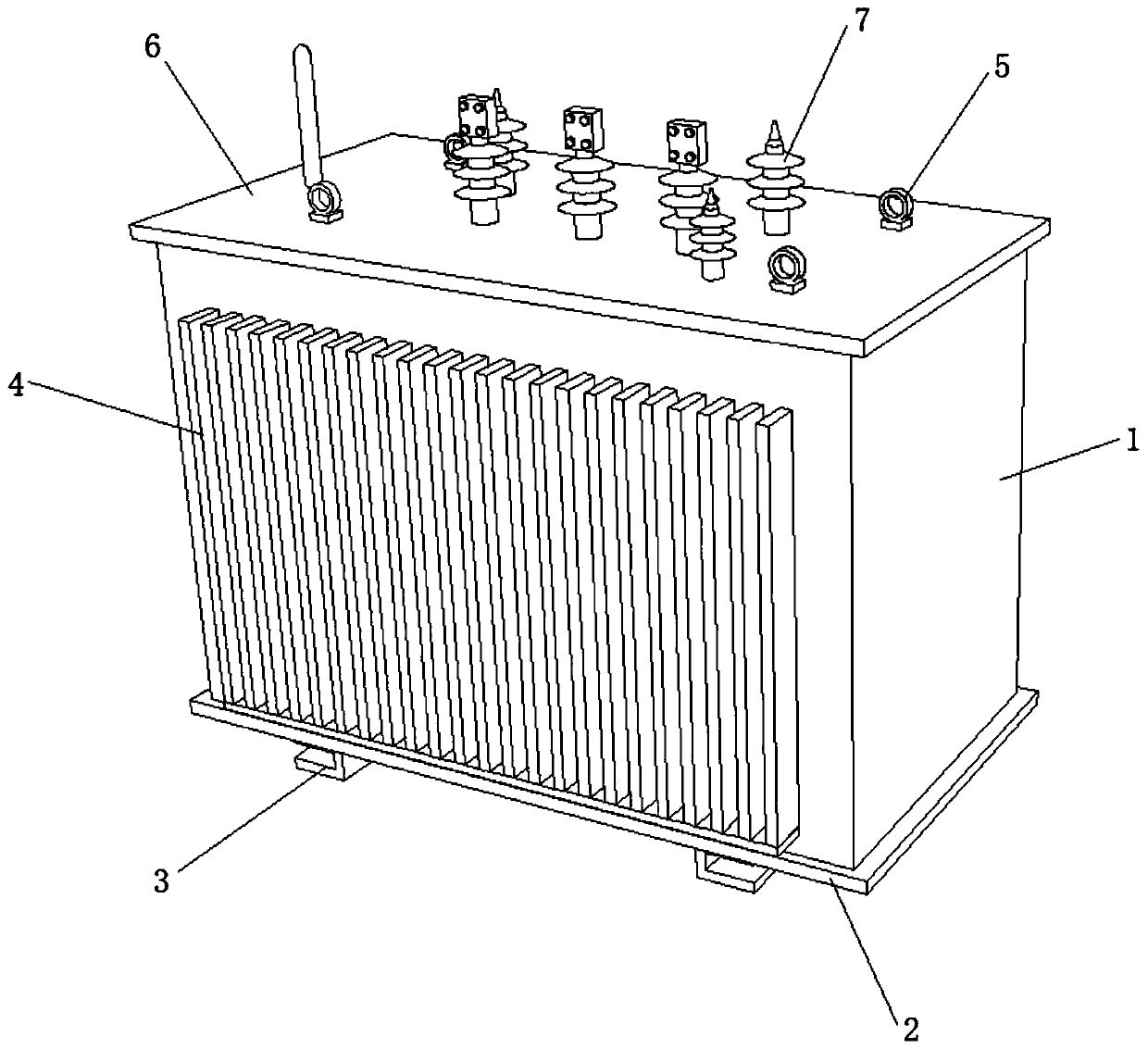

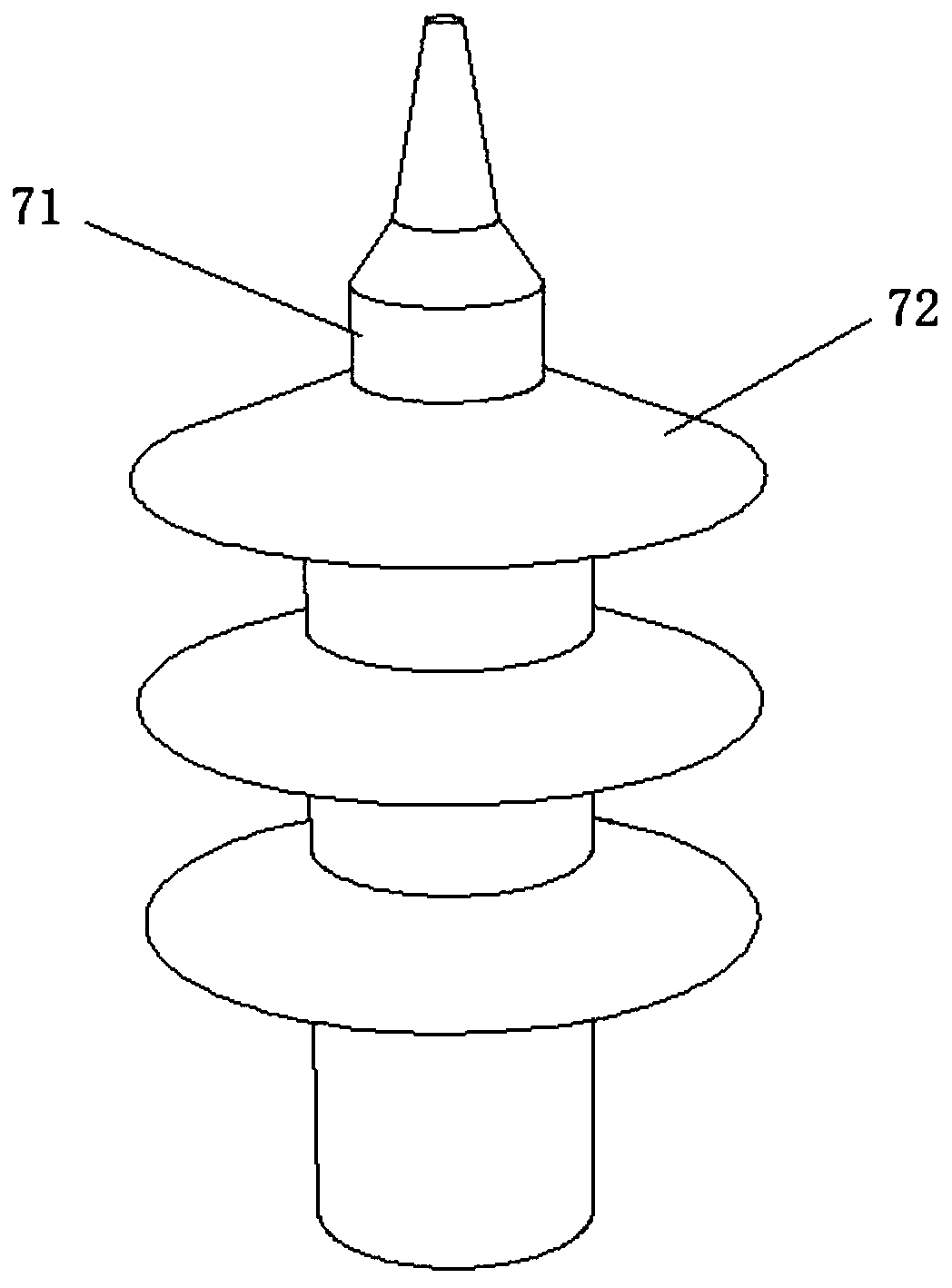

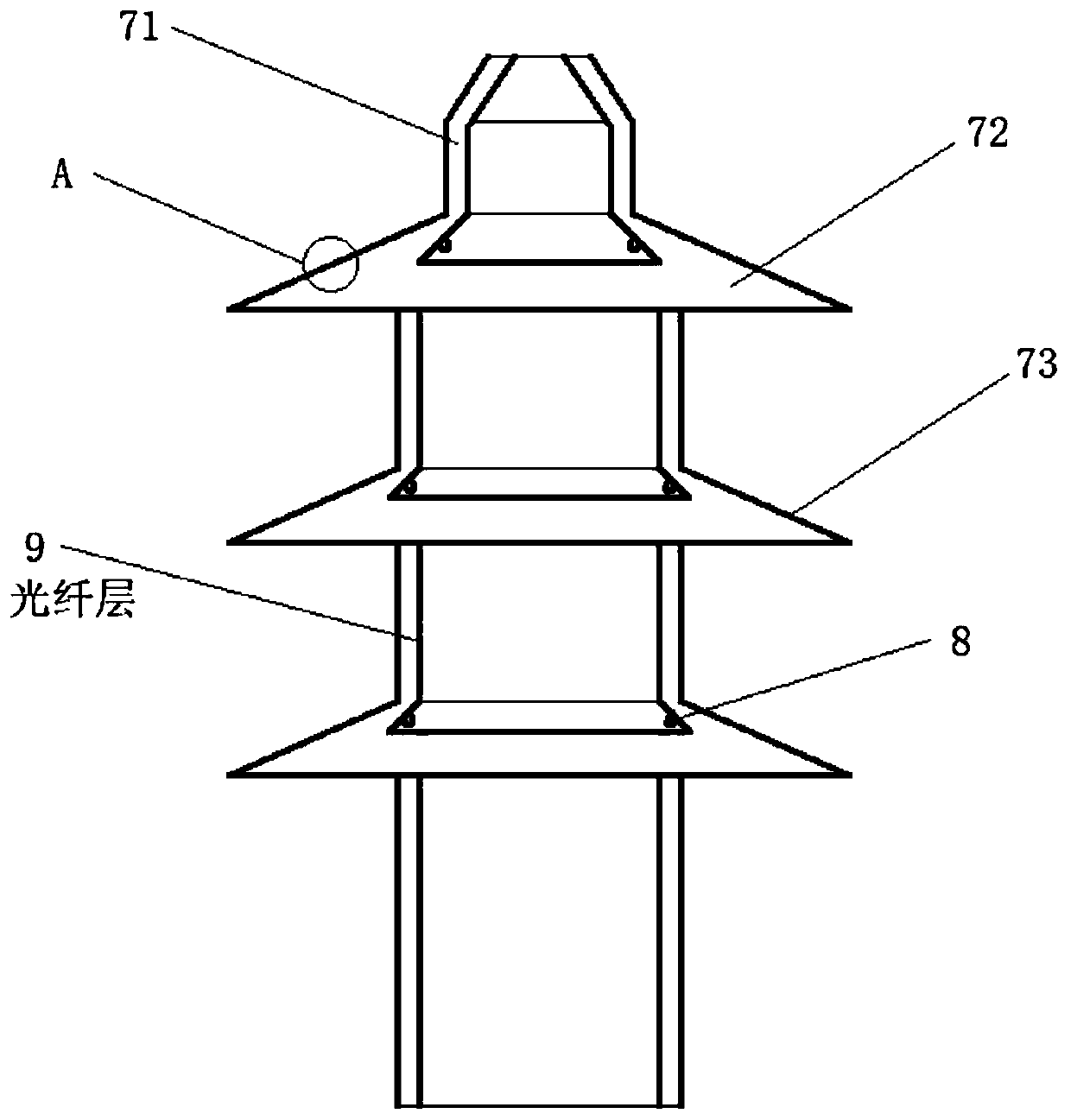

[0045] see figure 1 , a light-transmitting box-type transformer, including a transformer body 1 with a top plate 6 and a bottom plate 2 respectively installed at the upper and lower ends. hole, the side end of the transformer body 1 is fixedly connected with a plurality of evenly distributed cooling fins 4, which can promote the heat dissipation of the transformer body 1, ensure the stable operation performance of the transformer body 1, and prevent frequent failures due to excessive internal temperature, and the lower end of the bottom plate 2 is fixed Mounting feet 3 are connected to prevent the bottom plate 2 at the bottom of the transformer body 1 from directly contacting the ground, which is convenient for transportation. For example, a forklift can be inserted into the gap between the bottom plate 2 and the mounting feet 3 for transportation. The upper end of the top plate 6 is fixedly connected with multiple lifting rings 5. It is convenient for lifting equipment to lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com