A light-transmitting box-type transformer

A box-type transformer and transformer technology, applied in the field of transformers, can solve the problems of long interval time, failure of casing sealing, deterioration of thermal stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

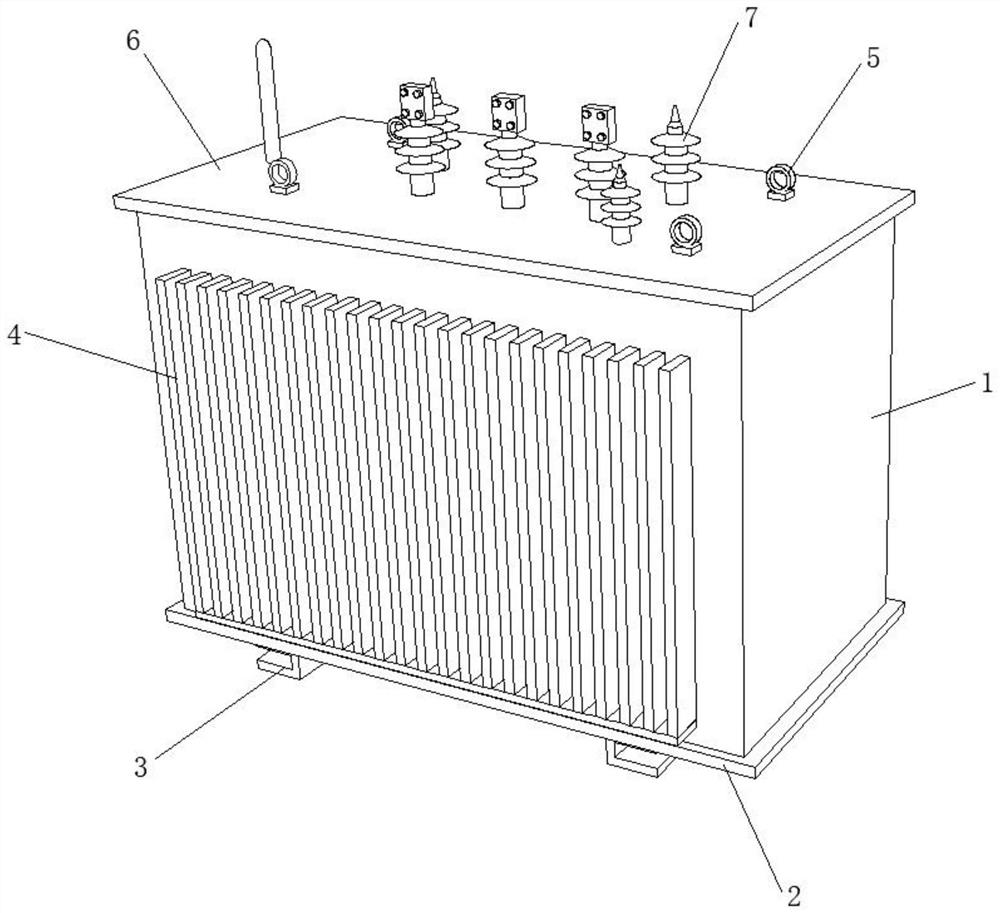

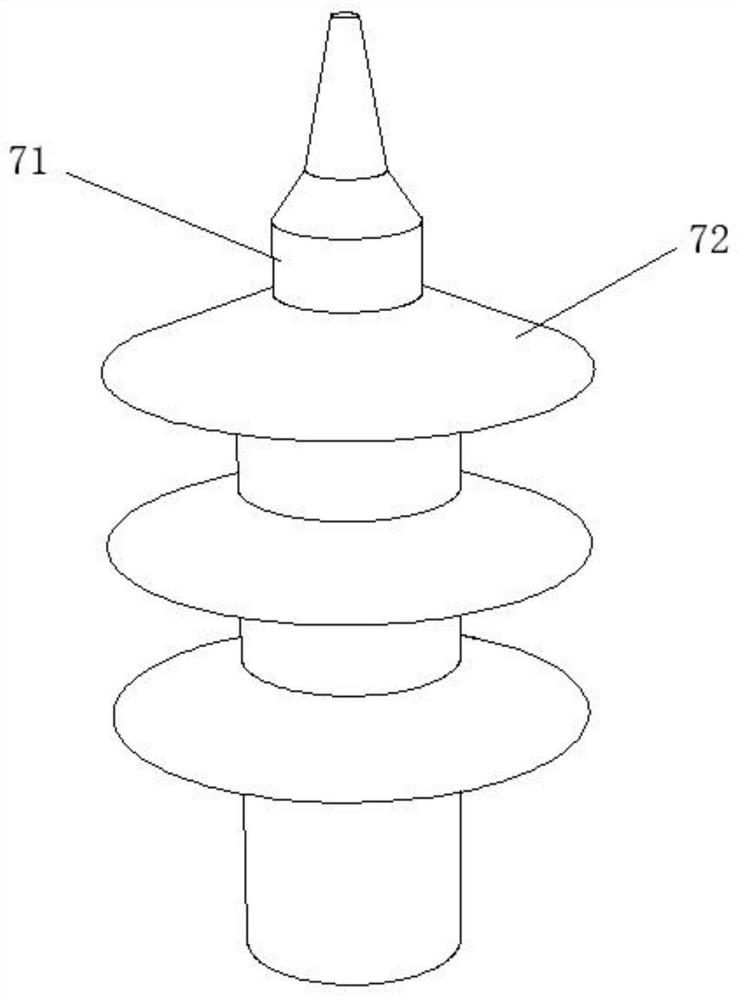

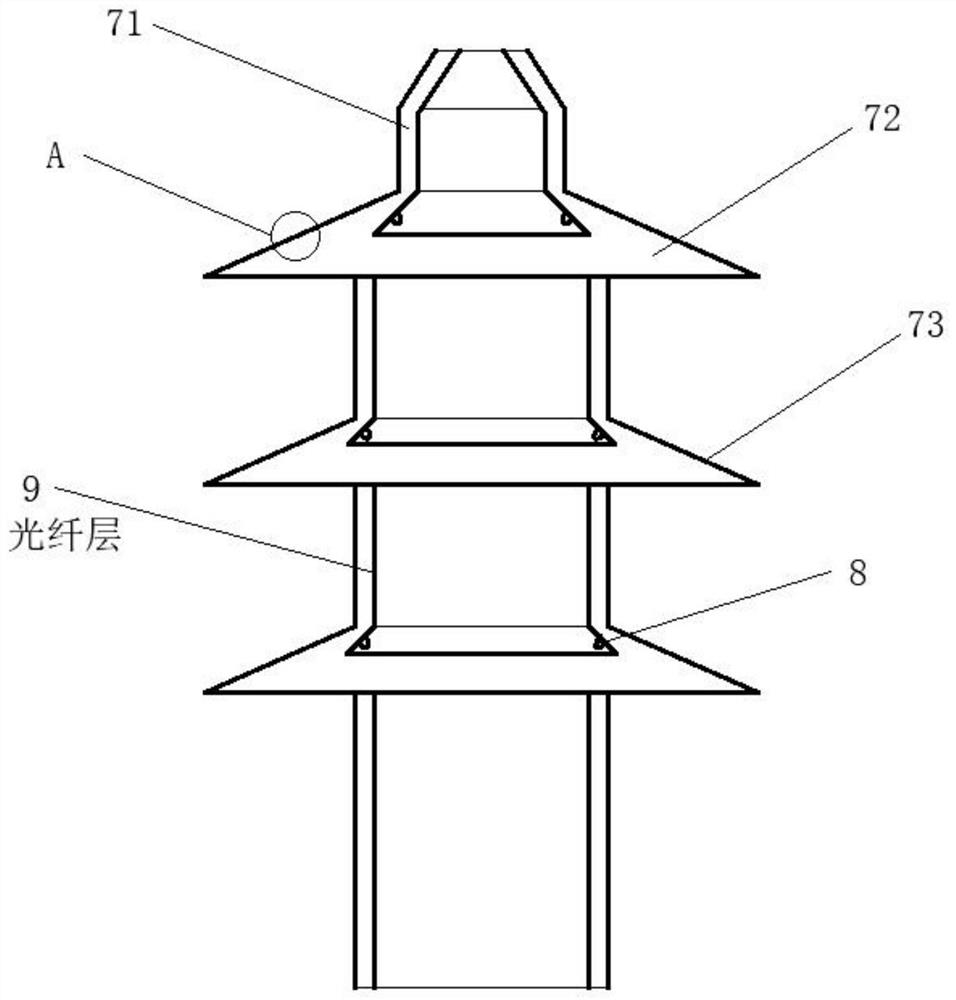

[0045] see figure 1 , a light-transmitting box-type transformer, comprising a transformer body 1 with a top plate 6 and a bottom plate 2 respectively installed at the upper and lower ends, the upper end of the transformer body 1 is connected with a bushing 7, and the top plate 6 is drilled with a bushing 7. The side end of the transformer body 1 is fixedly connected with a plurality of evenly distributed heat dissipation fins 4, which promotes the heat dissipation of the transformer body 1, ensures the stable operation performance of the transformer body 1, and is not prone to frequent failures due to its high internal temperature. The mounting feet 3 are connected to avoid direct contact between the bottom plate 2 at the bottom of the transformer body 1 and the ground, which is convenient for handling. For example, a forklift can be inserted into the gap between the bottom plate 2 and the mounting feet 3 for transportation. The upper end of the top plate 6 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com