Technology development and application processing method for improving yield of hydrogen and ethylene

A technology of ethylene yield and processing technology, which is applied in the field of technology development and application processing technology for improving the yield of hydrogen and ethylene, can solve the problems of low hydrogen and ethylene yield, can not meet the demand of the device, increase the demand for hydrogen, etc. The effect of load, reduced running loss, increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

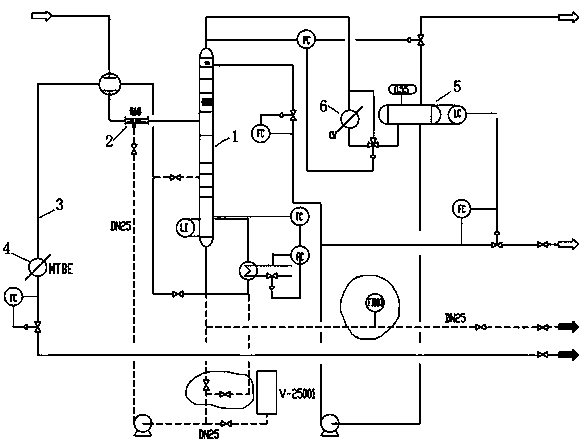

[0013] Such as figure 1 As shown, a technology development and application process for improving hydrogen and ethylene yields includes the following steps:

[0014] S1. Add cyclone separator 2 in reaction settler 1, the purpose is to separate oil gas and catalyst with higher precision, in order to avoid catalyst loss;

[0015] S2. A precooler 4 is added to the pre-lift section 3 of the riser, and the temperature is lowered from 690°C to 660°C±2°C to provide operating conditions for high agent-to-oil ratio;

[0016] S3. The absorption tower 5 is connected to the air compressor 6, and the rich gas is exported through the air compressor.

[0017] Further, the process parameters are: the reaction temperature is controlled at 550°C±2°C; the regeneration temperature is controlled at 695°C±2°C; the differential pressure between the two devices is controlled at 10KPA±3KPA; the amount of atomizing steam is controlled at 8T / H; The flow control is 1200Nm3 / h.

[0018] Further, the rich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com