Casting method and tool of crosshead slider white alloy of large low speed marine diesel engine

A technology of crosshead slider and marine diesel engine, which is applied in the field of white metal casting and connection forming, can solve the problems of white metal liquid leakage, shelling, slag inclusion, etc., and achieve the effect of slowing down the leakage speed and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

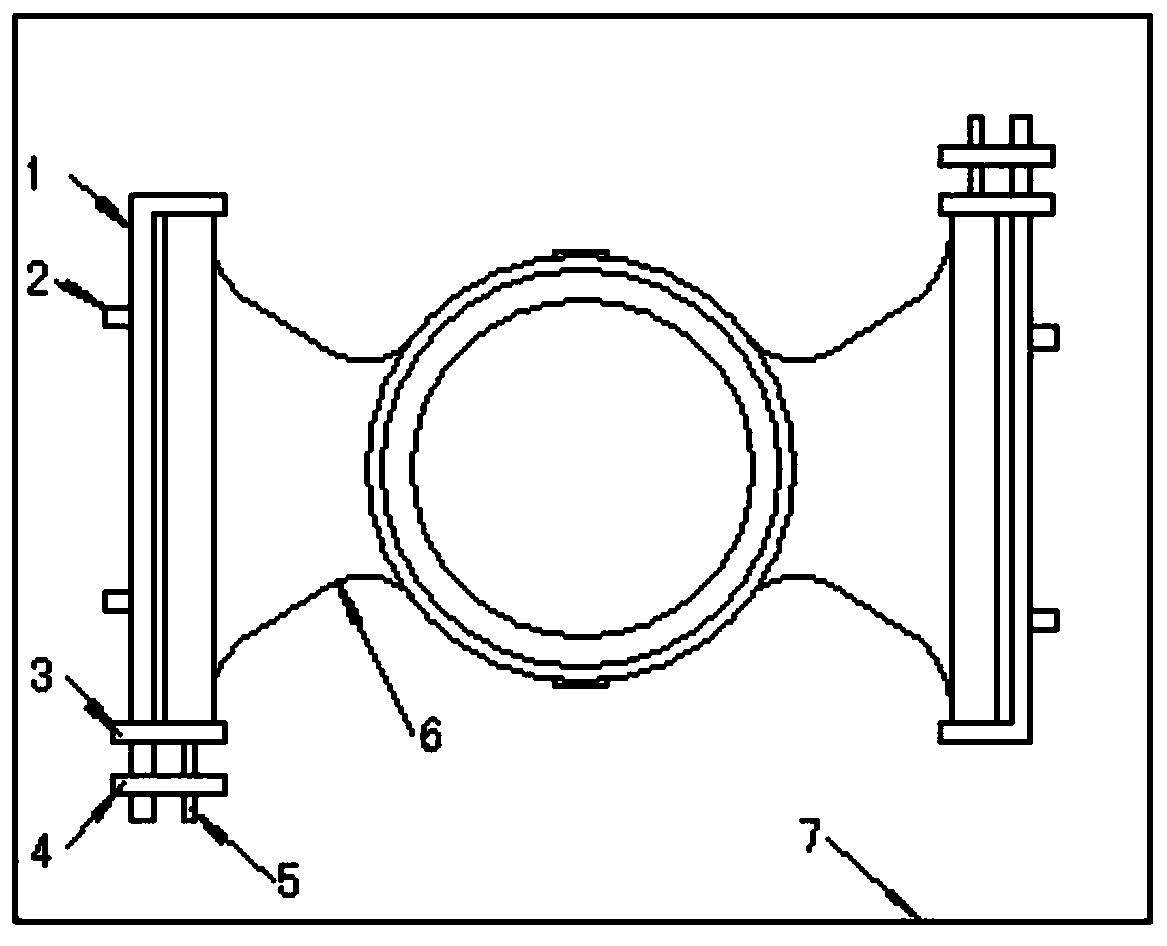

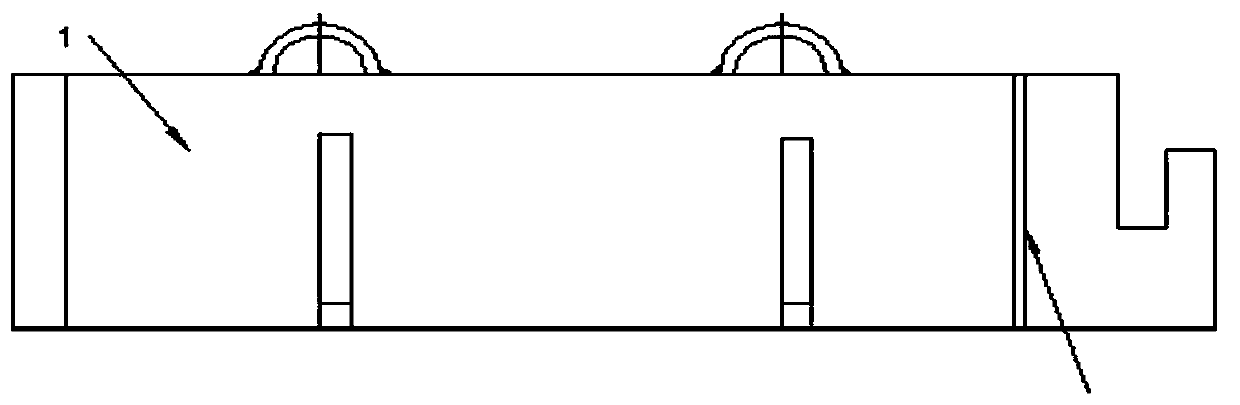

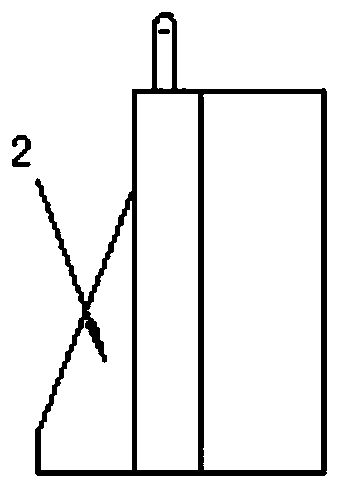

[0016] A kind of large-scale low-speed marine diesel engine crosshead slider white metal casting method of the present invention (see Figure 1-7 ), is first set to form a combined cavity. The combined cavity includes a tire plate (1), a support plate (2), a baffle plate (3), a stopper (4), a fastening rod (5), and the support plate (2) is integrated with the tire plate (1) structure, the baffle plate (3) and the block (4) are installed and positioned through the tire plate (1), and then together with the crosshead slider (6) and the casting platform (7), through the external force of the fastening rod (5), a Combined cavity for casting. That is, the crosshead slider (6) is placed on the casting platform (7), and the front of the crosshead slider is vertical on the casting platform (7); the L-shaped tire plate (1 ) is also placed on the casting platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com