Pump truck first arm pin shaft press-fitting method and press-fitting platform

A shaft press-fitting and assembly platform technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, reduce labor intensity, realize semi-automatic operation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

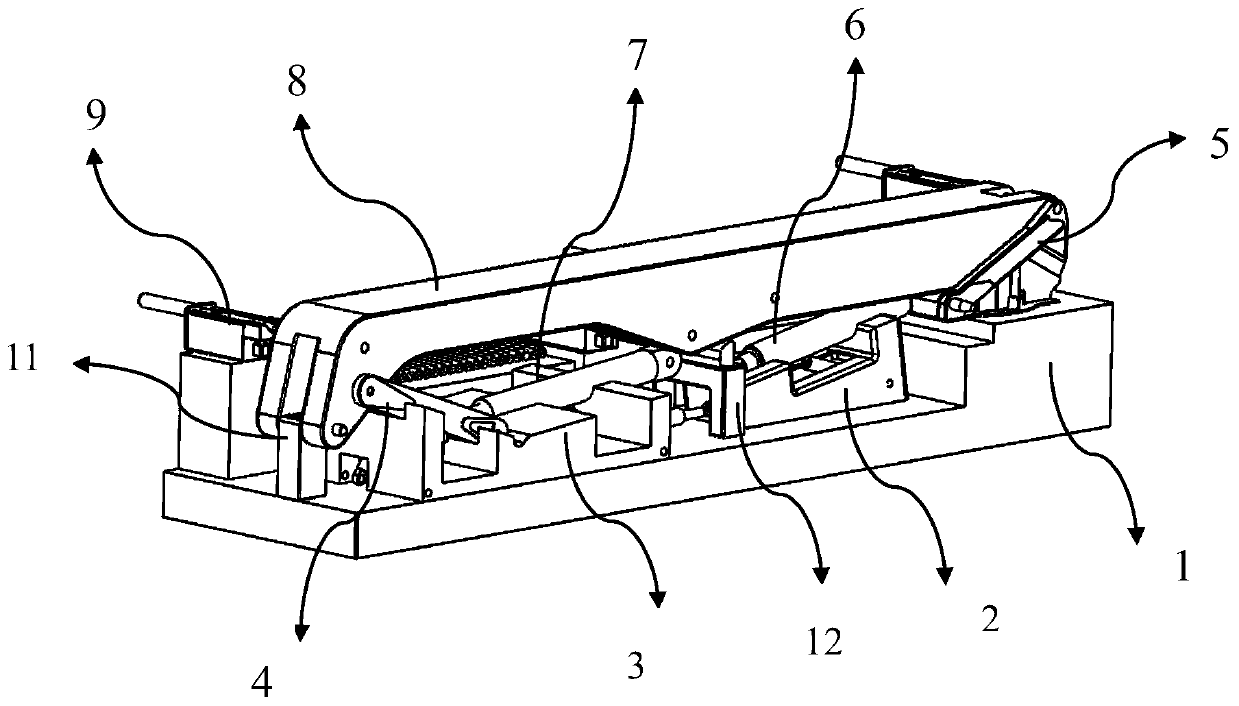

[0048] The purpose of the present invention is to provide a set of pump truck arm pin press-fitting method and press-fitting platform, the key steps of its press-fitting method are as follows:

[0049] 1) Place the turntable 5 on the designated position on the assembly platform 1, and use the shaft hole for positioning;

[0050] 2) Place the one-arm oil cylinder 6 at the designated position on the one-arm oil cylinder press-fitting mechanism 2, and use the side for positioning;

[0051]3) The push-pull mechanism 21 on the one-arm oil cylinder press-fitting mechanism 2 pushes the one-arm oil cylinder press-fit mechanism 2 and the one-arm oil cylinder 6 on it forward, so that the one-arm oil cylinder 6 is placed on the one-arm oil cylinder The barrel pin hole 61 is aligned with the turntable oil cylinder pin hole 51 on the turntable 5;

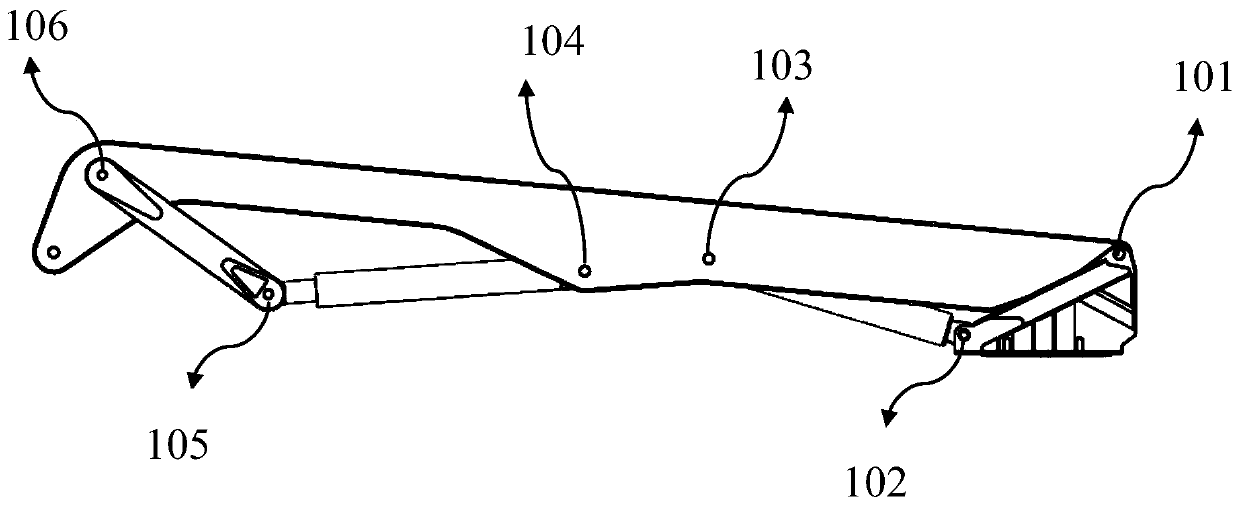

[0052] 4) The pin shaft mechanism 9 press-fits the No. II pin shaft 102 into place;

[0053] 5) Place the connecting rod 4 at the designated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com