Prefabricated assembly type self-supporting steel pipe scaffold system

A prefabricated assembly and scaffolding technology, applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of easy deformation and instability, insufficient self-supporting height, low free height of double-row scaffolding, etc., to achieve strong resistance to overturning and deformation, Simple erection and improved anti-rotational stiffness variation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

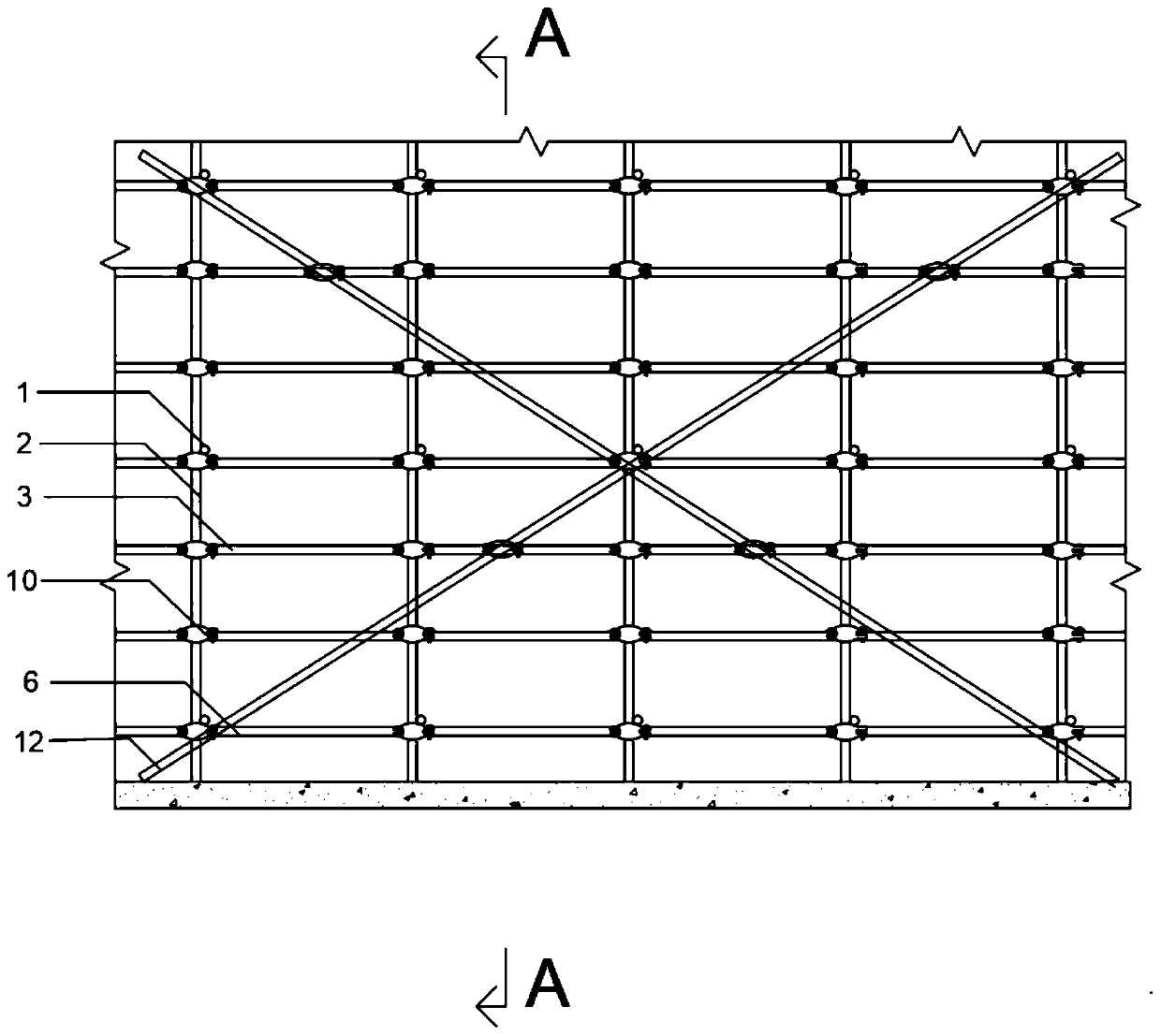

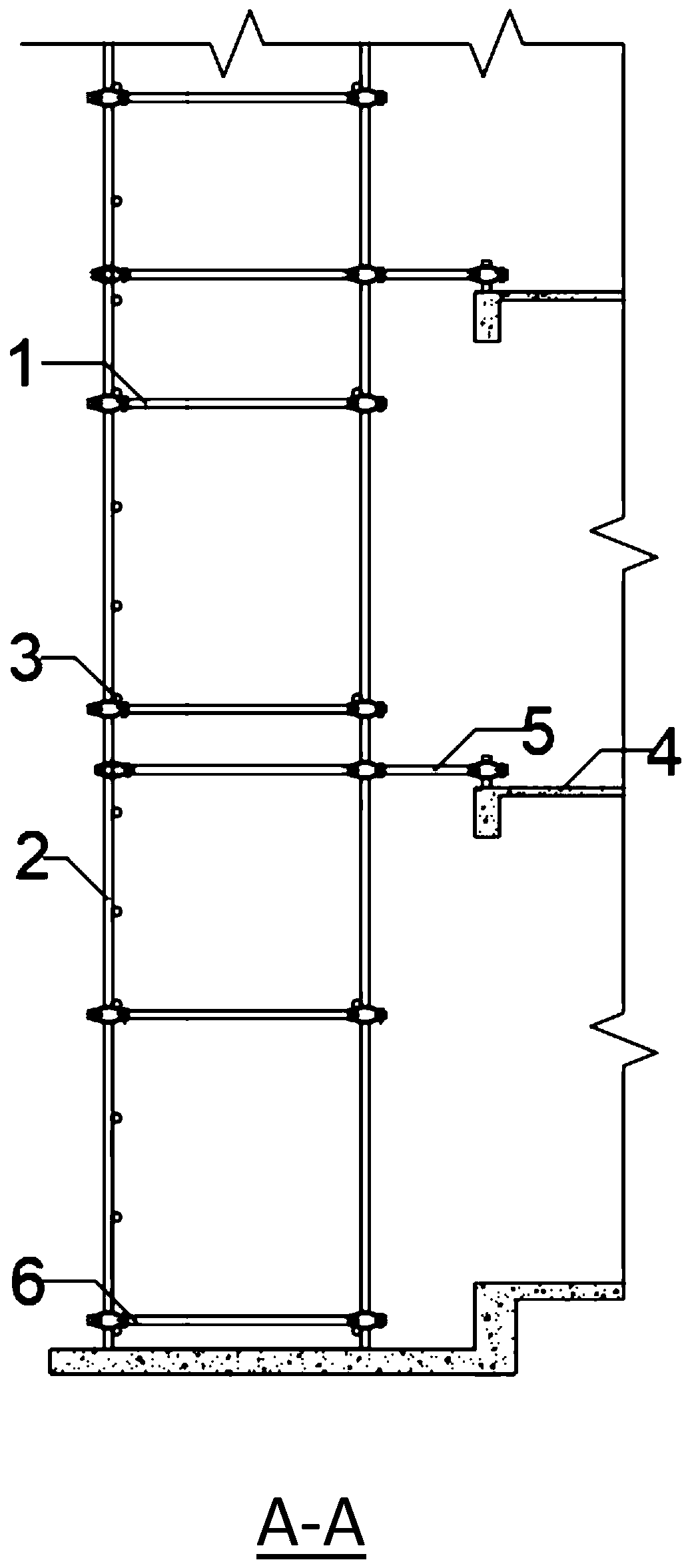

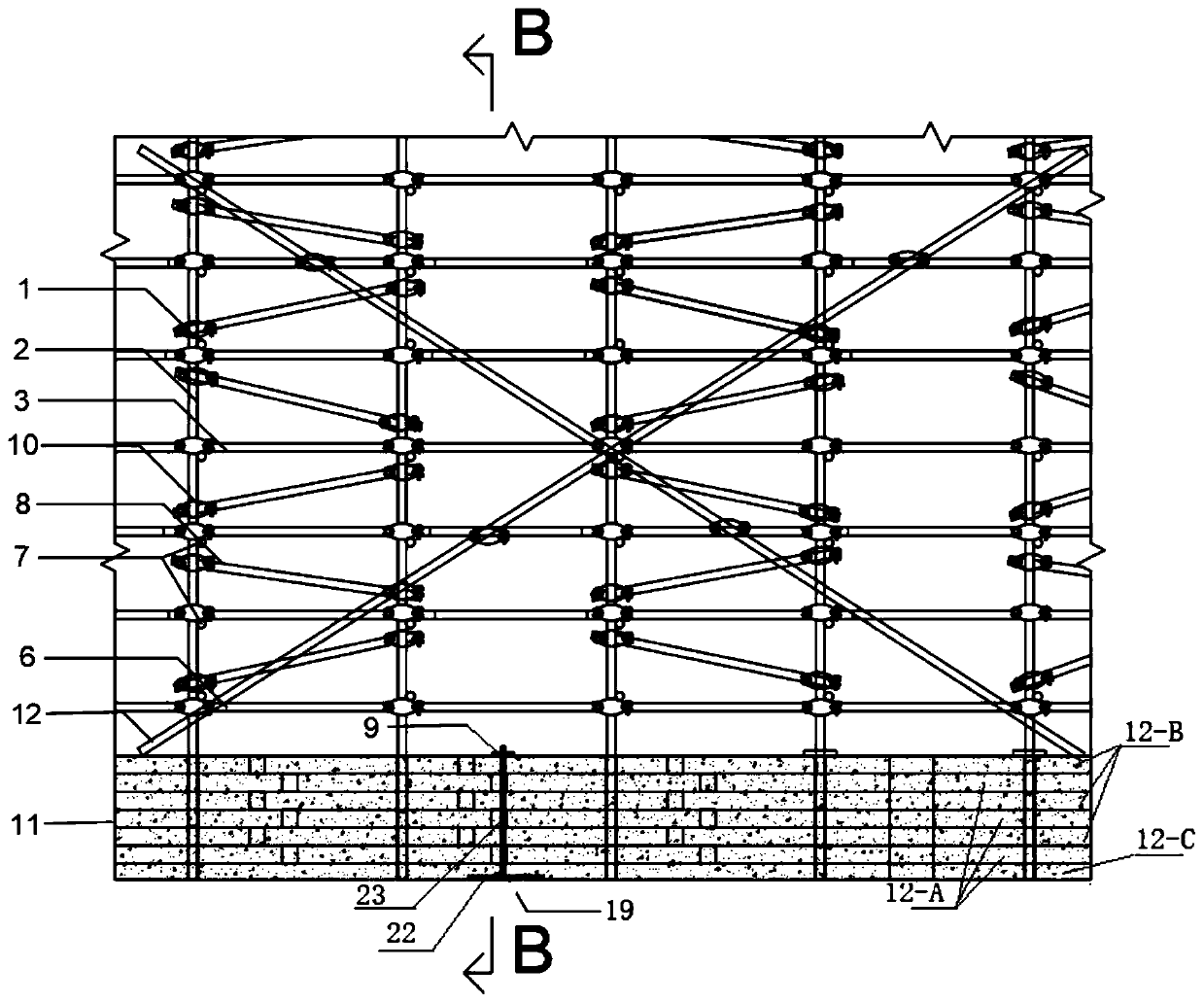

[0035] like image 3 , a self-supporting steel pipe scaffolding system that can be assembled, including prefabricated base unit 11 and lattice column-type vertical pole unit. like Image 6 and Figure 5 , the prefabricated assembly base unit 11 includes a prefabricated base plate 12-C, a prefabricated A plate 12-A, a prefabricated B plate 12-B, a prefabricated A plate 12-A and a prefabricated B plate 12-B each having two rows and multiple rows of through holes 13 The prefabricated bottom plate 12-C is alternately stacked from bottom to top, and the adjacent surfaces between the prefabricated bottom plate 12-C, the prefabricated A plate 12-A, and the prefabricated B pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com