Blasting vibration measurement method for excavating plant

A blasting vibration and open-air technology, which is applied in measuring devices, radio wave measuring systems, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as difficult alignment of blasting centers, difficult alignment, and poor accuracy of blasting vibration measurement points, etc. problem, to achieve the effect of improving accuracy, overcoming inaccurate position, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

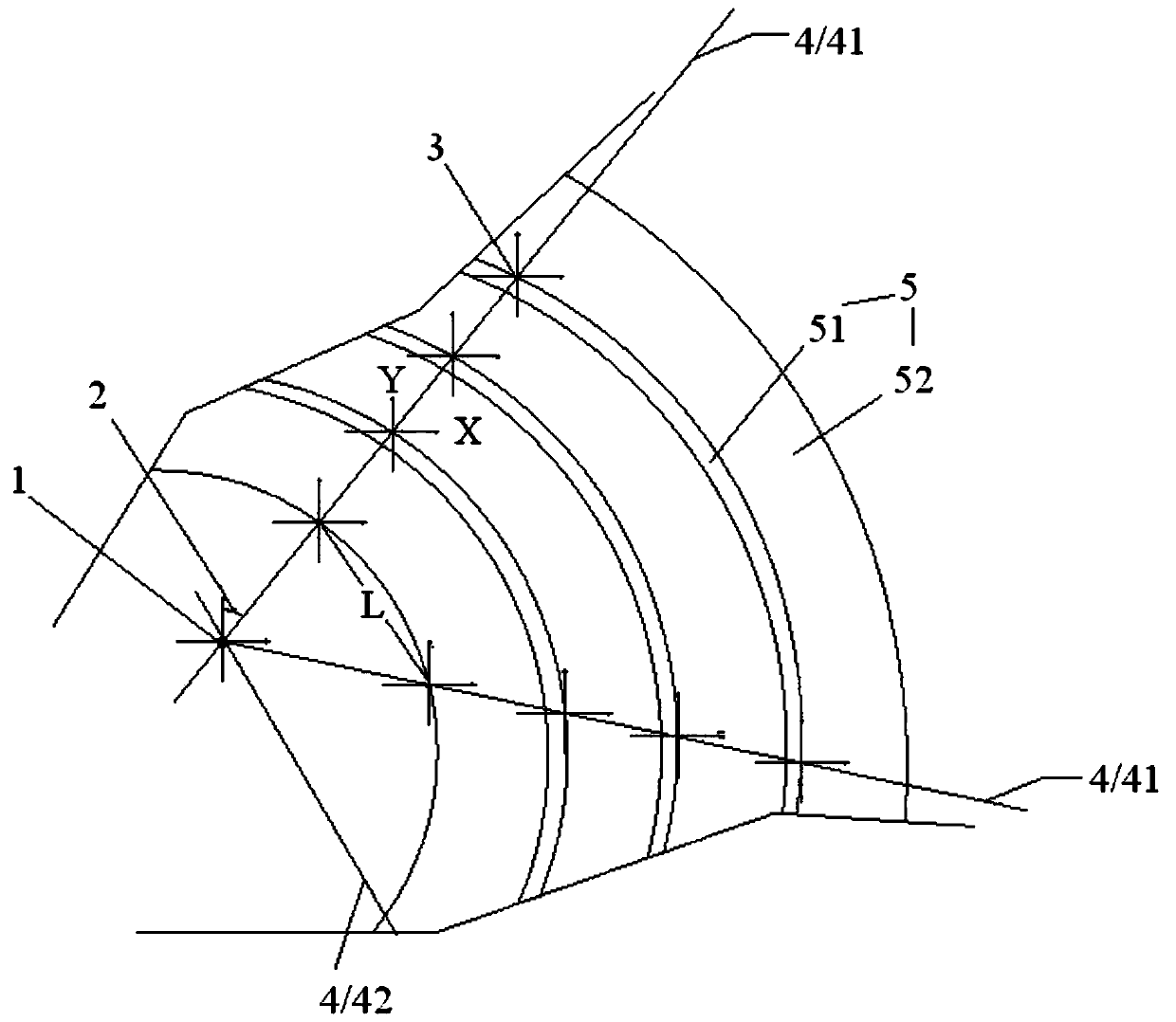

[0032] by figure 1 As an example, an open pit blasting vibration measurement method includes the following steps:

[0033] 1) Determine the position of the blasting center 1 in the central area of the stope. The blasting center is generally designed by the blasting operator according to the production plan and the stope situation. Mark the position of the center; carry out on-site investigation on the slope 5 of the open pit to understand the topography, geology, hydrology and mining conditions of the slope, and record the bedrock distribution on the slope; based on the location of the blasting center and the bedrock According to the distribution situation, the line in the open-pit stope with many bedrock masses and located close to the slope platform 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com