Combined longitudinal axial flow threshing and separating device and method and corn kernel harvester

A threshing separation and combined technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of reducing the broken rate, corn kernel damage, and increasing the broken rate of the kernel, so as to reduce the harvest loss and improve the removal rate. , the effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

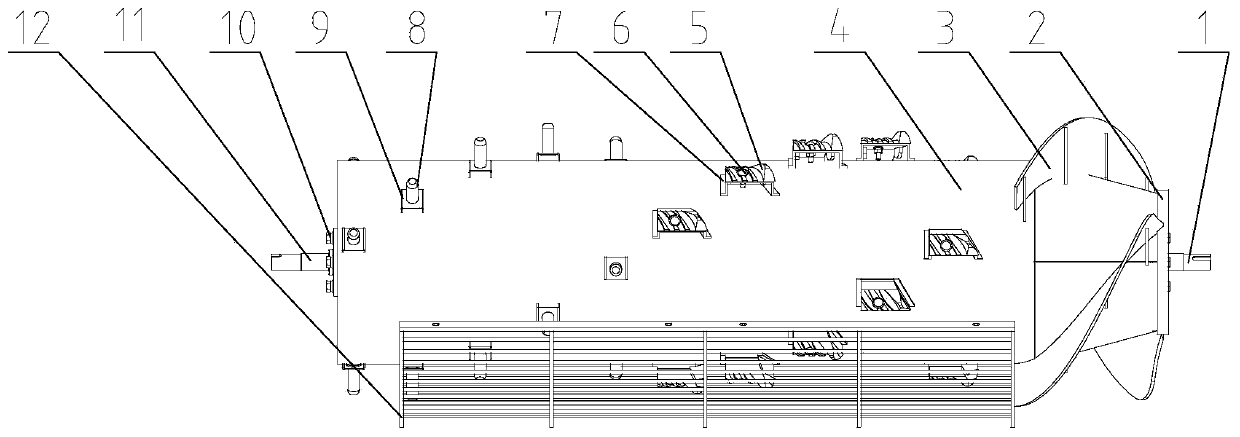

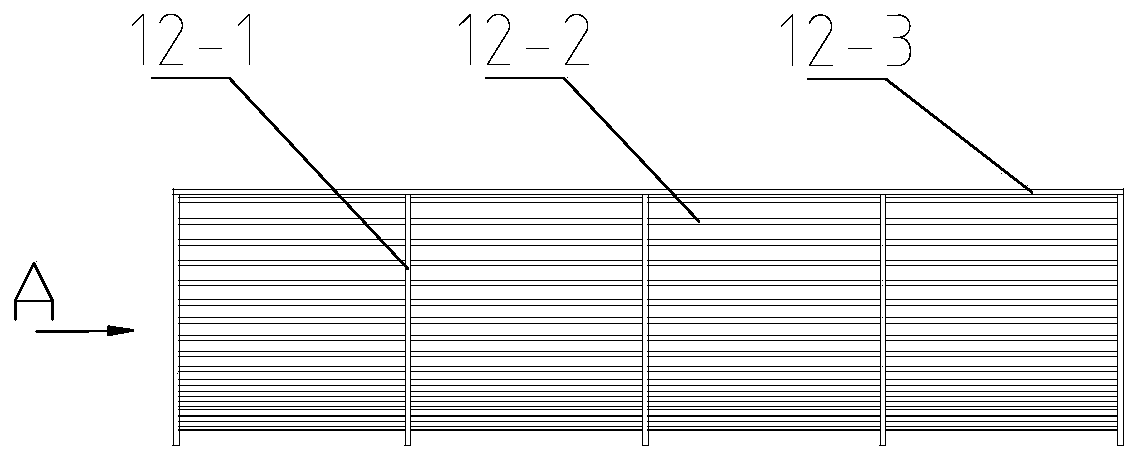

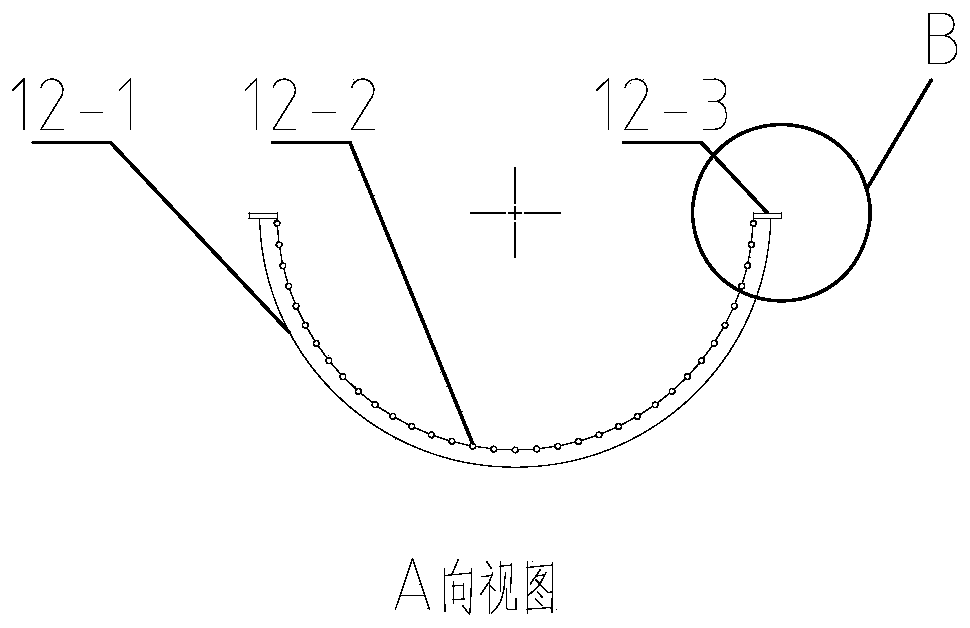

[0036] Attached below Figure 1-Figure 5 The present invention is described in detail, specifically, the structure is as follows:

[0037] This embodiment provides a combined longitudinal axial flow threshing and separation device, including a drum body 4, a spiral blade 3, a front half-shaft head 1, a rear half-shaft head 11, a threshing concave plate 12, a grain bar block 5 and a threshing spike 8 , the front end of the drum body 4 (taking the feeding direction as a reference) is equipped with a screw blade 3 and a front half shaft head 1, and the rear end of the drum body 4 is installed with a rear half shaft head 11, and the power of the drum body 4 is provided by the front half shaft head 1 .

[0038] Specifically, the front end of the drum body 4 has a bell mouth 13, and the end of the bell mouth 13 is fixed with a retaining ring 2. In this embodiment, the retaining ring 2 and the bell mouth of the drum body 4 are welded together to prevent the shaft head from being ent...

Embodiment 2

[0047] This embodiment provides a corn grain harvester, including the combined longitudinal axial flow threshing and separation device described in Embodiment 1. The combined longitudinal axis threshing and separation device is connected to a driving device, and the driving device is an existing corn grain harvester. There is a structure, so I won't go into details here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com