A kind of foam fire extinguishing system and fire extinguishing method

A foam fire extinguishing and foam liquid technology, applied in the field of fire extinguishing, can solve the problems of affecting the fire extinguishing efficiency of the compressed air foam fire extinguishing system, the low mixing efficiency of compressed air and foam mixture, and the long mixing time of foam liquid and water, so as to improve the fire extinguishing effect , improve combat capabilities, and suppress the effects of enhanced capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

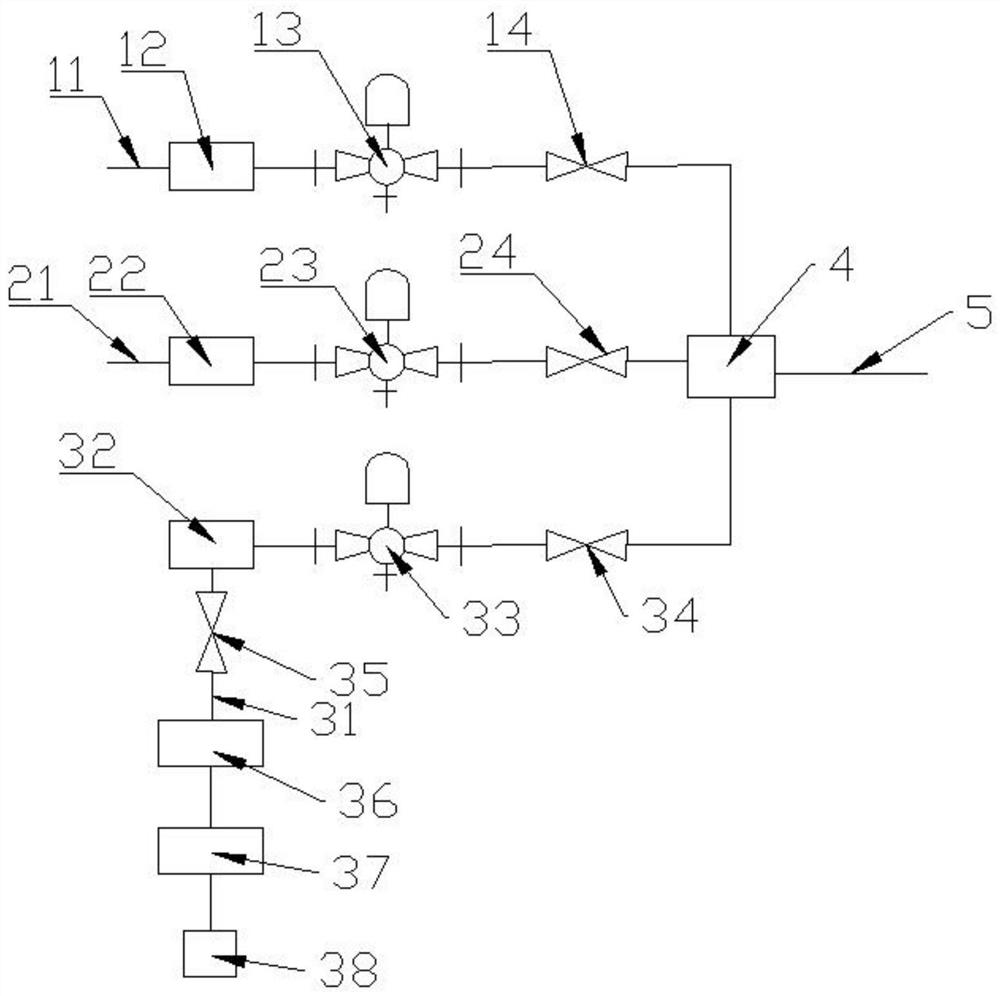

[0035] Such as figure 1 As shown, the foam fire extinguishing system of the present invention comprises a fire-fighting water source, a fire-fighting water delivery pipe 11, a foam liquid storage tank, a foam liquid delivery pipe 21, a nitrogen storage tank 36, a nitrogen delivery pipe 31, a mixer 4 and a mixed liquid delivery pipe 5. The fire water source can be a fire hydrant or a fire truck.

[0036] The input end of the fire-fighting water delivery pipe 11 is communicated with the fire-fighting water source, and the output end is communicated with the mixer 4; the fire-fighting water delivery pipe 11 is provided with a liquid flowmeter-12, a regulating valve-13, and a one-way valve-14 in sequence; the liquid flowmeter One 12 is used to detect the flow of water; the regulating valve one 13 is used to adjust the size of the water flow, and what is selected here is a proportional flow valve; one-way valve one 14 is used to prevent the fire water from flowing backward into the...

Embodiment 2

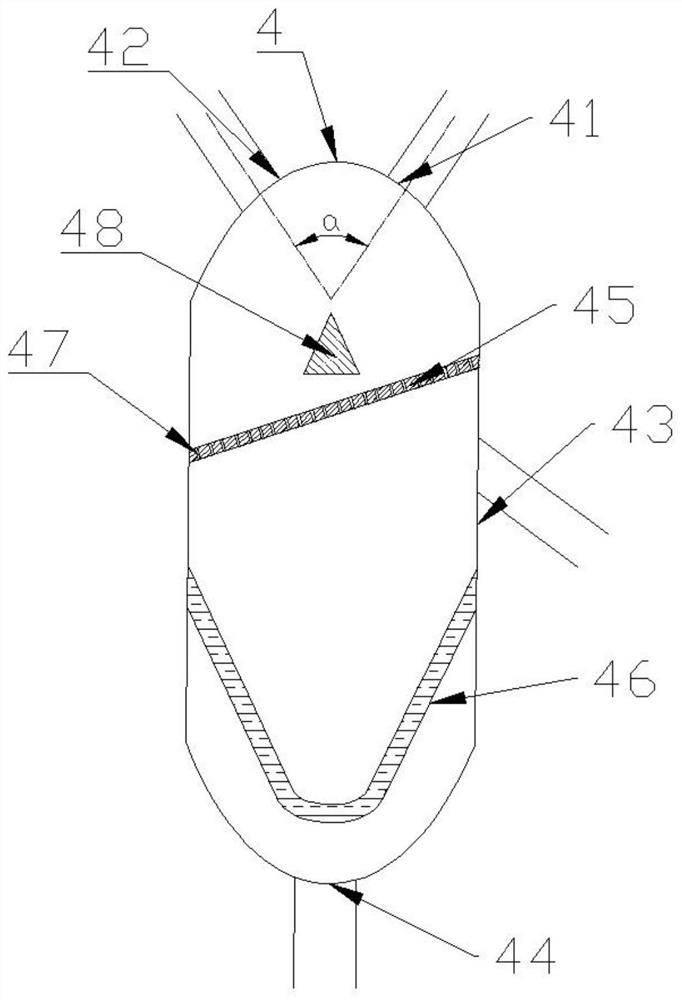

[0042] Such as figure 2As shown, the present embodiment improves the structure of the mixer 4 on the basis of the embodiment 1, as follows.

[0043] Mixer 4 is provided with fire-fighting water inlet 41, foam liquid inlet 42, nitrogen gas inlet 43 and foam liquid outlet 44; Connected, the fire water inlet 41 and the foam liquid inlet 42 are located at the top of the mixer 4, and the fire water inlet 41 and the foam liquid inlet 42 are arranged at an angle; the nitrogen gas inlet 43 communicates with the output end of the nitrogen delivery pipe 31, and the nitrogen gas inlet 43 is located below the fire-fighting water inlet 41 and the foam liquid inlet 42, and the nitrogen delivery pipe 31 is connected to the mixer 4 obliquely; Nitrogen gas flows upward while the foam liquid flows downwards, thereby making the fire-fighting water and foam liquid mix with nitrogen more evenly; The cross flow makes it able to generate vortex with good mixing effect.

[0044] The mixer 4 is pr...

Embodiment 3

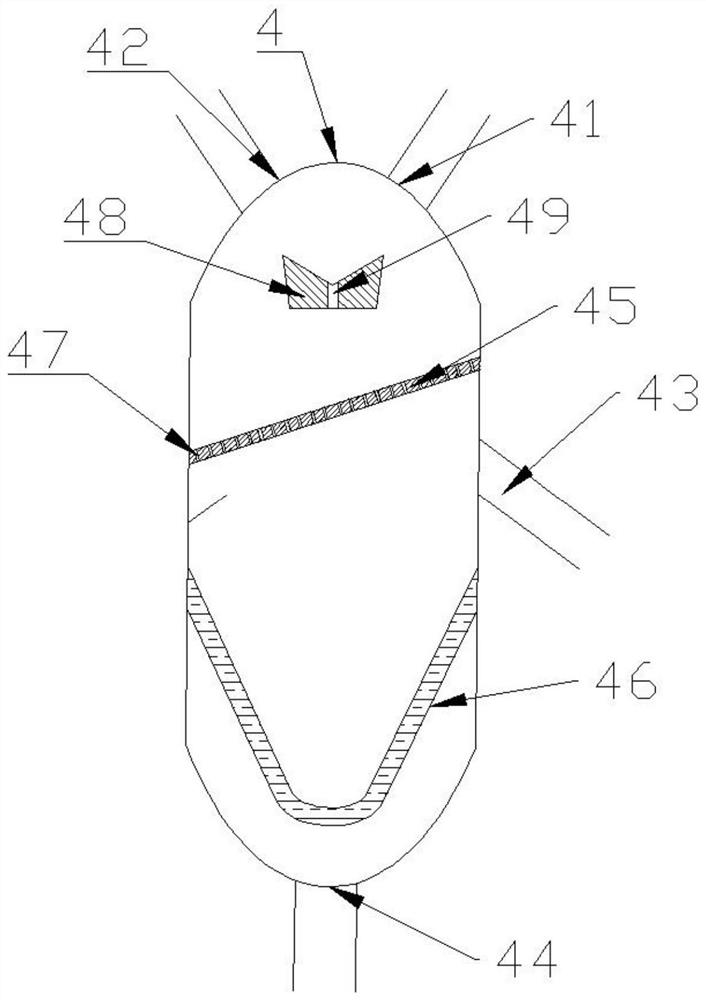

[0049] Such as figure 2 As shown, the present embodiment improves the structure of the mixer 4 on the basis of the embodiment 2, as follows.

[0050] The mixer 4 is also provided with a disperser 48 located in the axial direction of the mixer 4 . The disperser 48 is provided with a conical structure, and the conical top of the conical structure faces the top of the mixer 4 . In this embodiment, the disperser 48 is provided with a conical top, such as figure 2 As shown, the conical apex faces vertically towards the top of the mixer 4 . The fire-fighting water inlet 41 and the foam liquid inlet 42 are symmetrically arranged on the top of the mixer 4 with the axial direction of the mixer 4 being symmetrical. The fire-fighting water delivery pipe 11 and the foam solution delivery pipe 21 form an included angle of a=30-75°; the diffuser 48 is located below the intersection of the fire-fighting water delivery pipe 11 and the extension line of the foam solution delivery pipe 21. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com