Condenser return-type forming machine

A molding machine and condenser technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low work intensity of operators, low production efficiency, limited scope of application, high manufacturing cost, etc., and achieve improved application range, reduced work intensity, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

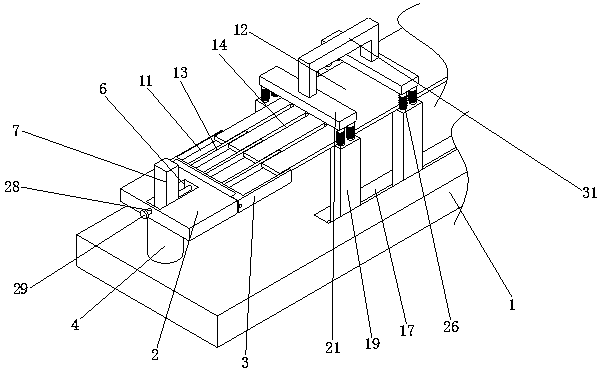

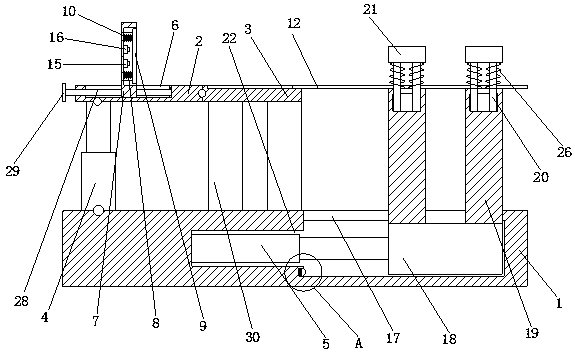

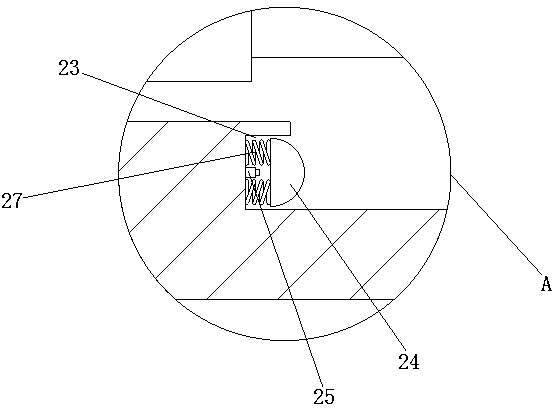

[0021] see Figure 1-3 , the present invention provides a technical solution: a condenser back molding machine, including a base 1, the bottom of the base 1 is hinged with a first cylinder 4, the piston rod of the first cylinder 4 is hinged with a first plate 2, the first The cylinder 4 drives the first plate body 2 to move upwards to bend the condensation pipe. The inside of the first plate body 2 is provided with a guide groove 6, and the inside of the guide groove 6 is slidingly connected to the limit rod 7, which can limit the bending length, one side of the first board 2 is hinged with a second board 3, the inside of the second board 3 is provided with a second groove 11, and the inside of the second groove 11 is slidably connected with a carrier board 12, through The second groove 11 guides and limits the stroke of the carrier plate 12, the limit rod 7 is provided with a first groove 8 on the side close to the second plate body 3, and the inside of the first groove 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com