Jackscrew reciprocating motion mechanism

A technology of reciprocating movement and top wire, which is applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve the problem of no operable space, etc., and achieve the effect of simple structure and small space requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

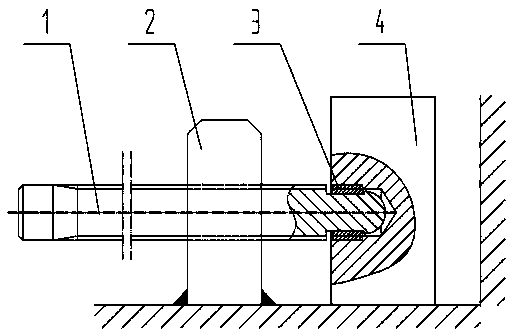

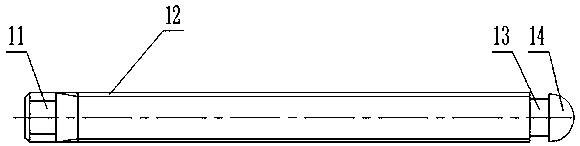

[0017] like Figure 1-Figure 4 As shown, a jackscrew reciprocating movement mechanism of the present invention comprises jackscrew 1, jackscrew plate 2, clamping plate 3 and workpiece 4, jackscrew 1 passes jackscrew plate 2, jackscrew plate 2 is fixed in a position, jackscrew Wire 1 is threadedly connected with top wire plate 2, and the end of top wire 1 is provided with coaxially connected journal 13 and hemispherical end 14. Hinged, clamping plate 3 is threadedly connected with workpiece 4, jackscrew 1 can advance and retreat in jackscrew plate 2 under rotation, thereby drives workpiece 4 to realize reciprocating motion.

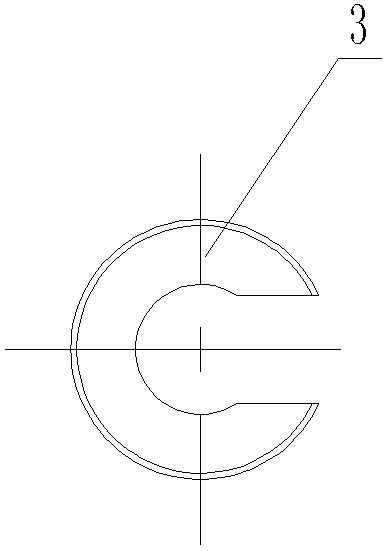

[0018] The clamping plate 3 is a circular plate with a notch, and the periphery of the circular plate is processed with external threads. The clamping plate 3 is sleeved on the journal 13. The workpiece 4 is provided with a blind hole, and the clamping plate 3 is connected to the blind hole thread.

[0019] The head end of the top wire 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com