Prefabricated concrete pipe piece with internal light filling body and prefabricating method

A technology of filling body and concrete, which is applied in earthwork drilling, manufacturing tools, wellbore lining, etc. It can solve the problems of increasing tunnel leakage, affecting the durability of segment structure, and the self-heaviness of segments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The invention provides a prefabricated concrete segment with built-in lightweight filler and a prefabrication method. The prefabricated concrete segment with built-in lightweight filler can be applied to underground projects constructed by prefabricated assembly methods, including but not limited to shield tunnels, assembled Ring-type pipe jacking tunnels, drilling and blasting prefabricated and assembled secondary linings, underground pipe galleries, prefabricated and assembled underground projects, underground complexes, etc.

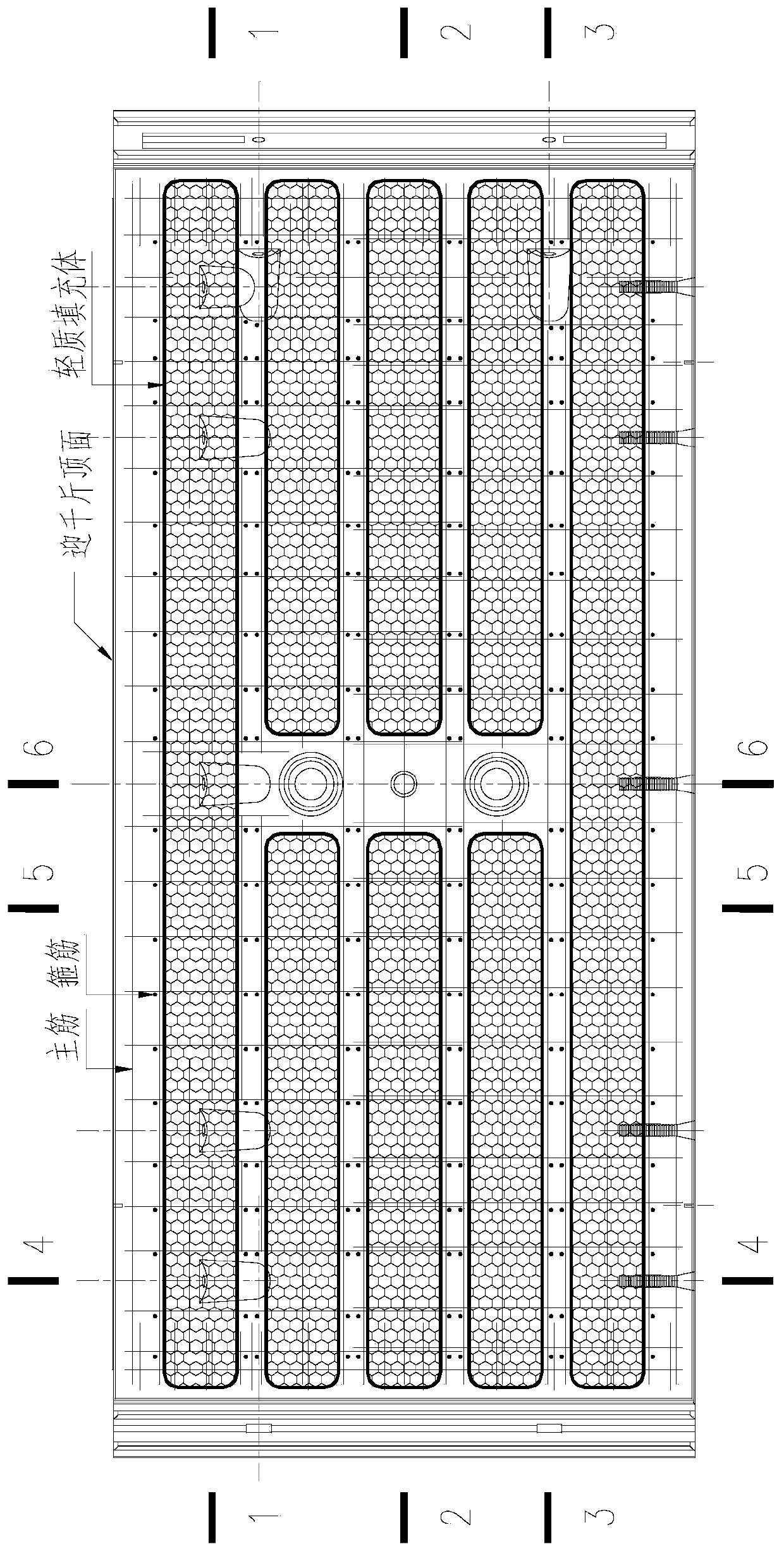

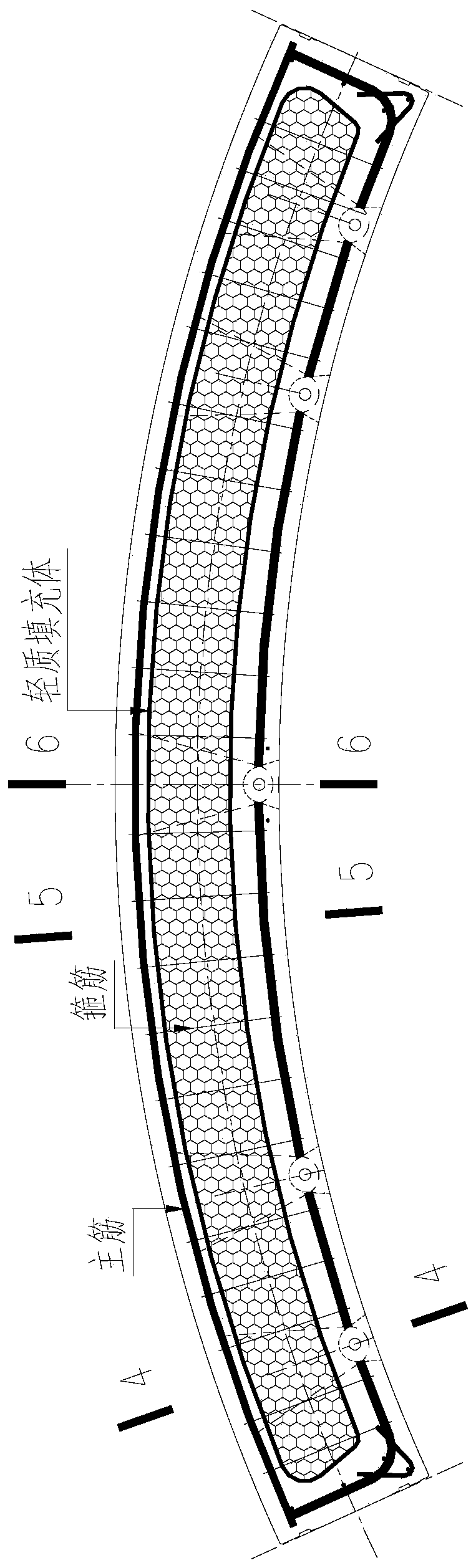

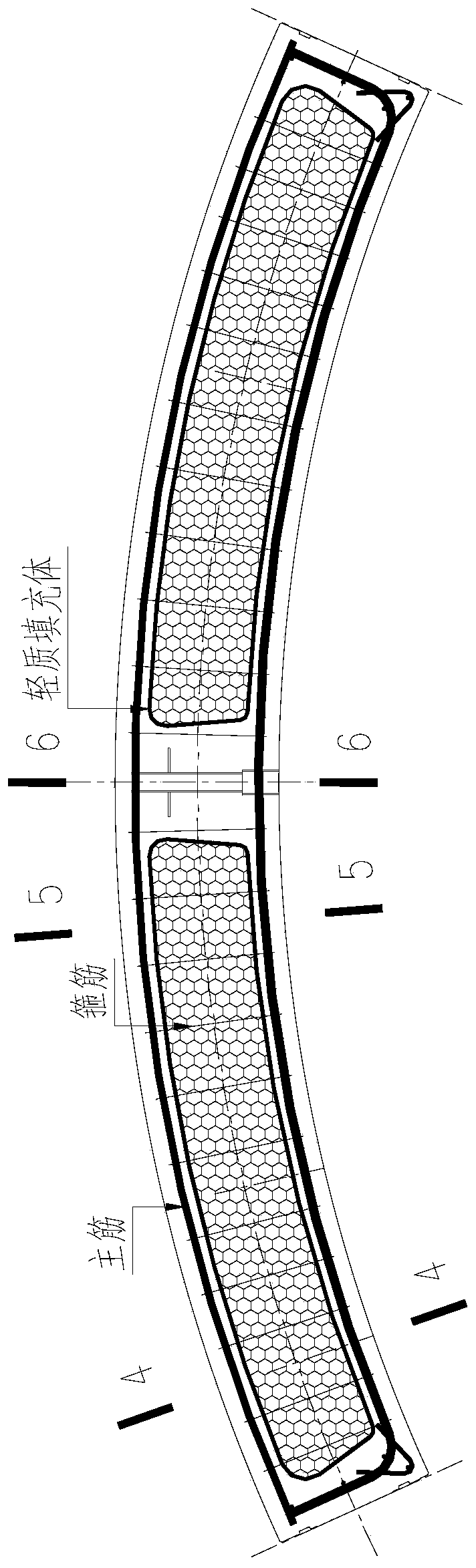

[0032] The structure of the prefabricated built-in lightweight concrete segment is as follows: Figure 1-7 As shown, the prefabricated concrete segment with built-in lightweight filler includes a segment skeleton, a lightweight filler arranged in the segment skeleton, and a segment body formed by pouring concrete. The lightweight filler is carried out through the hook on the segment skeleton. fixed.

[0033] The prefabricated built-in lightwei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com