Powder material transport compartment

A carriage and powder technology, which is applied in the field of powder material transportation carriages, can solve the problems of cost, labor and time, and achieve the effect of increasing speed, saving labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

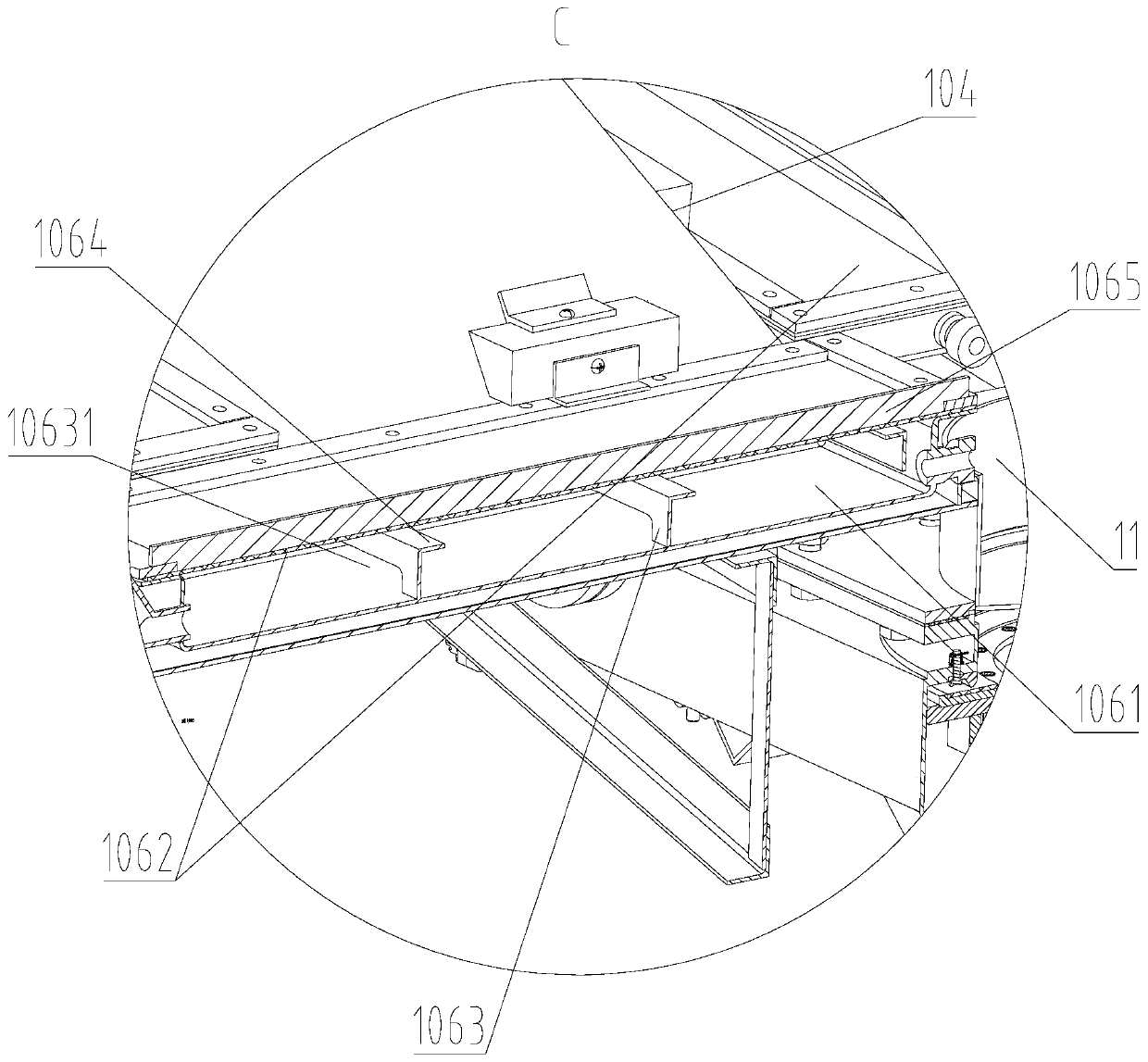

[0036] As a specific implementation of the powder material transportation compartment provided by the present invention, please refer to figure 2 The opening and closing assembly includes a first opening and closing plate 1031 and a sealing ring 1032 fixed on the inner surface of the first opening and closing plate 1031. The sealing ring 1032 is used to close the gap between the first opening and closing plate 1031 and the feed port 102. , to ensure the sealing between the first opening and closing plate 1031 and the feeding port 102 , and prevent liquid from entering the storage chamber 101 .

[0037] As a specific implementation of the powder material transportation compartment provided by the present invention, please refer to figure 2 , the first opening and closing mechanism includes a first opening and closing rod 1033 , a first threaded rod 1034 and a first compression nut 1035 . The first opening and closing rod 1033 is arranged on the top of the first opening and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com