Wind driven automatic-proportioning concrete sprayer

A technology of concrete spraying machine and automatic proportioning, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of many supporting power equipment, high cost, waste of raw materials, etc., and achieve the improvement of support quality and work efficiency, The effect of preventing the imbalance of raw material ratio and improving the quality of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

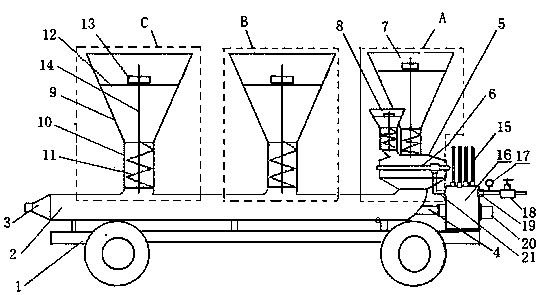

[0019] Such as figure 1 Shown, a kind of concrete injection machine of automatic proportioning driven by wind power, it comprises walking frame 1 and is installed on the walking frame and is used for the horizontal pipe 2 of concrete material proportioning and conveying; The front end is provided with a tapered pipe 3, and the tail is provided with a pressure air pipe interface 4, and a proportional conveying device connected with it is arranged on the pipe body; the proportional conveying device is sequentially from the back to the front: the cement slurry proportional conveying device A, the stone proportional conveying device Conveying device C and sand ratio conveying device B; wherein the structure of grout ratio conveying device A is to include a cement slurry mixing bucket 5, the bottom of the cement slurry mixing bucket 5 communicates with the horizontal pipe 2, on the cement slurry mixing bucket 5 There is a circle of surrounding water pipes 6, and a plurality of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com