Solid-liquid phase change heat storage device with built-in movable heat exchanger and using method

A technology for heat storage devices and heat exchangers, which is applied in the types of heat exchangers, indirect heat exchangers, heat storage equipment, etc. It can solve the problem of uneven mixing of phase-separated materials, reduce the heat storage and release performance of materials, and shorten the service life, etc. problems, achieve the effect of reducing supercooling and phase separation, simple structure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

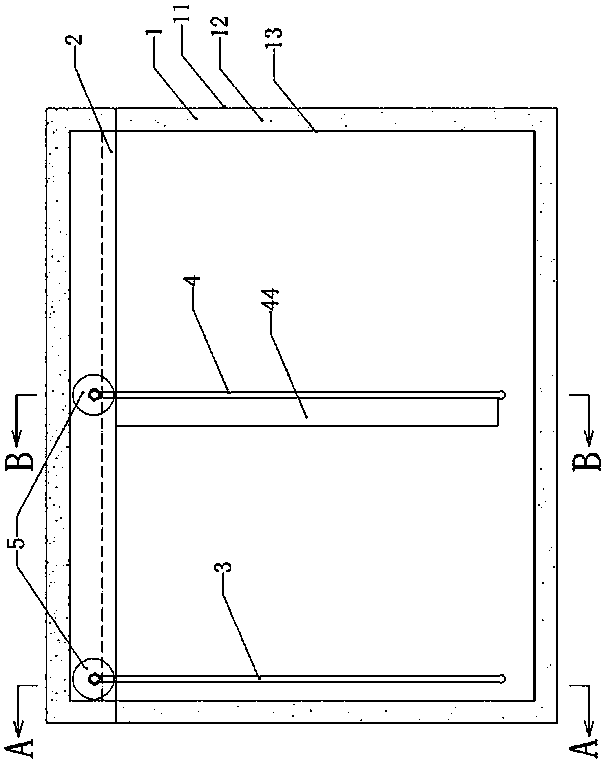

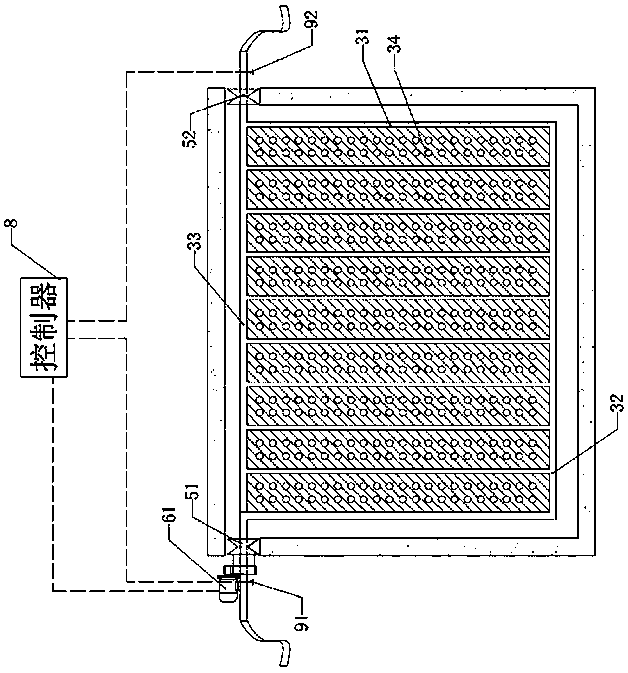

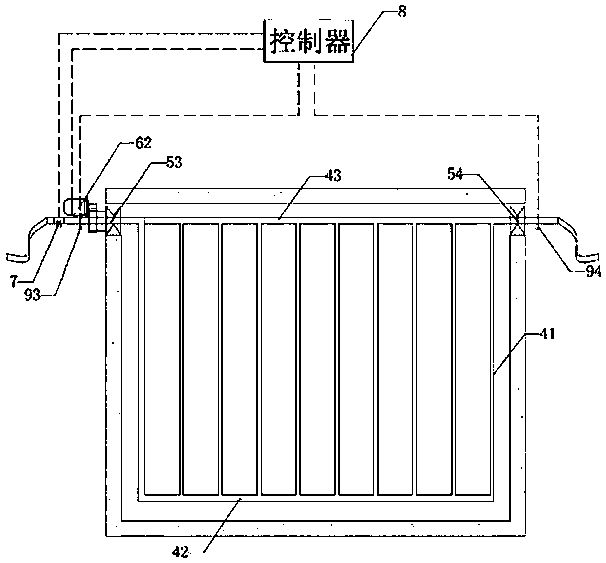

[0027] Embodiment one: if Figure 1 ~ Figure 3 As shown, the specific embodiment of the present invention is: a heat storage box 1 composed of an outer shell 11, an insulating material 12 and an inner tank 13, and an inverted V-shaped track 2 is installed on the upper ends of the left and right sides of the heat storage box 1; The device 4 is composed of a second row of pipes 41, a second upper header 43, a second lower header 42 and a heat transfer plate 44; The pipe 43 and the second lower header 42 are welded with an area of 0.05m 2 The heat transfer plate 44 is welded on the second row of pipes 41 and its direction is perpendicular to the plane of the collecting and discharging pipes; one end of the second lower header 42 stretches out of the heat storage box 1 as an inlet, and one end is sealed; the second upper header 43 One end extends out of the heat storage box 1 as an outlet, and the other end is closed; the heat absorbing heat exchanger 3 is composed of a first r...

Embodiment 2

[0031] Embodiment 2: Based on the above embodiments, in this embodiment, the first and second motors 61 and 62 are respectively installed at the outlet ends of the heat absorbing heat exchanger 3 and the heat releasing heat exchanger 4, and are connected with the second and fourth rolling bearings. 52,54 mesh.

Embodiment 3

[0032] Embodiment 3: Based on the above embodiments, solid paraffin is placed inside the heat storage box 1, and its latent heat of phase change is 189J / g, and its density is 0.00093g / mm 3 , then the program setting value of heat =10.5KJ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com