Light-reflective braided cable

A reflective and cable technology, used in cables, insulated cables, textiles and papermaking, etc., can solve the problems of not being able to play an obvious safety warning role, the earphone braided cable cannot be reflected, and the comfort of the earphone cable is reduced. Improve the preparation rate and color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

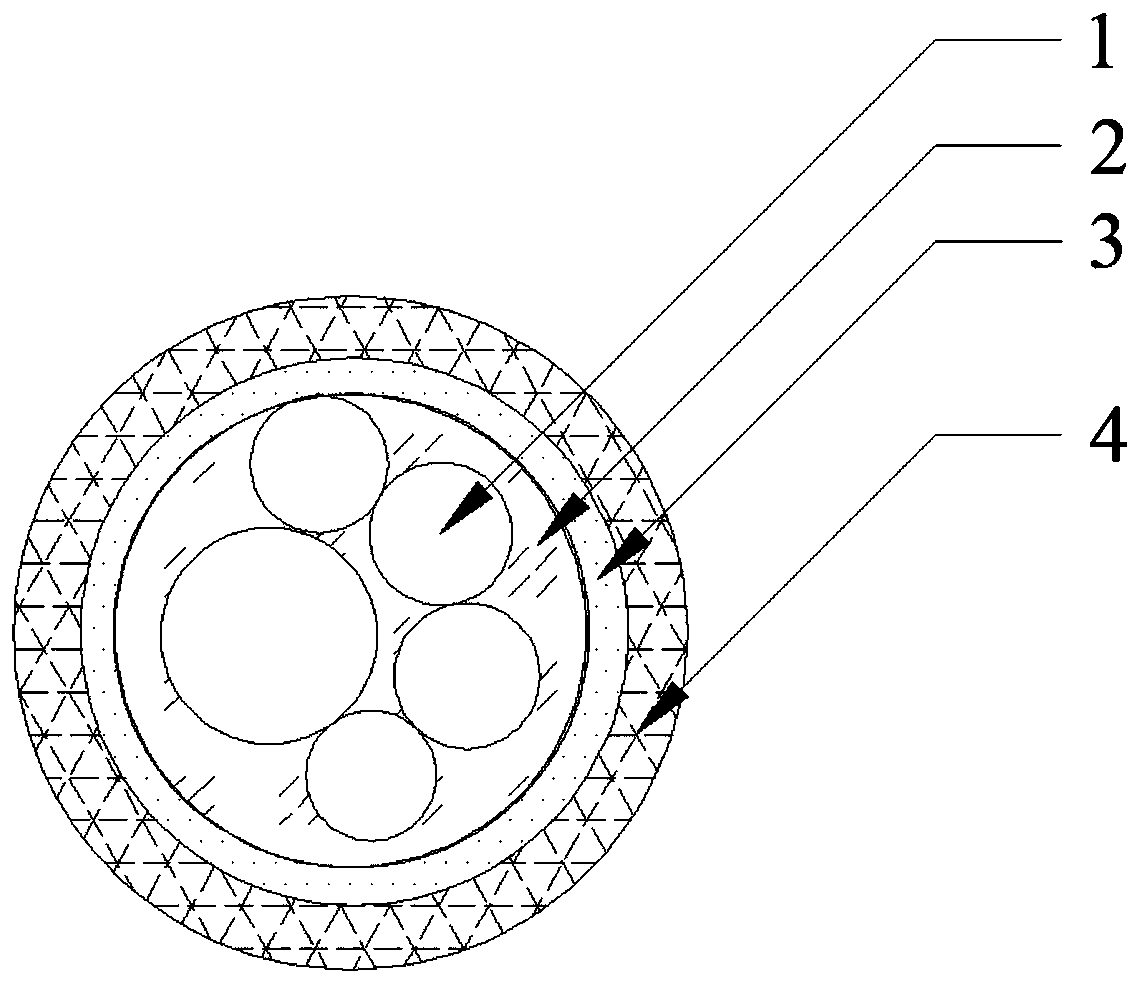

[0032] A reflective braided cable, including several conductive cables 1 with insulating layers, and also includes a flame-retardant layer 2, an insulating sheath 3, and a reflective fiber protective layer 4, and the reflective fiber protective layer 4 is made of 24 reflective fibers. The way of the horse ingot is formed by weaving 14 leftwards and 10 rightwards; the conductive cables 1 are mutually twisted and arranged in the insulating sleeve 3, and the flame retardant layer 2 is filled in the insulating sleeve 3. The reflective fiber protective layer 4 is woven on the outer surface of the insulating sheath 3 .

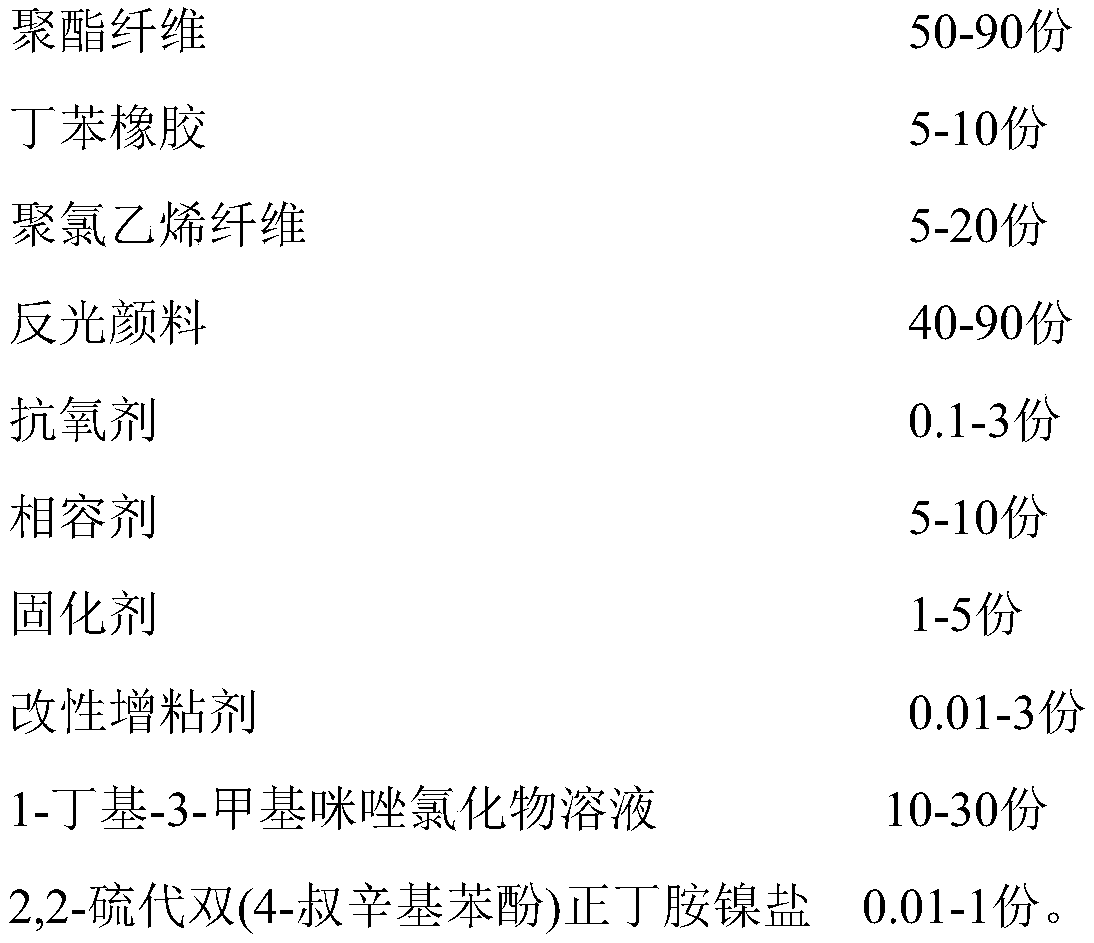

[0033] The reflective fiber includes the following raw materials in parts by weight:

[0034]

[0035] Each part of the modified tackifier includes the raw materials of the following parts by weight:

[0036]

[0037] Described modified tackifier is made by following steps:

[0038] 1) According to parts by weight, mix natural rubber, polyethylene glycol and...

Embodiment 2

[0049] A reflective braided cable, including several conductive cables 1 with insulating layers, and also includes a flame-retardant layer 2, an insulating sheath 3, and a reflective fiber protective layer 4, and the reflective fiber protective layer 4 is made of 24 reflective fibers. The way of walking around is formed by weaving 18 leftwards and 6 rightwards; the conductive cables 1 are mutually twisted and arranged in the insulating sleeve 3, and the flame retardant layer 2 is filled in the insulating sleeve 3. The reflective fiber protective layer 4 is woven on the outer surface of the insulating sheath 3 .

[0050] The reflective fiber includes the following raw materials in parts by weight:

[0051]

[0052]

[0053] Each part of the modified tackifier includes the raw materials of the following parts by weight:

[0054]

[0055] Described modified tackifier is made by following steps:

[0056] 1) Mix natural rubber, polyethylene glycol and polybutene accordin...

Embodiment 3

[0067] A reflective braided cable, including several conductive cables 1 with insulating layers, and also includes a flame-retardant layer 2, an insulating sheath 3, and a reflective fiber protective layer 4, and the reflective fiber protective layer 4 is made of 24 reflective fibers. The way of the horse ingot is formed by weaving 16 leftwards and 8 rightwards; the conductive cables 1 are twisted with each other and arranged in the insulating sleeve 3, and the flame retardant layer 2 is filled in the insulating sleeve 3. The reflective fiber protective layer 4 is woven on the outer surface of the insulating sheath 3 .

[0068] The reflective fiber includes the following raw materials in parts by weight:

[0069]

[0070] Each part of the modified tackifier includes the raw materials of the following parts by weight:

[0071]

[0072]

[0073] Described modified tackifier is made by following steps:

[0074] 1) Mix natural rubber, polyethylene glycol and polybutene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com