Dust exhauster for peanut harvester

A technology of peanut harvester and dust collector, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of high cost, cumbersome and inconvenient transformation work, inability to conveniently install and use dust reduction improvement work alone, and achieve Reduce dust pollution and facilitate dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

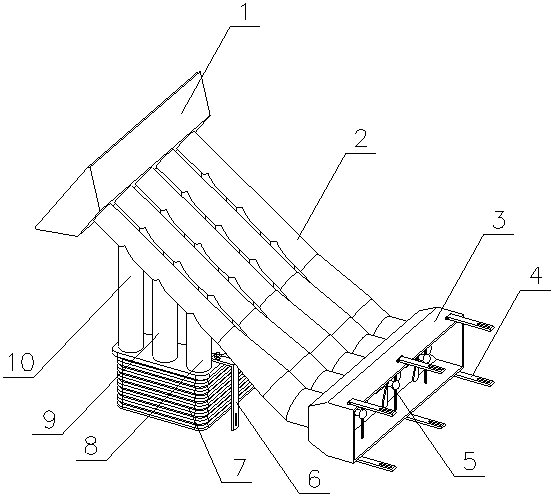

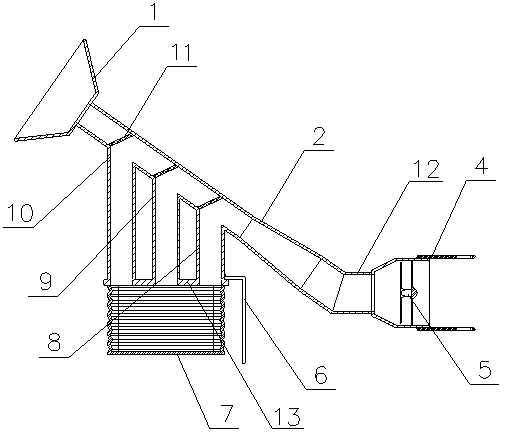

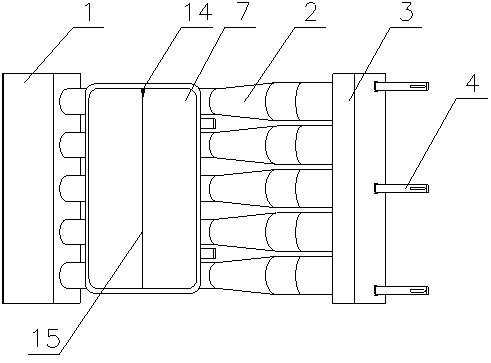

[0020] A peanut harvester dust extractor of the present invention is realized in the following way: a peanut harvester dust extractor of the present invention is composed of an exhaust cover (1), a dust reduction pipe (2), an air intake cover (3), and a connecting piece (4 ), exhaust fan (5), connecting plate (6), dust box (7), No. 1 settling pipe (8), No. 2 settling pipe (9), No. 3 settling pipe (10), dust filter (11) , dust inlet pipe (12), fixed plate (13), pull button (14) and zipper (15), one end of multiple dust inlet pipes (12) is connected with one side of the air inlet cover (3), so The other side of the air inlet hood (3) is open, a plurality of the dust inlet pipes (12) are equidistantly distributed, the dust inlet pipes (12) and the air inlet hood (3) are connected, and a plurality of dust One end of the pipe (2) is connected to the other end of the plurality of dust-falling pipes (2) in one-to-one correspondence, the plurality of dust-falling pipes (2) are paralle...

Embodiment 2

[0023] The difference between this embodiment and Example 1 is that the No. 1 settling tube (8), the No. 2 settling tube (9), and the No. 3 settling tube (10) are all bent multiple times, and the adjacent bending sections The bending direction is opposite; when in use, it can prevent the settled dust from being disturbed by the air flow and overflowing from the pipe to affect the dust removal effect.

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 is: the No. 1 settling tube (8), the No. 2 settling tube (9), and the No. 3 settling tube (10) are all spiral tubular structures; when used, the anti-settling effect can be further improved The problem of dust backflow is to prevent the settled dust from being disturbed by the air flow and overflowing from the pipe to affect the dust removal effect.

[0026] The diameter of one end of the dust fall pipe (2) is designed to be larger than the diameter of the other end, which can facilitate the gas entering the dust fall pipe (2) from one end;

[0027] The downward sloping design of the air inlet side of the dust filter (11) can make the dust fall down better and further improve the dust reduction effect;

[0028] The dust collection box (7) is designed as a corrugated box, and the dust collection box (7) can be folded and unfolded for easy storage;

[0029]One end of the connecting piece (4) is designed to be hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com