Aluminum rod welding device and welding method thereof

A technology for welding devices and aluminum rods, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as interference and cumbersome welding methods of aluminum rods, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

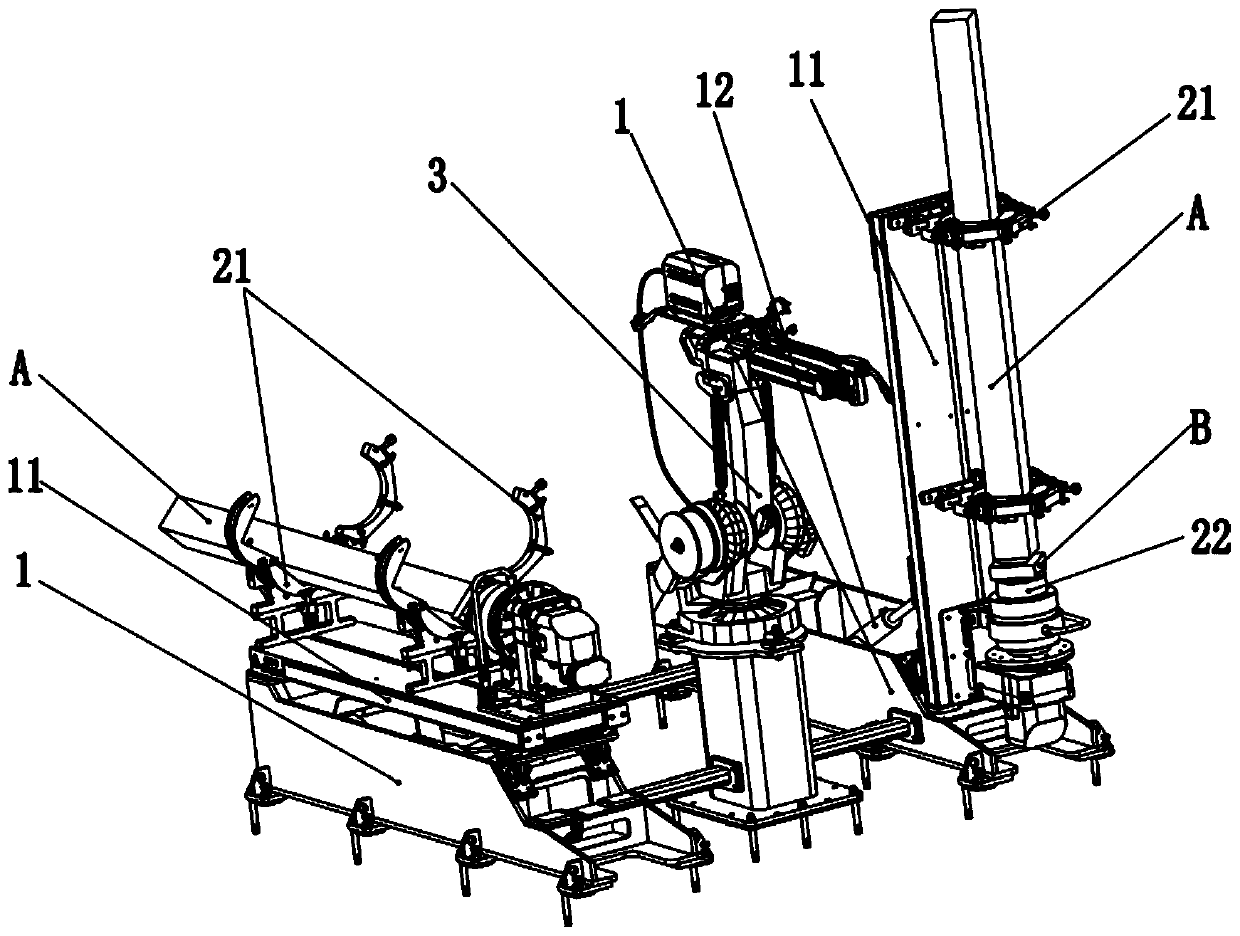

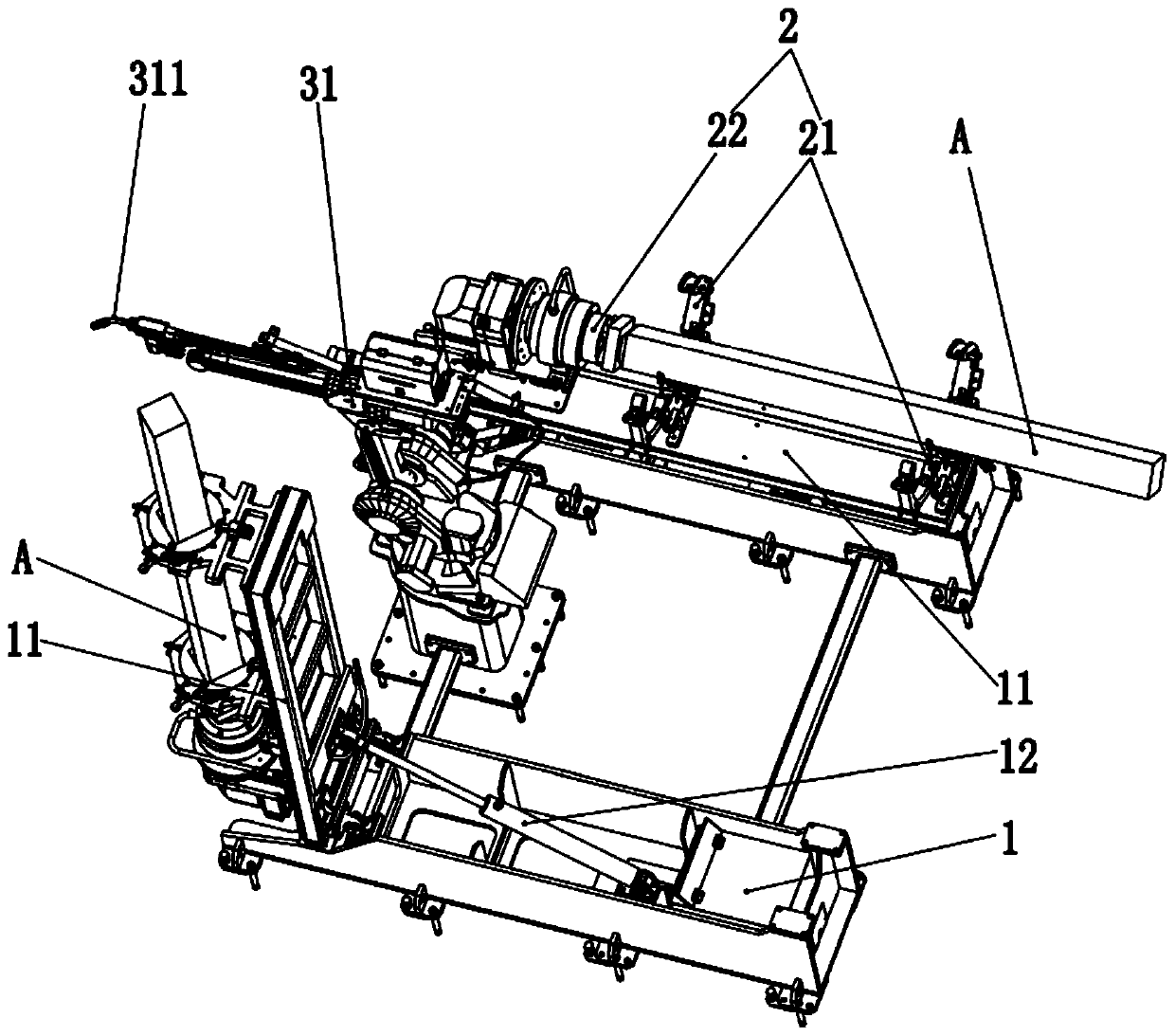

[0041] combine Figure 1 to Figure 2 , this embodiment provides an aluminum rod welding device, including a workbench 1 , a clamping mechanism 2 and a welding mechanism 3 .

[0042] There is a rotatable base 11 on the workbench 1, and the base 11 rotates from a horizontal state to a vertical state, so as to perform welding work accordingly. Wherein, when the base 11 is in a horizontal state, it is placed relatively laterally on the workbench 1 , at this time, the operator can perform loading and unloading. The aluminum rod A and the welding block B are respectively clamped and fixed on the clamping mechanism 2 before the material loading is welded. After blanking is welding, the welded aluminum rod A and welding block B are taken out from the clamping mechanism 2 . When the base 11 is in a vertical state, it is vertically perpendicular to the workbench 1, and the welding mechanism 3 performs welding work at this time. In this embodiment, one end of the base 11 is hingedly a...

Embodiment 2

[0053] The present application further provides an aluminum rod welding method, using the above-mentioned aluminum rod welding device to weld the aluminum rod A and the welding block B, including the following steps:

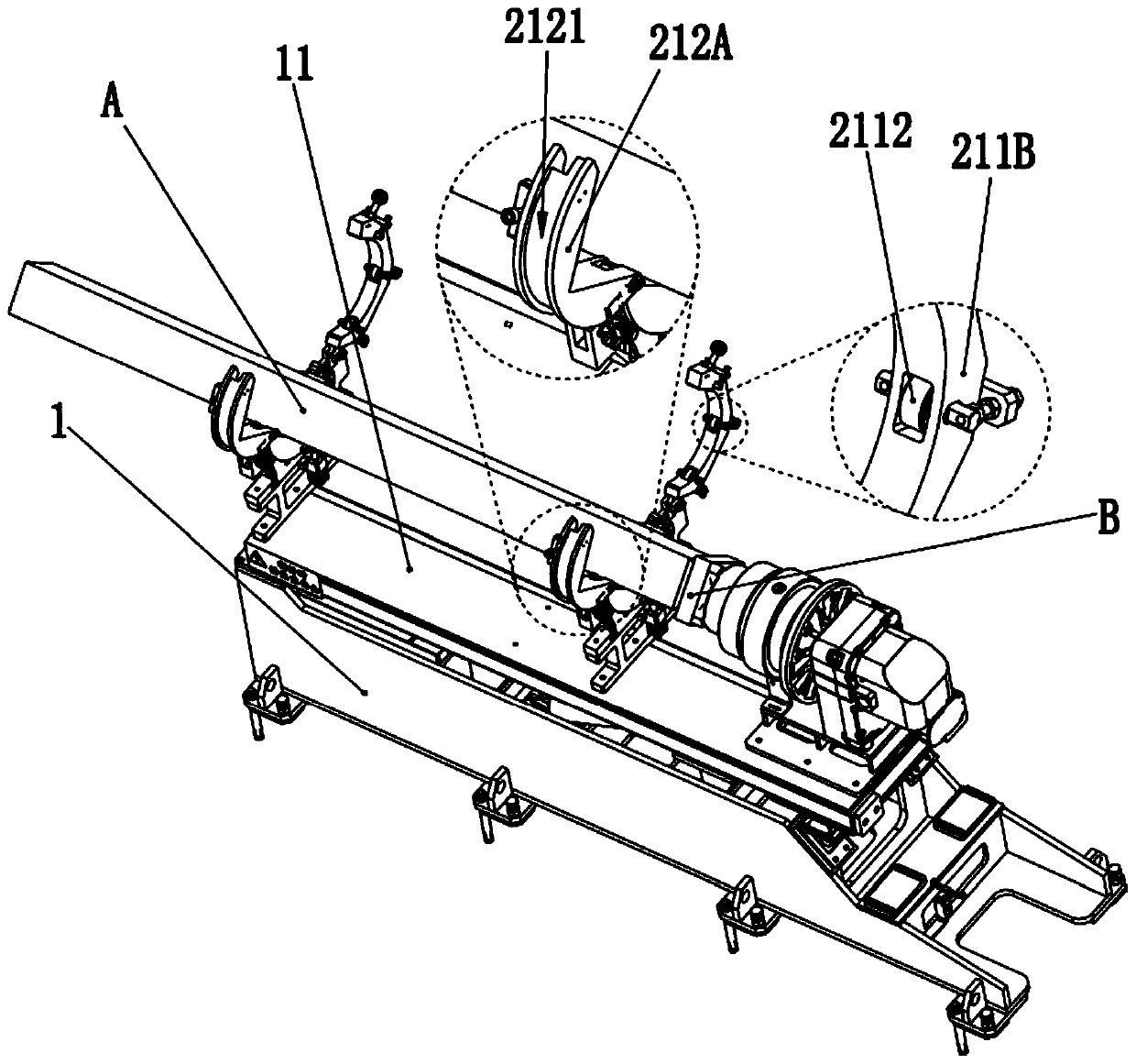

[0054] S1: The base 11 is in a horizontal state, fix the aluminum rod A to be welded on the first clamping part 21, and fix the welding block B on the second clamping part 22, so that the aluminum rod A and the welding block B are mutually abut and be at the same level.

[0055] Specifically, during the feeding process, the base 11 is placed laterally on the workbench 1, the aluminum rod A is placed in the accommodating cavity 212C of the limit seat 212 of the first clamping member 21, and the position of the limit seat 212 is locked. The two arc-shaped parts 212A lock and fix the opening and closing part 211B of the support base 211 and the seat part 211A, so that the limiting base 212 is accommodated in the cavity 211C to rotate relative to the support base 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com