Pneumatic clamping device for feeding machine

A pneumatic clamping and blanking machine technology, applied in metal processing and other directions, can solve the problems of easy deviation of materials and affect blanking accuracy, and achieve the effect of improving contact area, improving reliability, and being easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

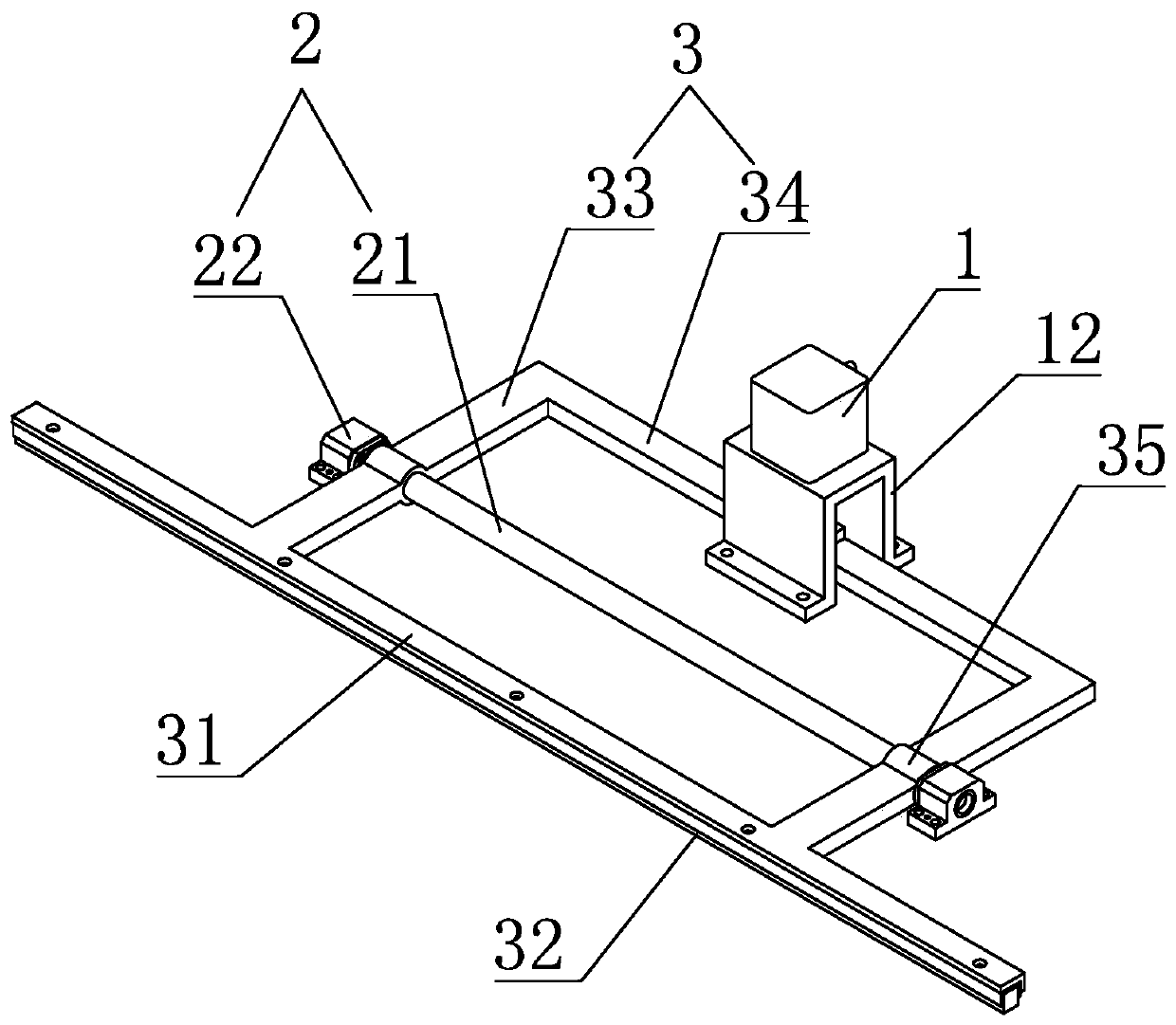

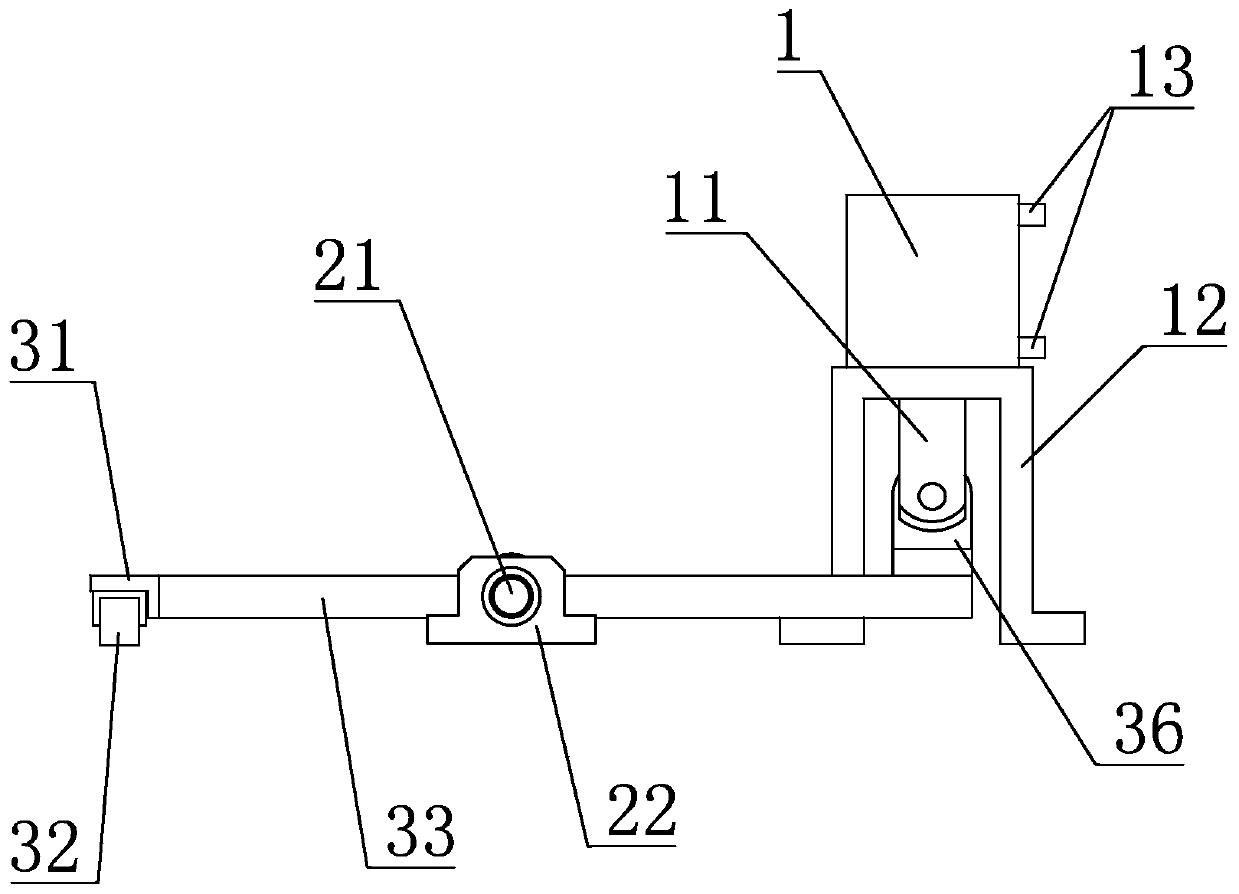

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited thereto.

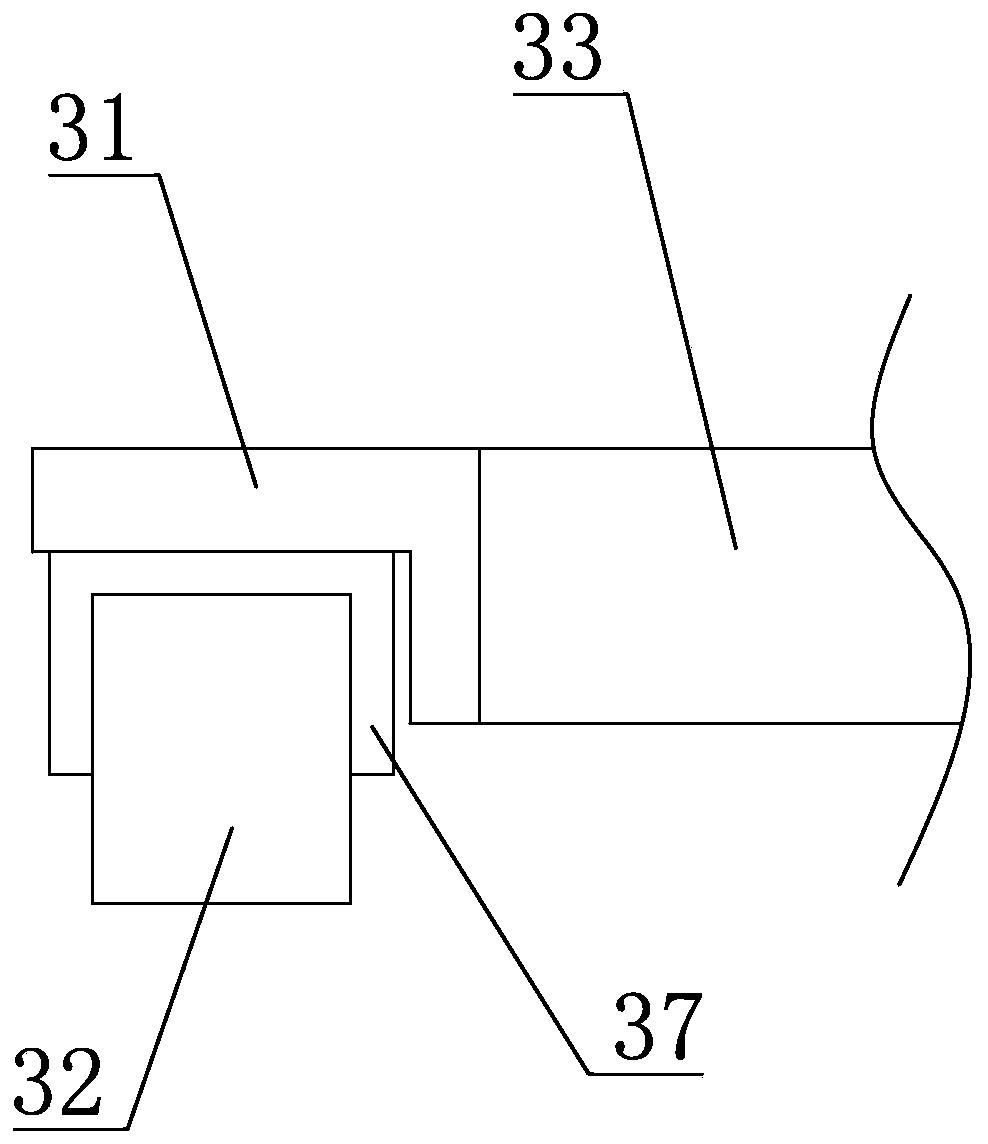

[0014] refer to Figure 1-3 , a pneumatic clamping device for a blanking machine, including a cylinder 1, a fulcrum frame 2 and a press frame 3, the middle part of the press frame 3 is rotatably connected to the fulcrum frame 2, and one end of the press frame 3 is connected to the The cylinder rod 11 of the cylinder 1 is hinged, and is driven to move up and down by the cylinder 1 , the other end is provided with a workpiece pressing plate 31 , and the lower side of the workpiece pressing plate 31 is provided with a rubber pad 32 .

[0015] Specifically, the upper and lower ends of the cylinder 1 are provided with air pipe joints 13 for connecting the air pipes, and the two air pipes connected by the two air pipe joints 13 are connected to the two ports on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com