Phenol-aldehyde impregnation method for modified plantation wood

A technology for plantation and wood, applied in the direction of impregnating wood, wood heating, wood impregnation, etc., can solve the problems of high equipment and process requirements, inconvenient promotion and utilization, etc., to improve the impregnation effect and uniformity, and improve the degree of immersion and uniformity. degree, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

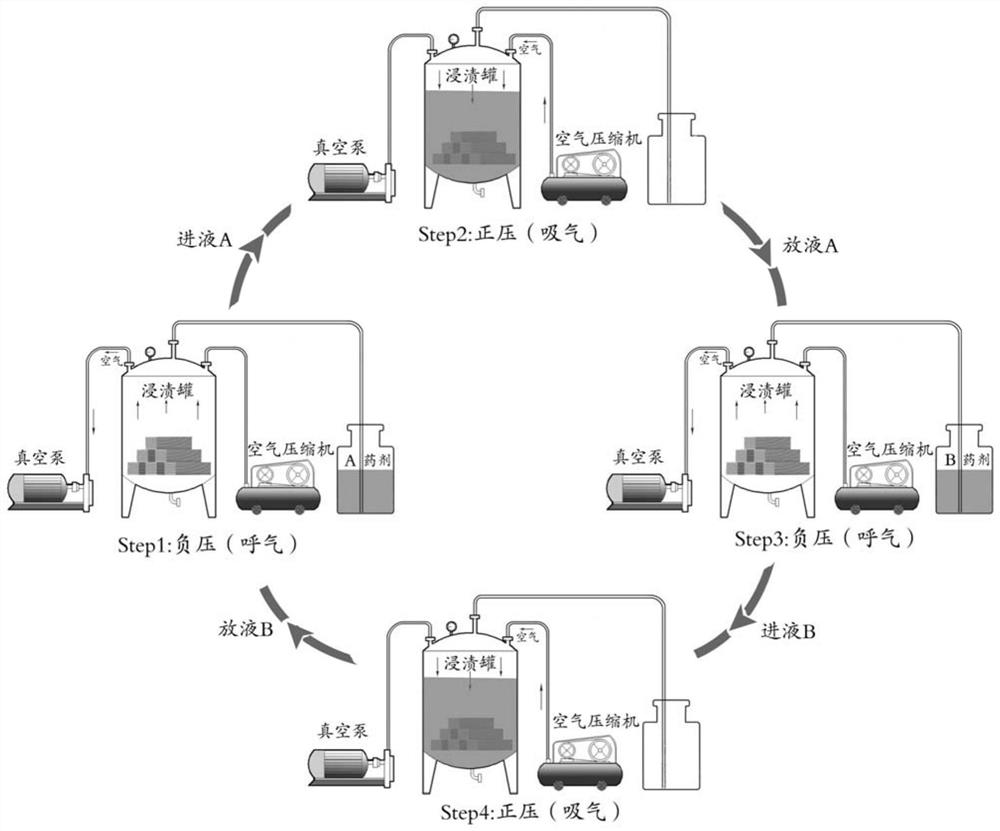

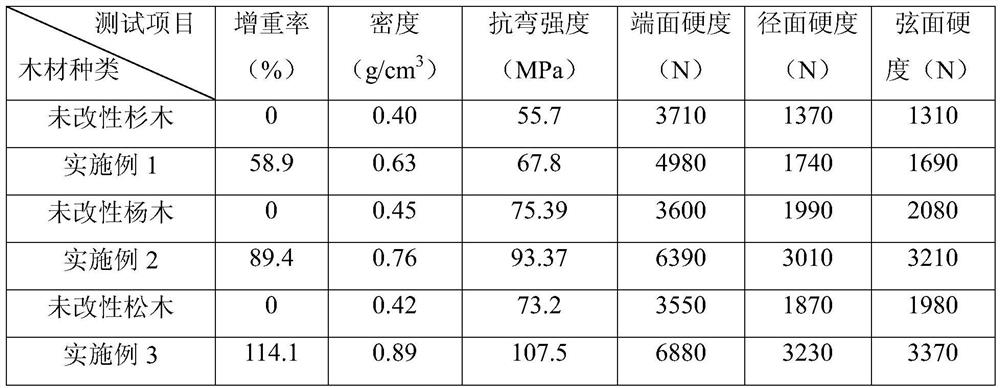

[0027] A method of phenolic-aldehyde impregnated modified plantation forest timber of the present invention, such as figure 1 shown, including the following steps:

[0028] (1) The Chinese fir timber is sawn into a size of 10mm×10mm×200mm, and dried to a moisture content of 12%. Dissolve 50g of NaOH in 117g of water, mix evenly with 188.22g of molten phenol, make A liquid, and set aside. Put the fir wood with a moisture content of 12% after drying into the impregnation tank, vacuumize the impregnation tank to -0.085MPa, and keep the pressure for 10 minutes, so that the air in the wood cell space is drawn out, and then start to enter the liquid, passing through the tank The negative pressure of the medicine A liquid is sucked into the tank and does not pass through the wood. After entering the liquid A, the negative pressure is unloaded, and then a positive pressure of 0.5MPa is applied to the tank, and the pressure is kept for 50 minutes. A thrust of liquid A makes the impre...

Embodiment 2

[0032] A method of phenolic-aldehyde impregnated modified plantation forest timber of the present invention, such as figure 1 shown, including the following steps:

[0033] (1) Poplar wood is sawn into 20mm×20mm×400mm, and dried to a moisture content of 10%. Dissolve 60g of NaOH in 90g of water, melt and mix with 188.22g parts by weight of phenol evenly, make A liquid, and set aside. Put the dried fir wood with a moisture content of 10% into the impregnation tank, vacuumize the impregnation tank to -0.095MPa, keep the pressure for 20 minutes, and then start to enter the liquid, and suck the drug A liquid into the tank through the negative pressure in the tank There is no wood in the tank. After entering the liquid A, unload the negative pressure, and then apply a positive pressure of 0.9MPa to the tank, and keep the pressure for 40 minutes. Completely, and accelerate the speed of dipping, can effectively shorten the dipping time, and then discharge excess A liquid.

[0034]...

Embodiment 3

[0037] A method of phenolic-aldehyde impregnated modified plantation forest timber of the present invention, such as figure 1 shown, including the following steps:

[0038] (1) Saw pine wood into 40mm×40mm×800mm, and dry to 8% moisture content. Dissolve 70g of NaOH in 70g of water, melt and mix with 188.22g parts by weight of phenol to prepare A liquid, and set aside. Put the dried fir wood with a moisture content of 10% into the impregnation tank, vacuumize the impregnation tank to -0.1MPa, keep the pressure for 30 minutes, and then start to enter the liquid, and suck the liquid A into the tank through the negative pressure in the tank There is no wood in the tank. After entering the liquid A, unload the negative pressure, and then apply a positive pressure of 1.1MPa to the tank, and keep the pressure for 30 minutes. Complete, and accelerate the speed of dipping, can effectively shorten the dipping time; discharge excess A liquid.

[0039] (2) Vacuumize the dipping tank th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com