Automatic clamping sling for engine cover

An engine cover and automatic clamping technology, applied in the field of EMS conveying system, can solve the problems of unobstructed passage, occupying ground logistics passage and material rack storage area, and crowded process area, so as to improve the automation rate and meet the needs of high-paced production. , the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

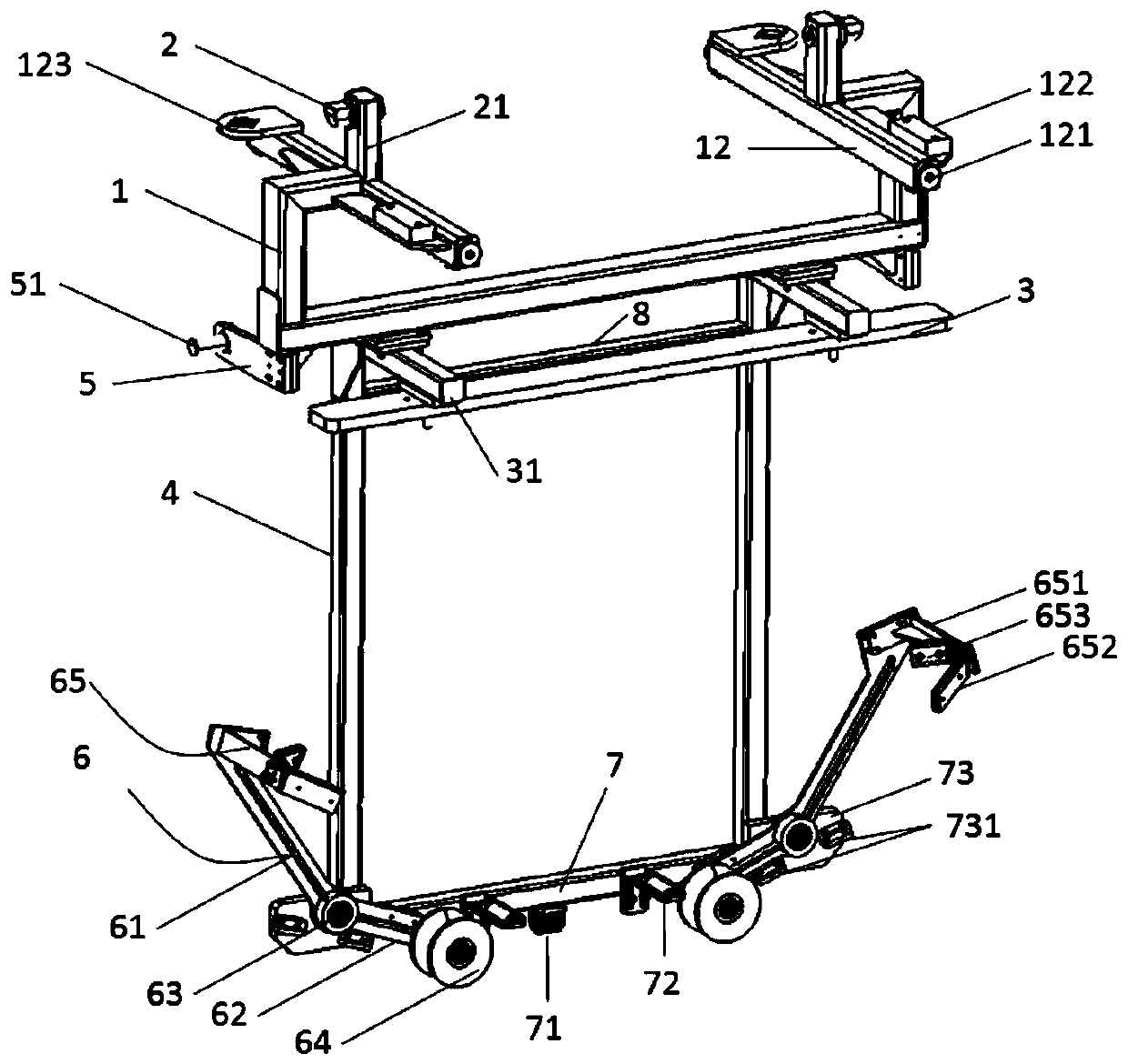

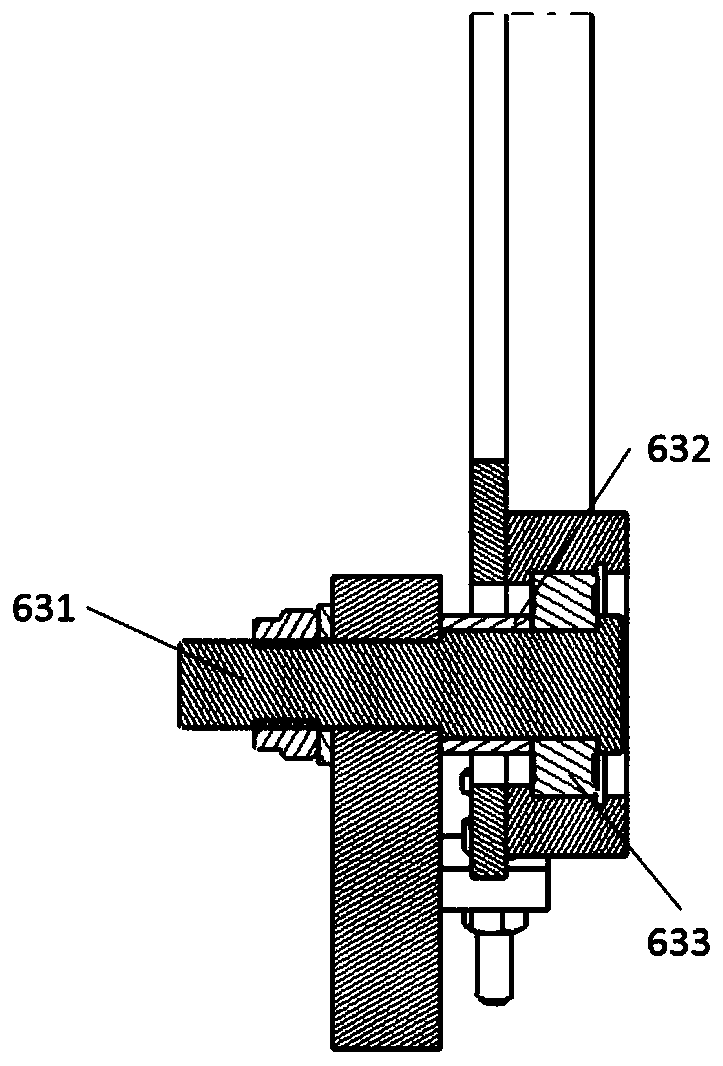

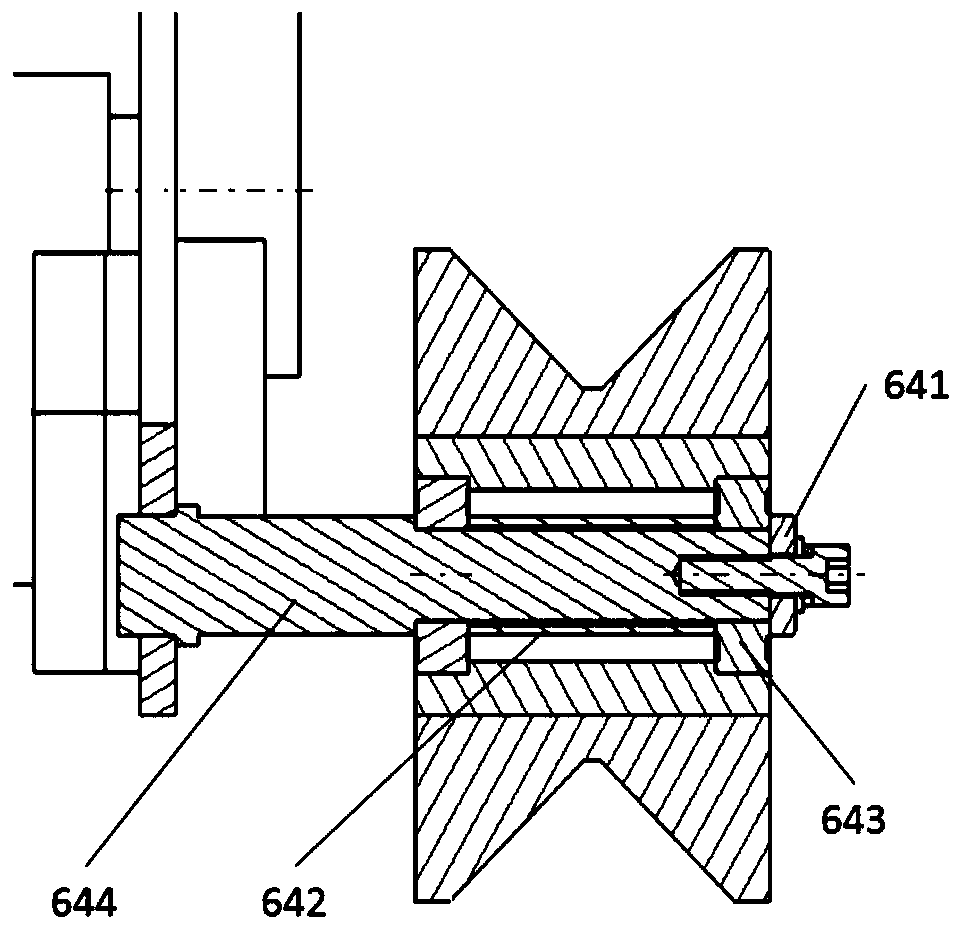

[0031] An engine cover automatic clamping spreader, such as figure 1 , the spreader includes a positioning mechanism, a bracket mechanism and a plurality of lever mechanisms 6, the positioning mechanism is fixed above the bracket mechanism, the lever mechanism 6 includes a guide rod 61, a connecting rod 62, a rotating wheel 63 and a supporting wheel 64, and the rotating wheel 63 is rotatably connected with the bottom angle of the bracket mechanism. The guide rod 61 is fixed on the end of the rotating wheel 63 away from the bracket mechanism. The connecting rod 62 is fixed on the end of the rotating wheel 63 close to the bracket mechanism. The support member 65 on the edge of the engine cover, the other end of the connecting rod 62 is provided with a supporting wheel 64 that carries the bottom of the engine cover. The wheel 64 and the support member 65 abut against the bottom and the edge of the engine cover respectively, and are in a clamped state.

[0032] The support member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com