Stacking and transferring system for shaft products

A technology for products and shafts, which is applied in the field of stacking and transfer systems for shaft products, can solve the problems of circumferential rotation error, difficulty in achieving circumferential clamping and positioning, and large space occupation of storage areas, so as to prevent circumferential rotation and improve Efficiency and precision, the effect of meeting the requirements of transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

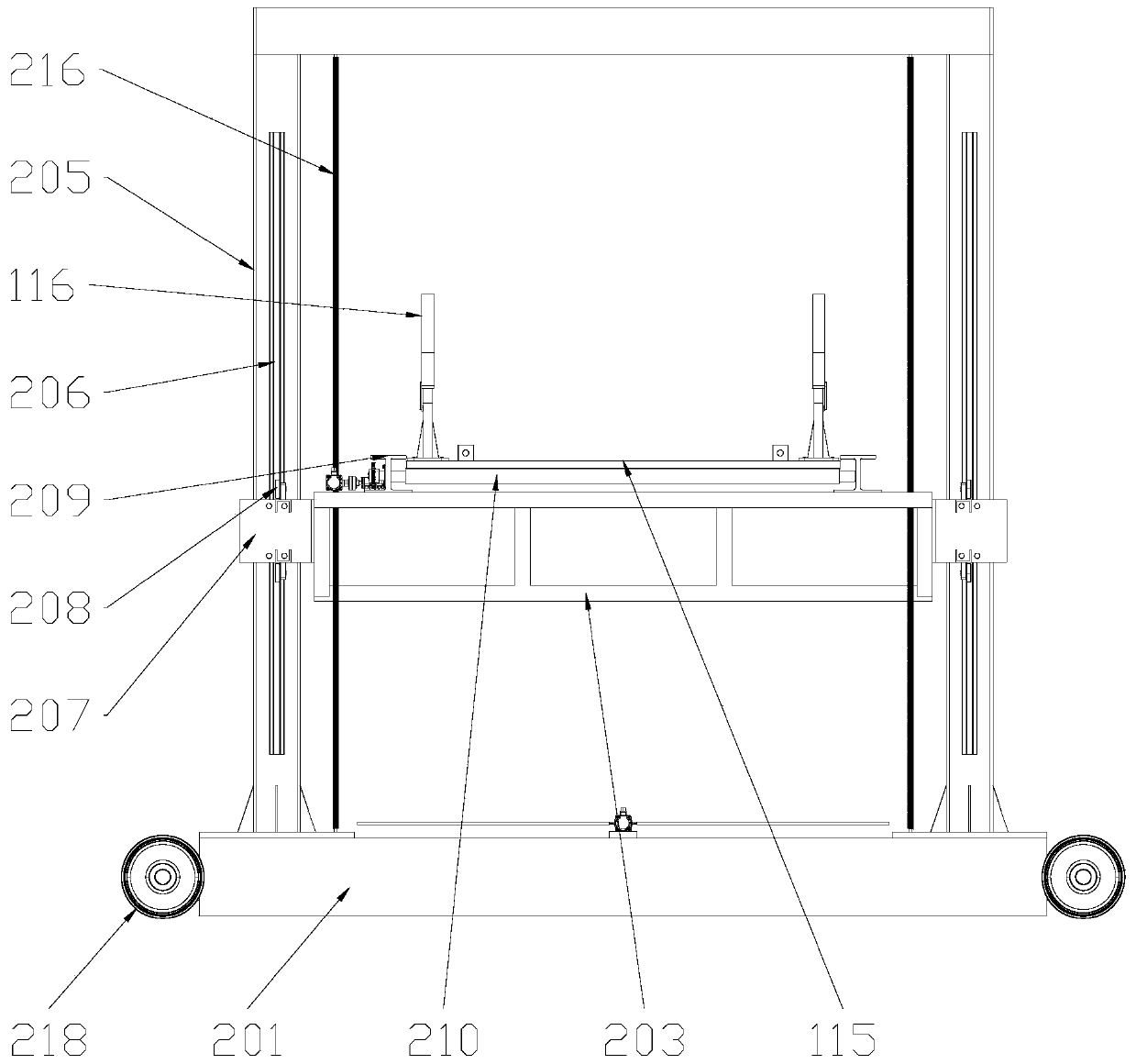

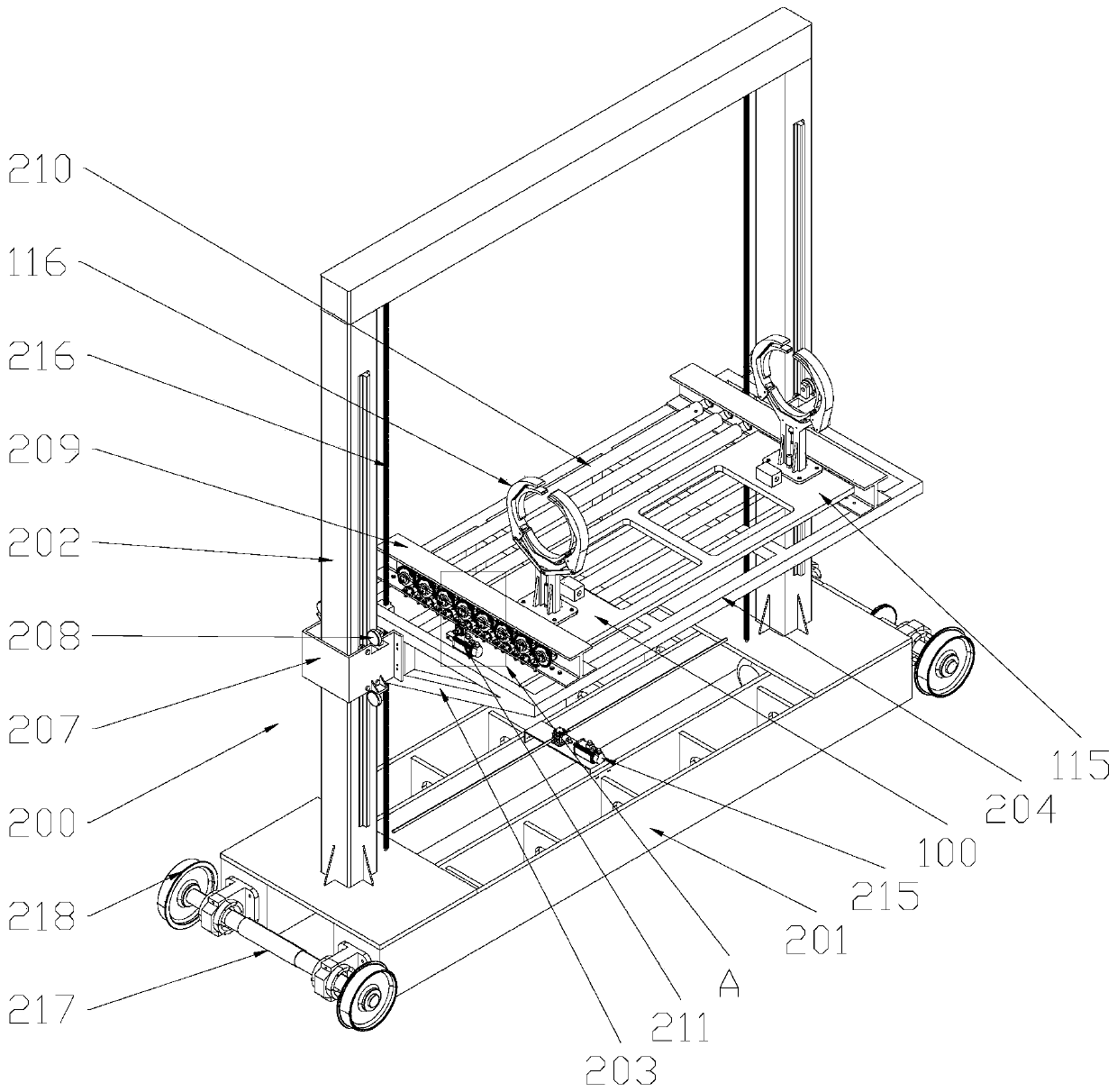

[0047] Such as figure 1 Shown is a schematic structural view of an embodiment of the shaft product stacking and transferring system of the present invention. The stacking and transfer system for shaft products in this embodiment includes a stacker 200 and a pallet 100 .

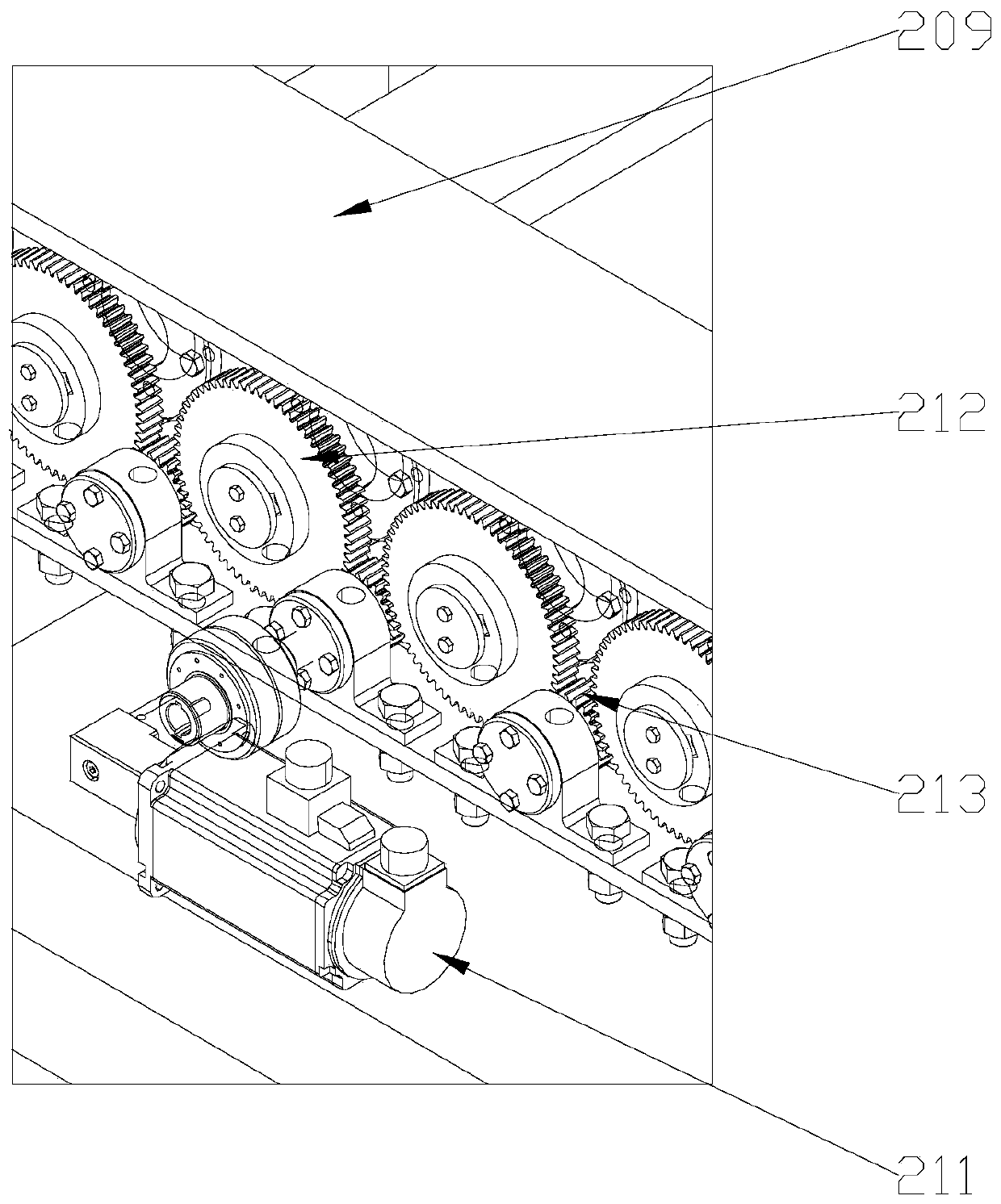

[0048] The stacker of the present embodiment includes a chassis 201, on which a vertical slide rail 202 is provided, on which a lifting frame 203 slidingly fitted is provided on the vertical sliding rail 202, and on the lifting frame 203 is provided with a structure for transporting the accompanying fixture 100 to A warehouse or transport mechanism 204 that receives pallets 100 from a warehouse. The lifting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com