Nickel-containing wastewater filtration system in production process of aminophenazone

A filtration system and production process technology, applied in the direction of filtration circuit, filtration separation, water pollutants, etc., can solve the problems such as the difficulty in cleaning the sedimentation layer at the bottom of the sedimentation tank, the difficulty in ensuring the sedimentation time of the sedimentation tank, and the incomplete sedimentation of Ni in the washing water, etc. , to achieve the effects of easy release and cleaning, reduced accumulation, and increased cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

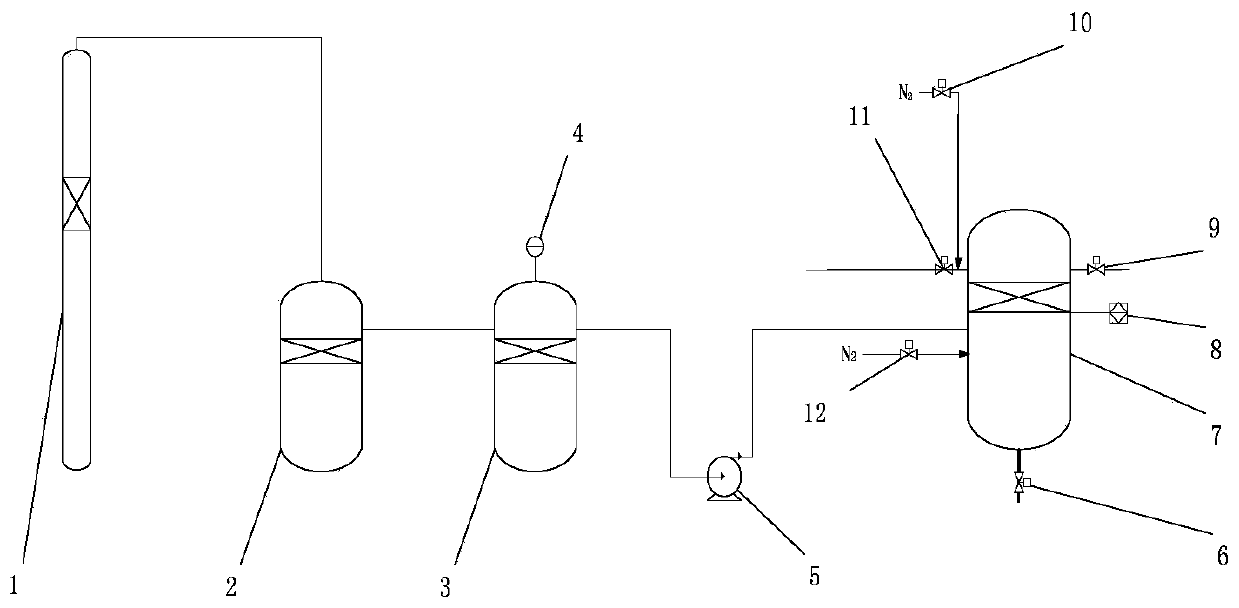

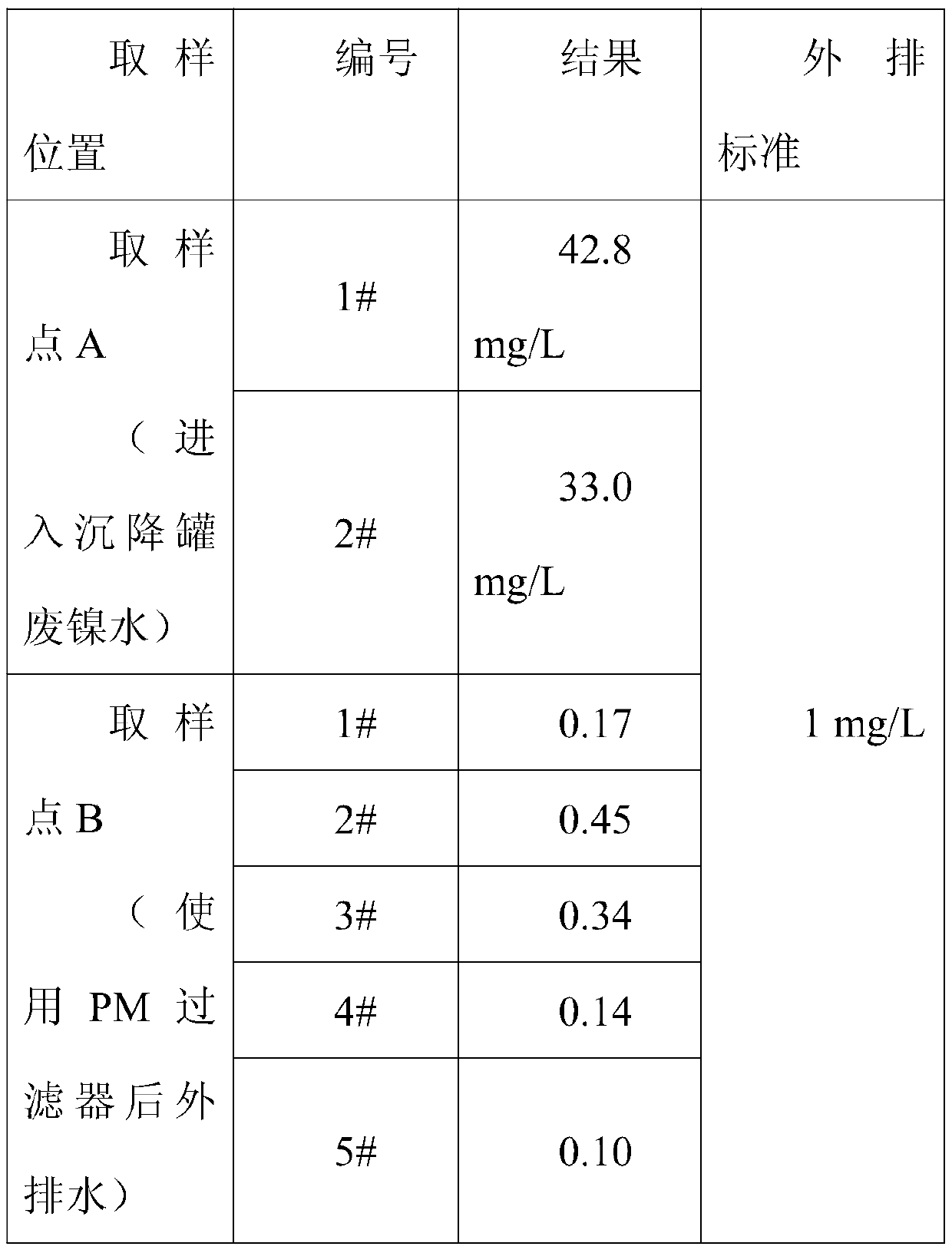

[0020] 1. The washing water flows out from the washing tower and enters the primary settling tank. After settling, it overflows to the filtrate storage tank through the overflow pipeline of the primary settling tank. The infusion pump is based on the remote liquid level of the filtrate storage tank. Turns on and turns off automatically at 1.0m. After the infusion pump is started, the emptying valve on the PM filter opens automatically, and automatically closes after 4.5 minutes. At the same time, the clear liquid valve automatically opens to filter. During the filtering process, pay attention to the PM filter pressure sensor to ensure that its pressure is maintained at 0.15-0.2MPa. Until the liquid level of the filtrate storage tank reaches 1.0m, the pump is automatically closed, and the clear liquid valve is automatically closed.

[0021] 2. Perform a recoil operation every 4 days. When backflushing operation, first open the clear liquid valve, then open the filter valve, af...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap