Heat pump type double-fluid dehumidification temperature rising drying machine and drying chamber

A dual-fluid, dryer technology, applied in heat pumps, dryers, fluid circulation arrangements, etc., can solve the problems of high heat loss due to dehumidification, high heating power consumption, weak humidity and temperature adjustment capabilities, etc., to achieve small footprint, Avoid loss, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

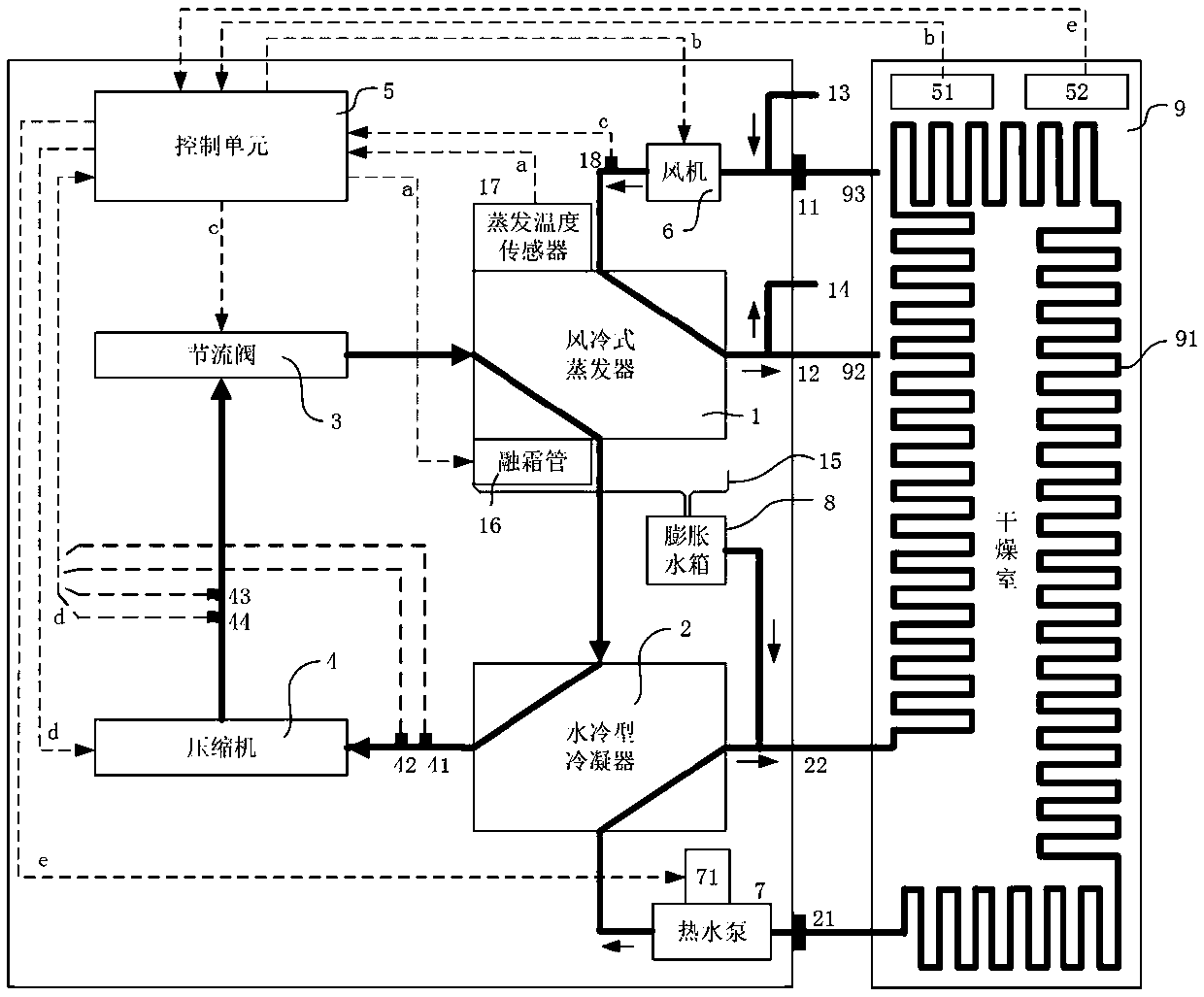

[0022] Such as figure 1 As shown, the heat pump type dual-fluid dehumidification and heating dryer in this embodiment includes a heat pump unit body with a refrigerant circuit and a control unit 5, a fan 6, and a hot water pump 7. The refrigerant circuit includes air-cooled evaporators connected in series. 1, water-cooled condenser 2, throttle valve 3, compressor 4, the control end of the throttle valve 3 is connected to the control unit 5, and the heat pump unit body is also provided with a moist air inlet 11 and a dry air outlet 12 , the hot water return port 21 and the hot water output port 22, the humid air inlet 11 communicates with the air-cooling passage entrance of the air-cooled evaporator 1 through the fan 6, and the dry air outlet 12 communicates with the wind of the air-cooled evaporator 1. The cold channel outlet is connected, the hot water return port 21 is connected with the water cooling channel inlet of the water-cooled condenser 2 through the hot water pump 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com