Maintenance scheme obtaining method, device and system

A technology for obtaining methods and solutions, which can be used in hoisting devices, lifting equipment safety devices, instruments, etc., to solve problems such as large manpower and time, low manual maintenance efficiency, and complex mechanical equipment structures, saving manpower and time, avoiding The effect of lower maintenance efficiency and shorter discovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

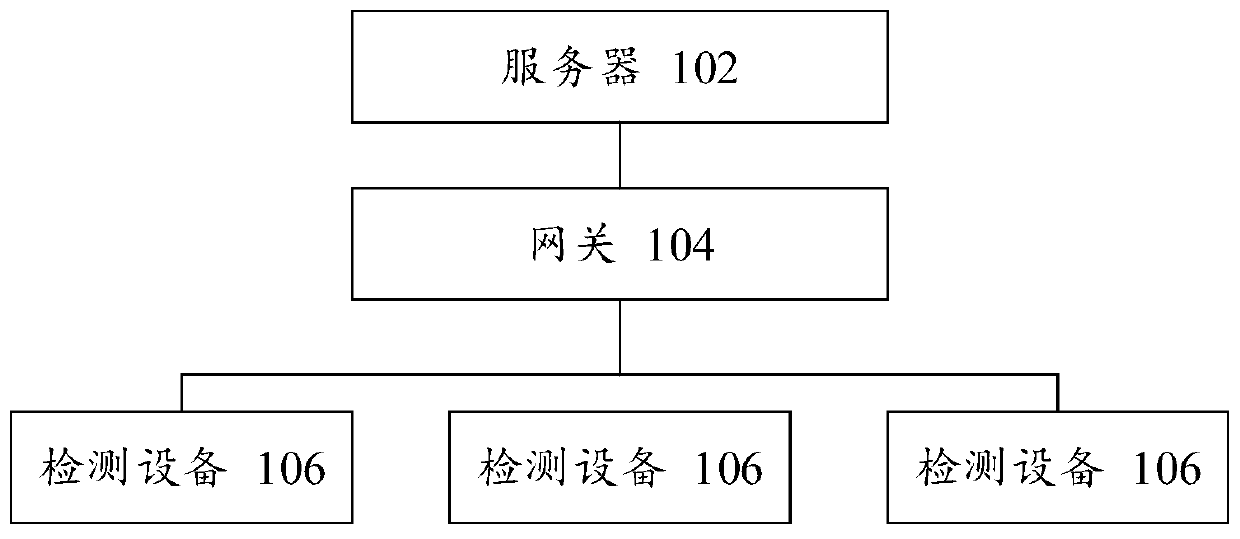

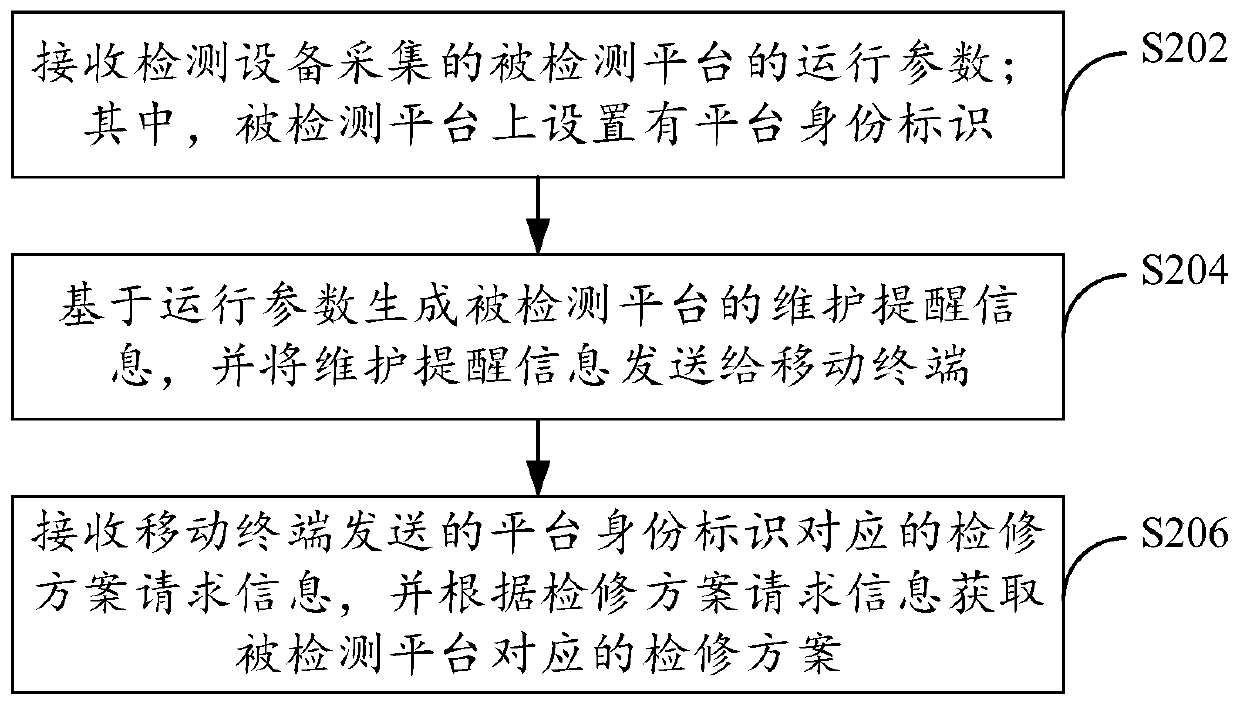

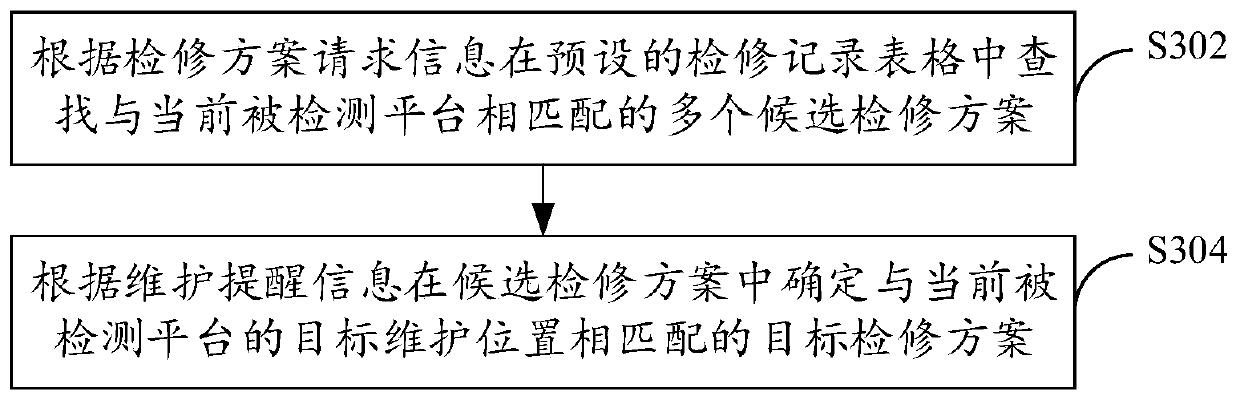

[0026] This embodiment provides a method for acquiring a maintenance plan, which can be executed by a server. In order to better understand the technical solution of the present disclosure, the following combination figure 1 Firstly, the application scenario of the method for obtaining the maintenance scheme is described.

[0027] refer to figure 1 , which shows a schematic structural diagram of a system for acquiring a maintenance scheme for realizing a maintenance scheme acquisition method, the system includes the above-mentioned server 102 and at least one detection device 106 connected to the server 102, the system also includes a gateway 104, and the server 102 It is connected to the detection device 106 through the gateway 104 . Wherein, the server 102 may be, for example, a UNIX (Eunice) server or a PC (Personal Computer, personal computer) server. The server 102 may include a processor and a storage device; a computer program is stored on the storage device, and whe...

example 1

[0045] Example 1: If the detection device includes a count sensor, receive the lift count parameter collected by the count sensor.

[0046] In practical applications, the frequency sensor can use a laser displacement sensor with high accuracy and an ultrasonic ranging sensor with a low cost; among them, the ultrasonic ranging sensor can be used to collect the parameters of the lifting times of the elevator and can also collect the parameters of the elevator at the same time. Lifting speed parameters, which can reduce the number of installations of a detection device and reduce costs.

[0047] Based on this, the server can compare the parameters of the number of lifts collected by the number sensor with the preset threshold of lift times (such as 5000 times), and when the number of lifts reaches 5000 times, a preventive maintenance reminder message is sent to the mobile terminal to remind the staff Perform inspections and preventive maintenance on lifting components of associat...

example 2

[0048] Example 2: If the detection device includes a speed sensor, receive the lifting and lowering speed parameters of the elevator collected by the speed sensor.

[0049] In practical applications, the speed sensor may use a photoelectric speed sensor, a laser speed sensor, a radar speed sensor, and the like.

[0050] Based on this, the server can compare the lifting speed parameters collected by the speed sensor with the preset lifting speed range (such as 0.3m / s≤V≤1m / s). The mobile terminal sends a speed reminder message to remind the staff to carry out inspection and preventive maintenance on the components (such as stepper motors) that control the lifting speed of the relevant elevator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com