Pipeline measurement method based on multi-view vision

A multi-eye vision and measurement method technology, applied in the field of visual measurement, can solve the problems of complex process, high cost, low precision, etc., and achieve the effect of solving the complex measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

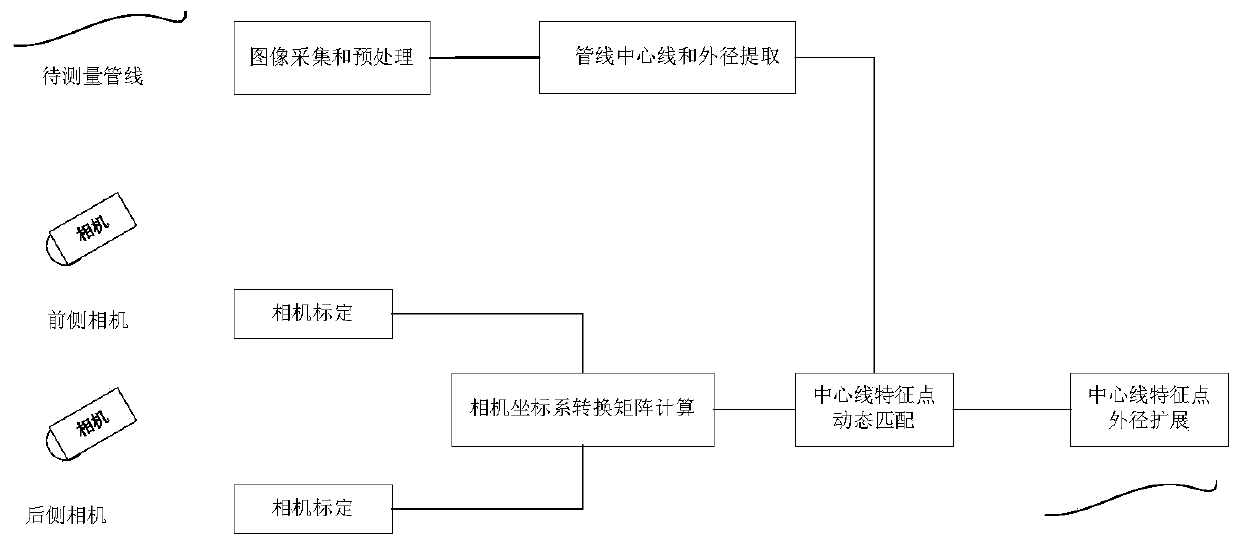

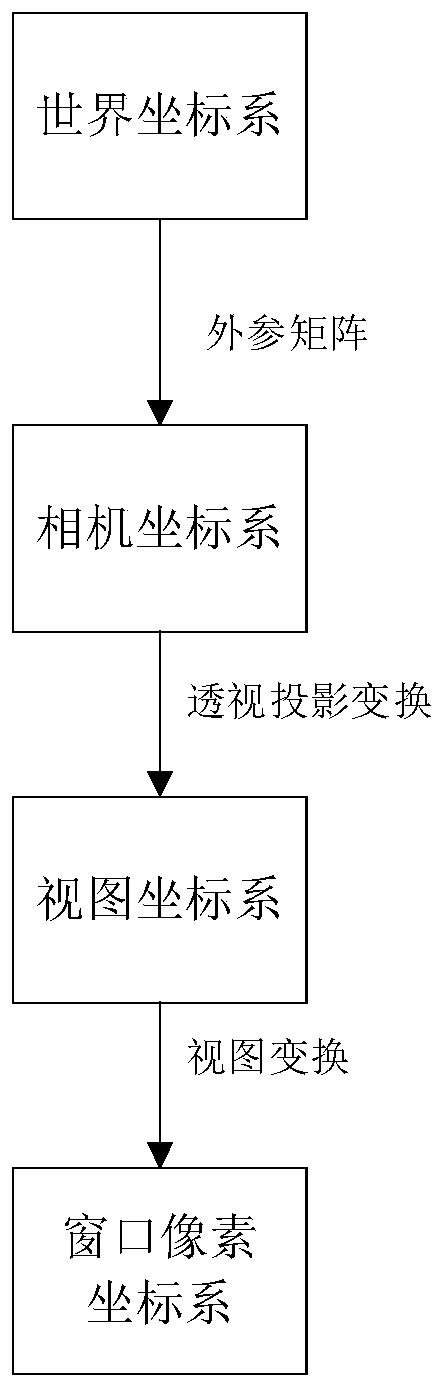

Method used

Image

Examples

specific Embodiment

[0050] (1) Image acquisition and preprocessing

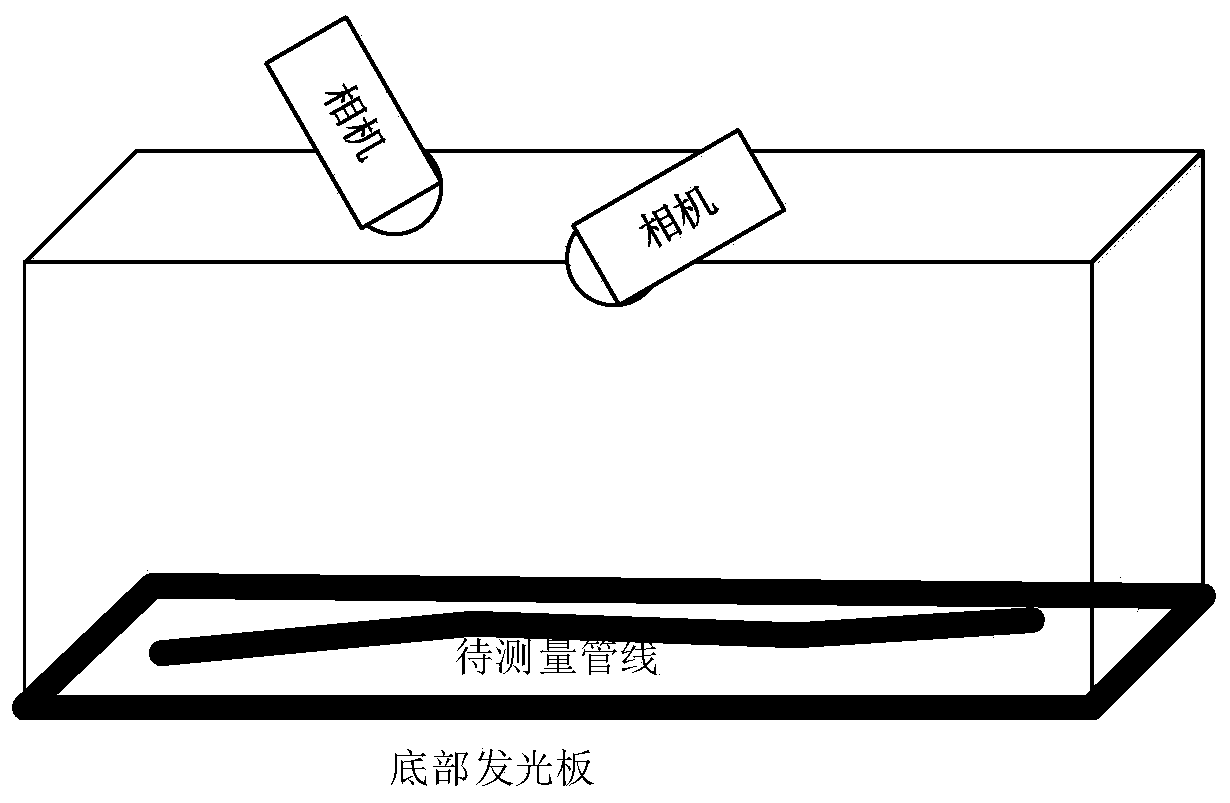

[0051] First build the image acquisition system, use a steel platform with a length of about 1.5m as the frame of the image acquisition system, and lay a light-emitting board at the bottom of the frame to eliminate the shadows caused by high-level light source lighting and simplify the image processing of the pipeline background. operate. If the desktop is used as the stage, the texture information on the desktop will cause great trouble. The strong light of the luminous board can make the background of the pipe picture close to white.

[0052] According to the accuracy analysis of the 3D reconstruction simulation of the ideal polyline segment, the image acquisition module needs to use a camera with at least 5 million pixels. Place the camera in the system frame, such as Figure 1-2 As shown, a camera is placed at the front and rear respectively to form a pair of camera groups. Take pictures of the pipelines to be measured pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com