Device for demonstration and testing of maglev train model

A technology of maglev train and model, applied in the field of electric traction drive, can solve the problem that the system cannot be unified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

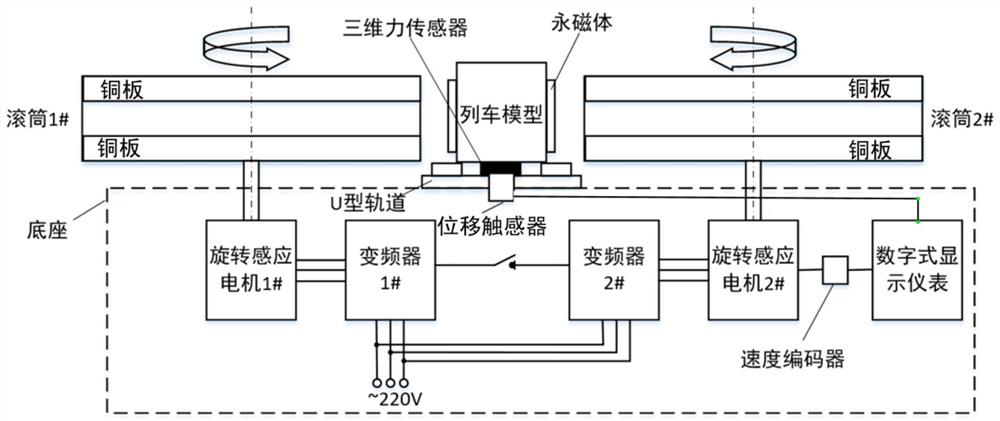

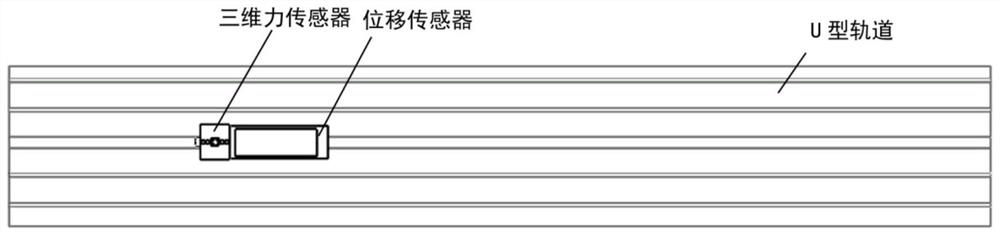

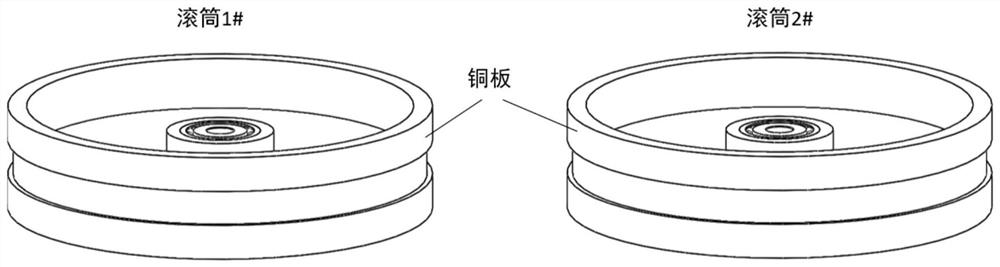

[0037] figure 1 It is a schematic diagram of the device structure for a maglev train model test of the present embodiment, referring to figure 1 , Permanent magnets are installed on both sides of the maglev train model, and the device includes: U-shaped track, two rollers and a base.

[0038] Two rotating induction motors (1# and 2#), two frequency converters (1# and 2#), speed encoders and digital display instruments are respectively installed on the base; two rollers (1# and 2#) The shaft center is perpendicular to the base, and is respectively connected with two rotating motors through rotating shafts. The two rotating motors turn in the opposite direction, and the working state of the rotating induction motor is controlled by the frequency converter to make it work in an electric state, which drives the drum to rotate, and produces relative motion with the permanent magnets on both sides of the car model to make the train model levitate.

[0039] The two frequency conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com