Multi-wavelength InGaN/GaN multi-quantum well structure based on GaN dodecahedral cone and preparation method thereof

A multi-quantum well structure and multi-quantum well layer technology, which is applied in the field of semiconductor light-emitting devices, can solve the problems of reducing the working efficiency and device life of semiconductor components, affecting the performance stability of GaN-based optoelectronic devices, surface damage and pollution, and achieving realization Large-scale growth and application, improved internal quantum efficiency, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

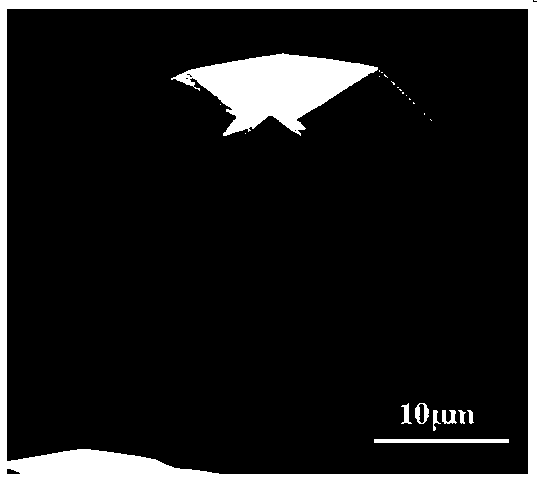

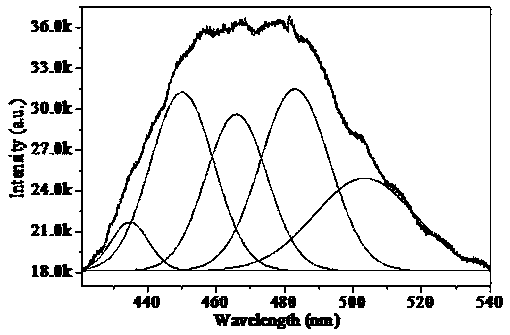

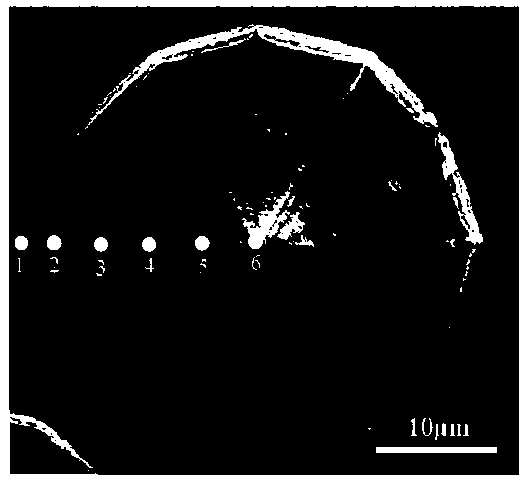

[0036] A multi-wavelength InGaN / GaN multiple quantum well structure based on GaN dodecahedral cones, through thermal H 4 PO 3 Etch the N-face self-supporting GaN substrate material to form a micro-nano GaN dodecahedron structure; use H 4 PO 3 The solution is heated and etched, and the micro-nano GaN dodecahedron is obtained by etching, and the InGaN / GaN multiple quantum well layer is grown on the GaN dodecahedron template by using metal organic chemical vapor phase epitaxy (MOCVD).

[0037] Such as figure 1 As shown, the micro-nano GaN dodecahedron is a dodecahedron composed of twelve triangular faces, and the space group of the wurtzite structure is , there are hexagonal rotational symmetry and mirror symmetry. The twelve-sided cone reflects the symmetry of the wurtzite structure. The structure of the twelve-sided cone is composed of six...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap