Cover tape and electronic component package

A technology of electronic components and cover tapes, which is applied in packaging, transportation and packaging, and packaging of fragile items, etc. It can solve the problems of not being able to fully control the floating of heat seals, and achieve the effect of suppressing floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

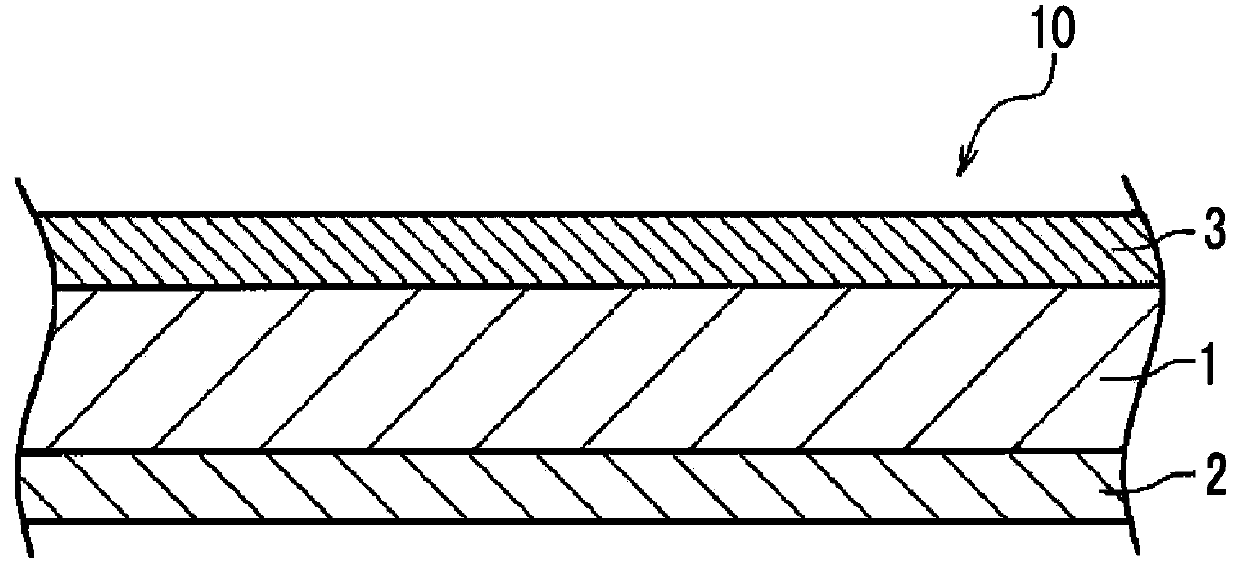

[0046] Preparation of cover tape: A biaxially stretched polyethylene terephthalate film (manufactured by Toyobo Co., Ltd., T6140) with a film thickness of 25 μm was prepared as a base material layer. Polyethylene (Wako Corporation: LM-015) was laminated as an intermediate layer on the base material layer so that the film thickness became 25 μm. After corona treatment was performed on this intermediate layer, an acrylic sealant resin (manufactured by Dainippon Ink Co., Ltd., A450A) was formed into a film so that the film thickness became 2 μm as the sealant layer, thereby obtaining figure 1 Cover tape with layer structure shown.

[0047] In addition, the measurement of the dimensional change rate of the polyethylene layer used as an intermediate|middle layer was performed by the following method. First, in an environment of 23° C. and a relative humidity of 50%, the above-mentioned polyethylene film, which is the intermediate layer, was cut into 400 mm squares. The dimension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com