Mupirocin ointment and preparation method thereof

A technology of mupirocin and ointment, applied in the field of mupirocin ointment and preparation, can solve the problem of high cost of raw materials, and achieve the effects of stable content, excellent release and reasonable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

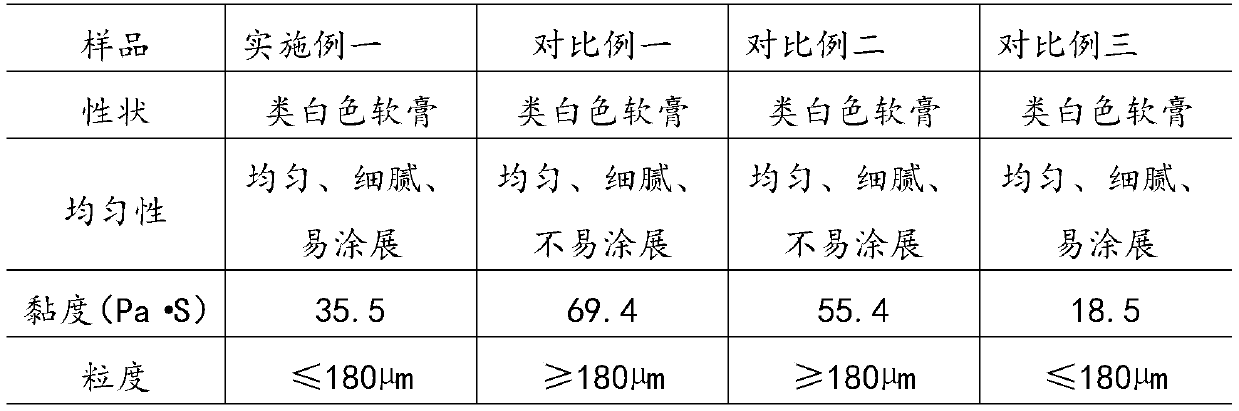

Examples

Embodiment 1

[0033] Take the raw material of mupirocin ointment by weighing following percentage by weight:

[0034] Macrogol-400: 78.4%, Macrogol-4000: 19.6%, Mupirocin: 2%.

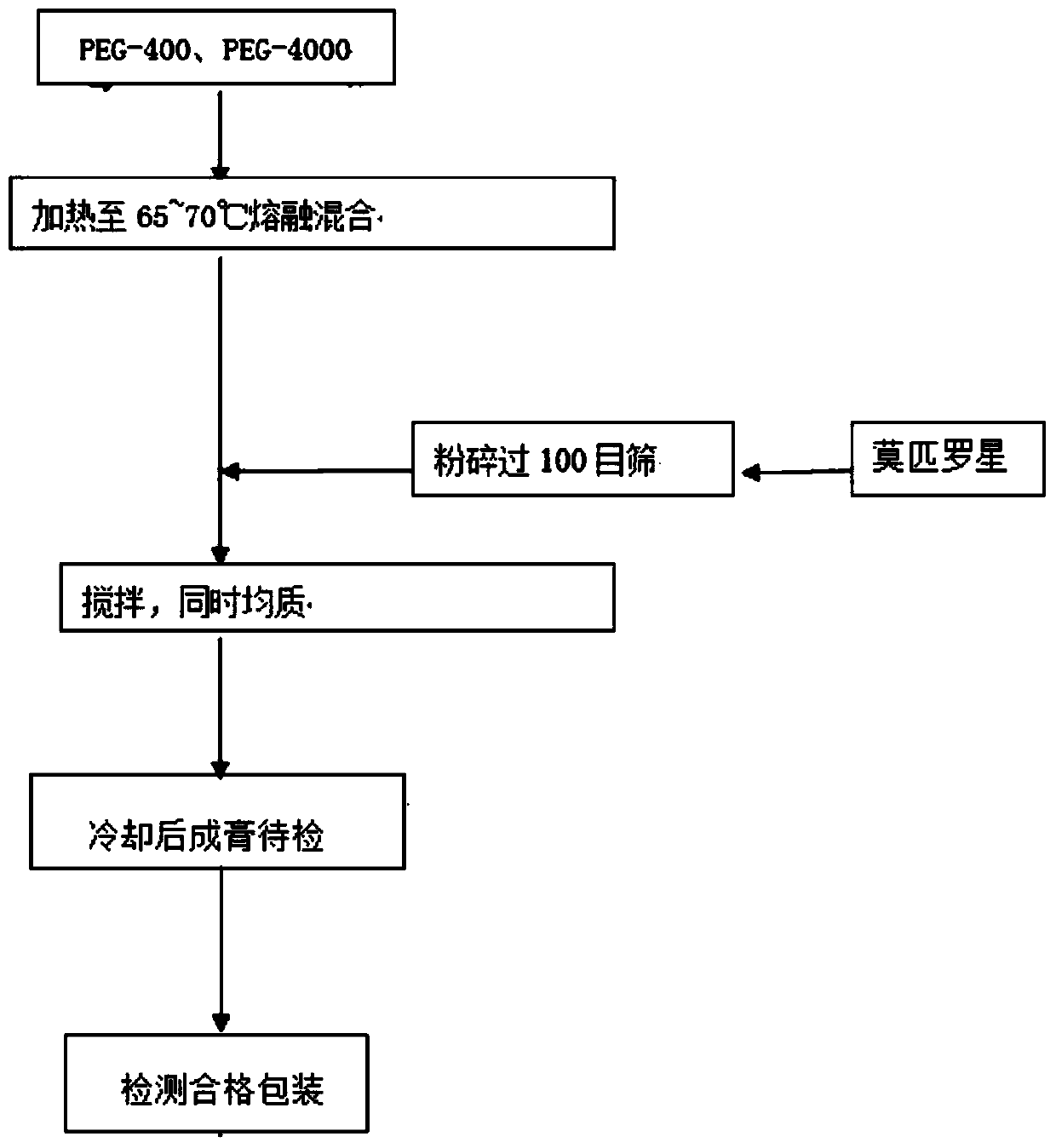

[0035] The preparation method of mupirocin ointment comprises the following steps:

[0036] Step S1: Melt polyethylene glycol-400 and polyethylene glycol-4000 at a temperature of 65°C to 70°C to obtain a mixed blank matrix;

[0037] Step S2: After pulverizing mupirocin, pass through a 100-mesh sieve, add the mixed blank matrix and stir for 20 minutes, and simultaneously turn on the homogenizer to grind for 5 minutes, and the stirring speed is 60r / min to obtain the ointment precursor;

[0038] Step S3: cooling the ointment precursor at 40°C for testing and packaging to obtain the mupirocin ointment.

Embodiment 2

[0040] Take the raw material of mupirocin ointment by weighing following percentage by weight:

[0041] Macrogol-400: 77.2%, Macrogol-4000: 20.8%, Mupirocin: 2%.

[0042] The preparation method of mupirocin ointment comprises the following steps:

[0043] Step S1: Melt polyethylene glycol-400 and polyethylene glycol-4000 at a temperature of 65°C to 70°C to obtain a mixed blank matrix;

[0044] Step S2: After pulverizing mupirocin, pass through a 100-mesh sieve, add the mixed blank matrix and stir for 30 minutes, and simultaneously turn on the homogenizer to grind for 8 minutes, and the stirring speed is 60r / min to obtain the ointment precursor;

[0045] Step S3: cooling the ointment precursor at 38° C. for detection and packaging to obtain the mupirocin ointment.

Embodiment 3

[0047] Take the raw material of mupirocin ointment by weighing following percentage by weight:

[0048] Macrogol-400: 76%, Macrogol-4000: 22%, Mupirocin: 2%.

[0049] The preparation method of mupirocin ointment comprises the following steps:

[0050] Step S1: Melt polyethylene glycol-400 and polyethylene glycol-4000 at a temperature of 65°C to 70°C to obtain a mixed blank matrix;

[0051] Step S2: After pulverizing mupirocin, pass through a 100-mesh sieve, add the mixed blank matrix and stir for 30 minutes, and simultaneously turn on the homogenizer to grind for 8 minutes, and the stirring speed is 60r / min to obtain the ointment precursor;

[0052] Step S3: cooling the ointment precursor at 42° C. for detection and packaging to obtain the mupirocin ointment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com