Modular impact crusher

An impact crusher, modular technology, applied in the direction of grain processing, etc., to achieve the effect of saving working space, improving the overall strength, and reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

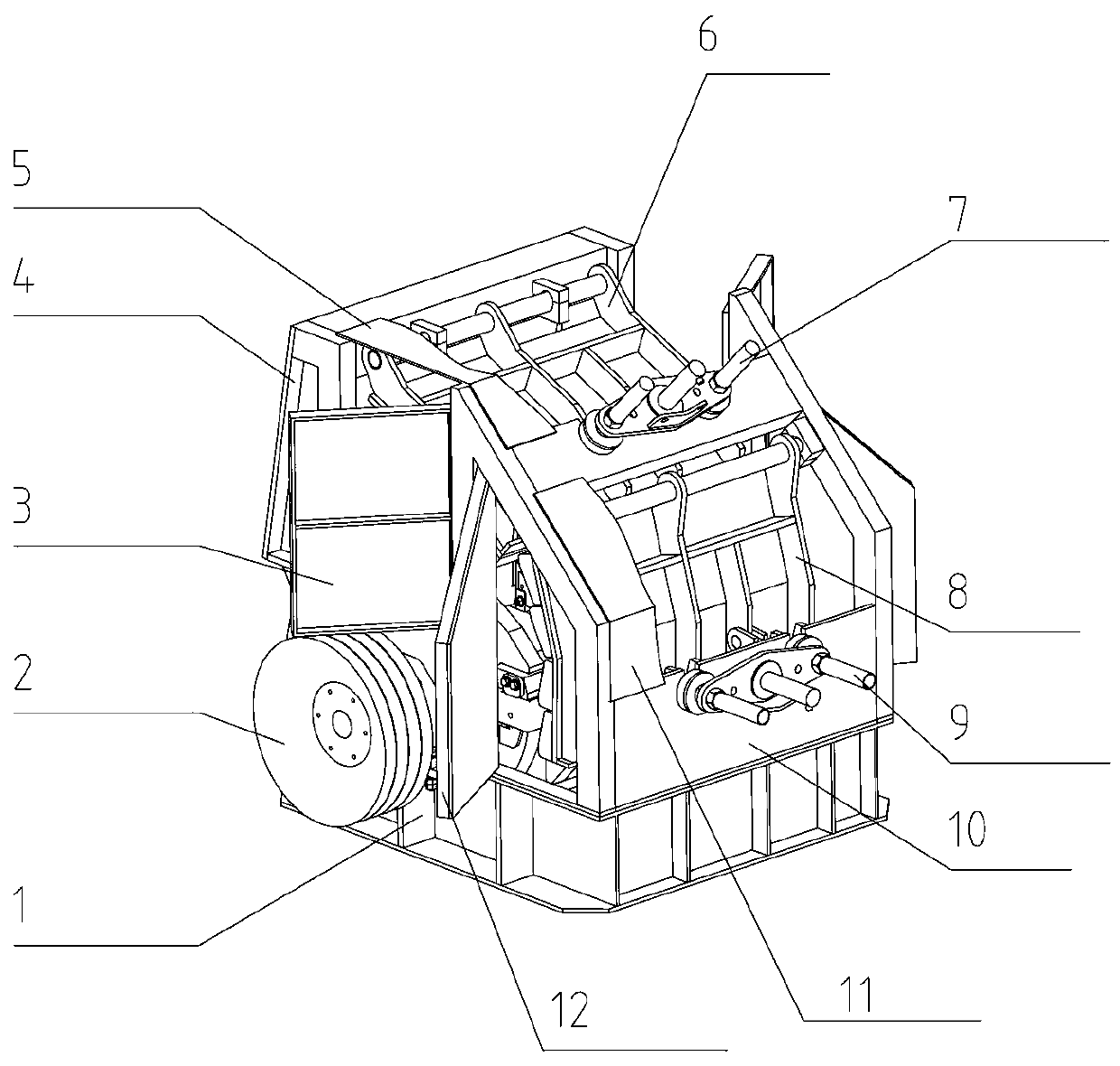

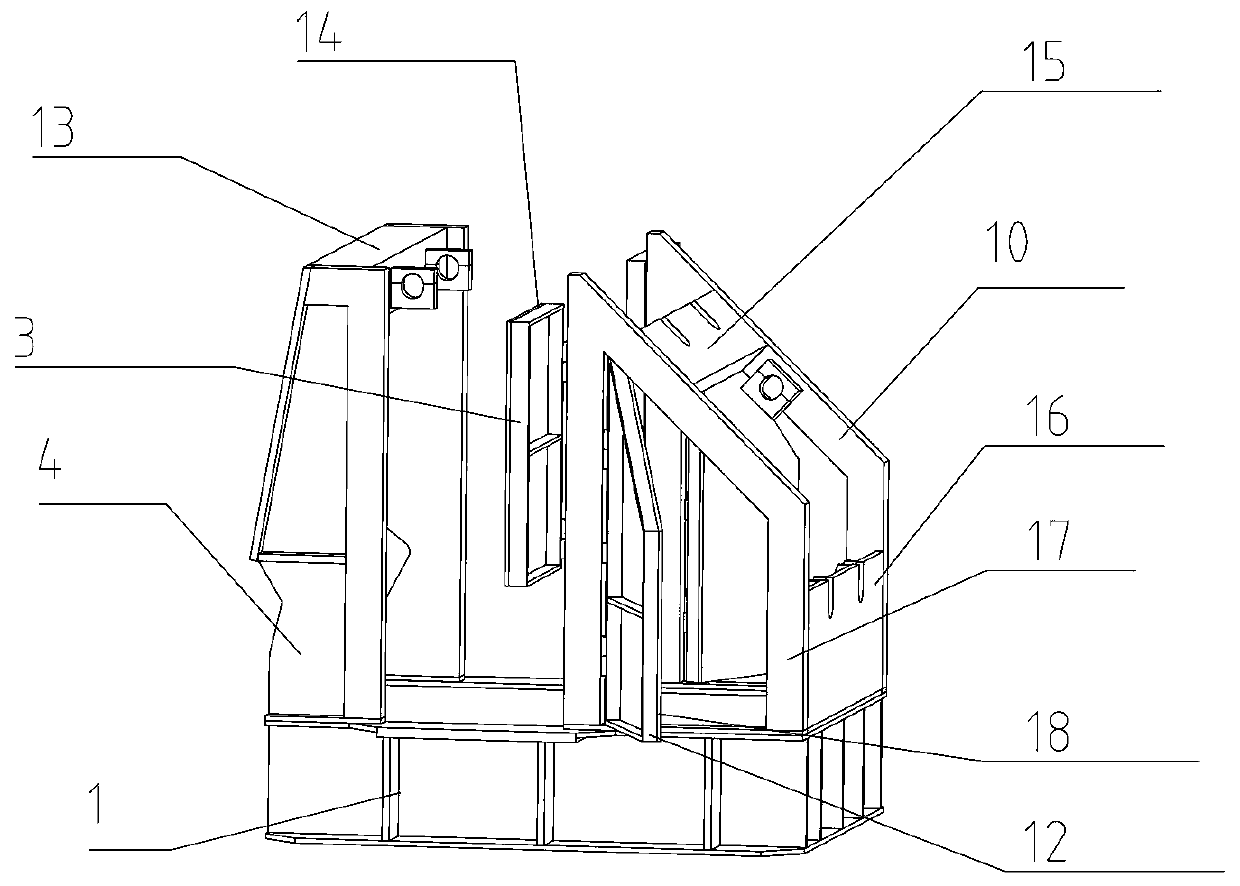

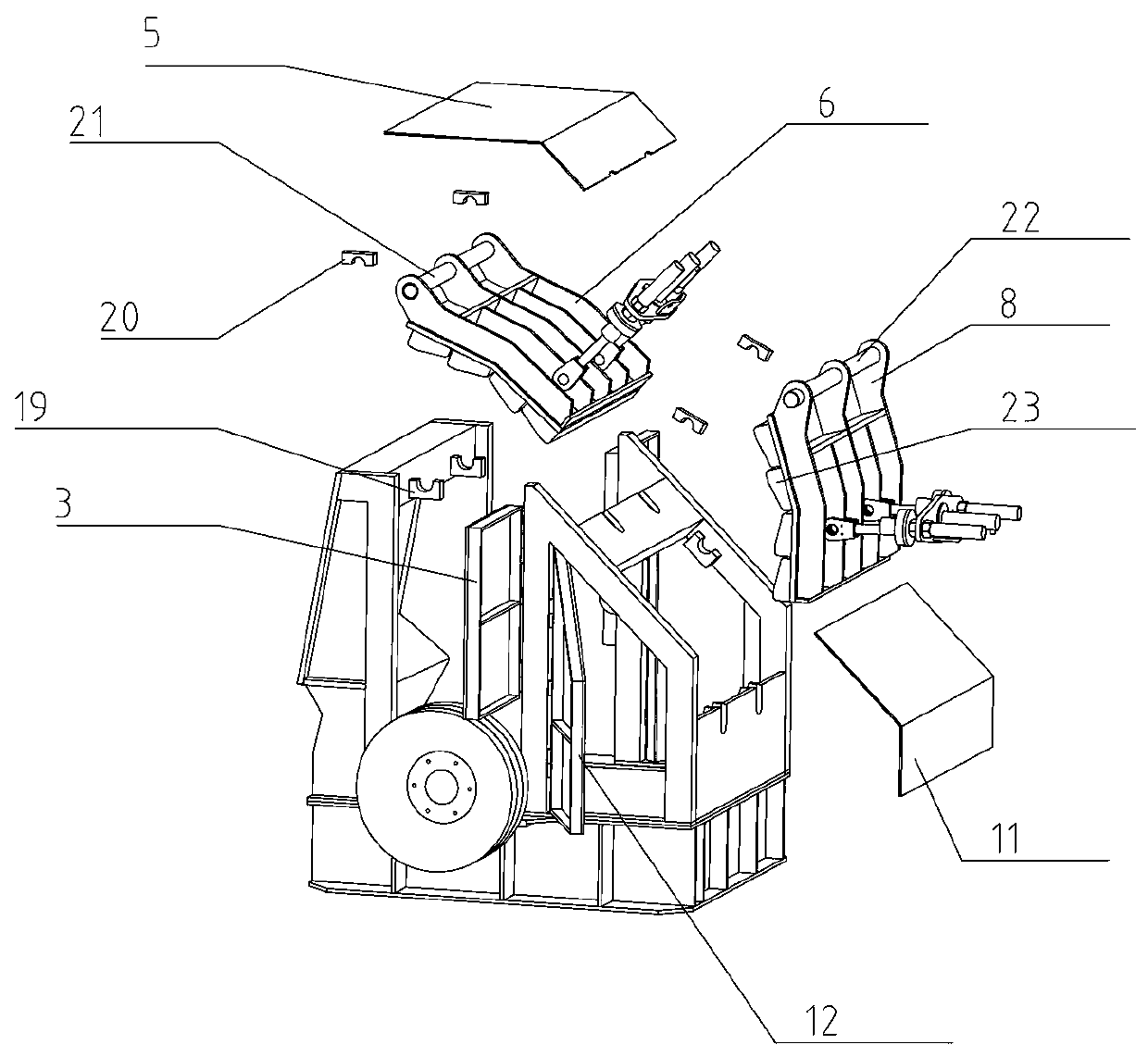

[0017] Such as Figure 1 to Figure 4 As shown, a modular impact crusher includes a base 1, a rotor part 2 is installed on the base 1, and a front frame 4 and a rear frame 10 are detachably installed on the base on both sides of the rotor part 2 through bolts. Both the frame 4 and the rear frame 10 adopt square steel as the frame structure foundation and are welded into shells. The openings of the front frame 4 and the rear frame 10 are arranged oppositely. The preferred rear frame is in the shape of a right-angled trapezoid. The side away from the front frame side is the short side of a right-angled trapezoid. The front frame 4 is located on the front side of the rotor component, that is, the direction of the material inlet. A front inspection door 3 is connected between the front frame 4 and the rear frame 10. The front inspection door 3. A front liner 14 is provided on the inner side. The front inspection door 3 is symmetrically hinged on both side frames of the rear frame. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com