Horizontal spiral unloading sedimentation centrifuge of squeezing baffle plate structure

A settling centrifuge and horizontal screw technology, applied in the field of centrifuges, can solve the problems of breaking the centrifuge motor balance, increasing the vibration of the centrifuge, smelling and deteriorating, etc., to prolong the cleaning cycle, reduce dead angles, and enhance rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

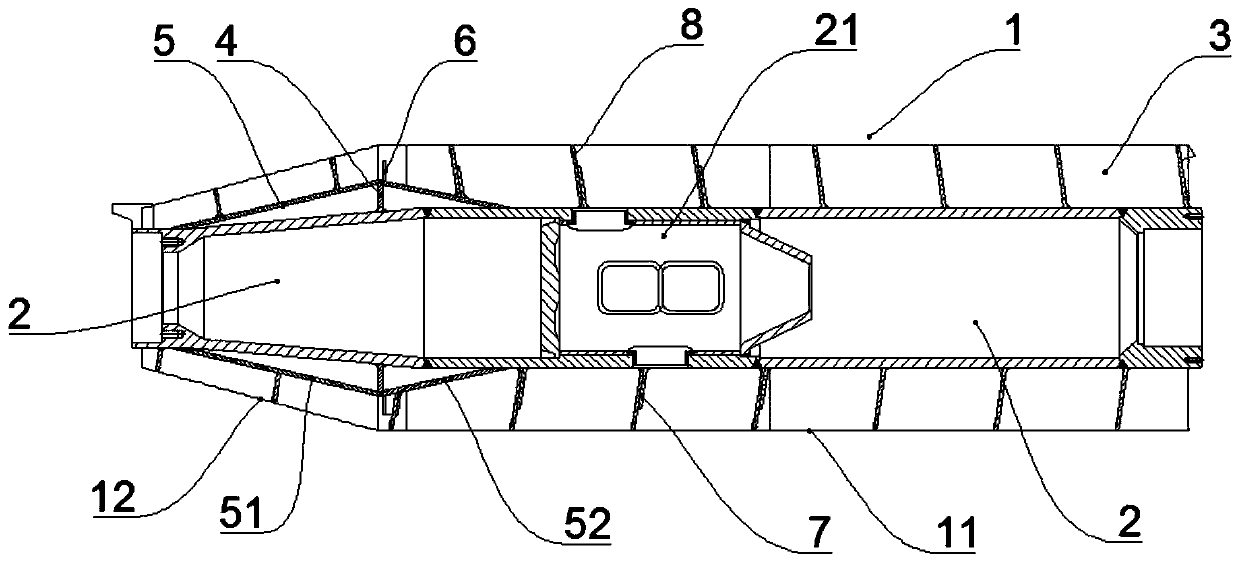

[0014] like figure 1 As shown, a horizontal screw discharge decanter centrifuge with a pressing baffle structure includes a barrel 1, a screw spindle 2 is arranged inside the barrel 1, the barrel 1 is composed of a straight cylinder 11 and a conical cylinder 12, and the screw spindle 2 It is composed of a straight section shaft 21 and a tapered section shaft 22. The junction of the straight section shaft 21 and the tapered section shaft 22 is set in the straight cylinder 11, and the connecting ring plate 4 is welded on the tapered section shaft 22, and the connecting ring plate 4 is located on the On the inner side of the joint between the straight cylinder 11 and the conical cylinder, the connecting ring plate 4 is connected with a figure-eight casing 5. The figure-eight casing 5 is composed of a first tapered casing 51 and a second tapered casing 52. The first tapered casing One end of 51 is welded to the connecting ring plate 4 , the other end is welded to the cone shaft 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com