Automatic following and quantitative ammunition loading robot

An automatic follow-up and robot technology, applied to ammunition, manipulators, weapon accessories, etc., can solve the problems of six-degree-of-freedom robots with limited carrying capacity, unstable charge quality, and limited use occasions, and achieve easy follow-up control and large movement space , the effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

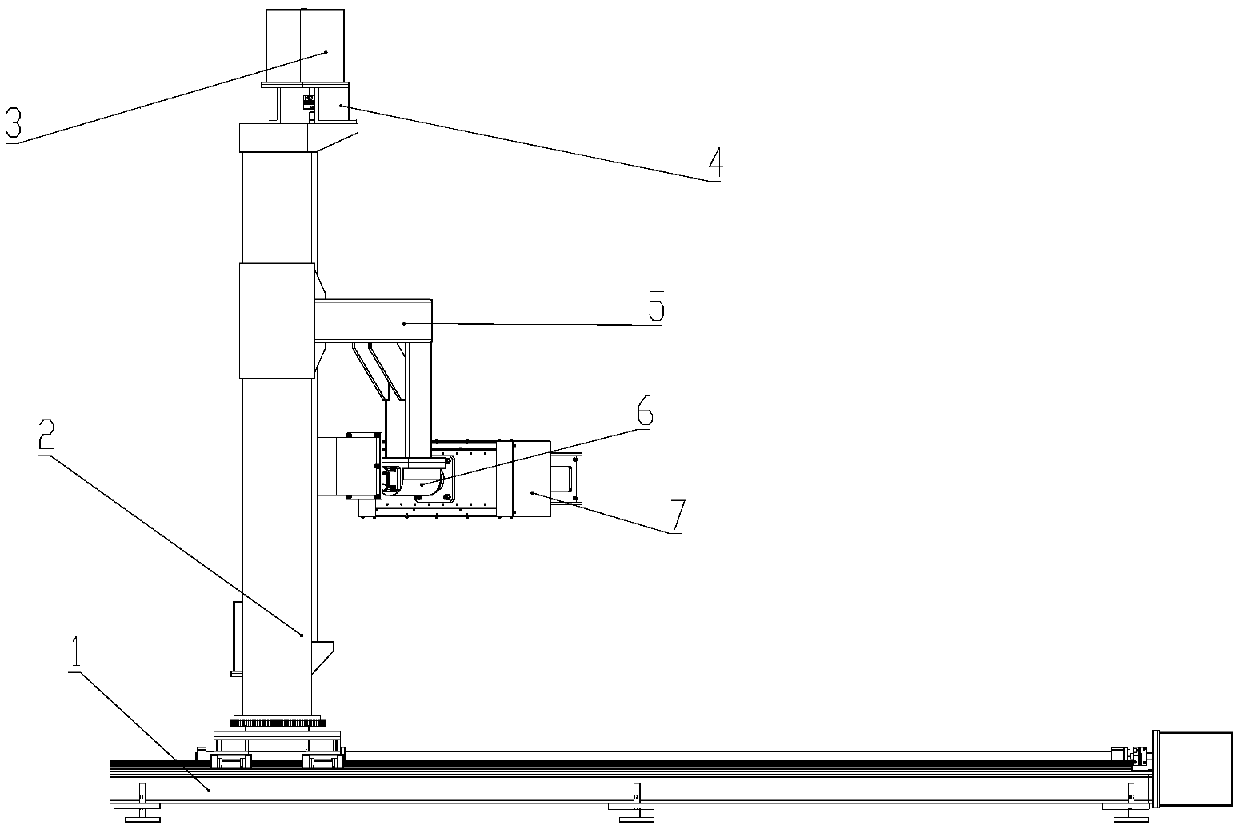

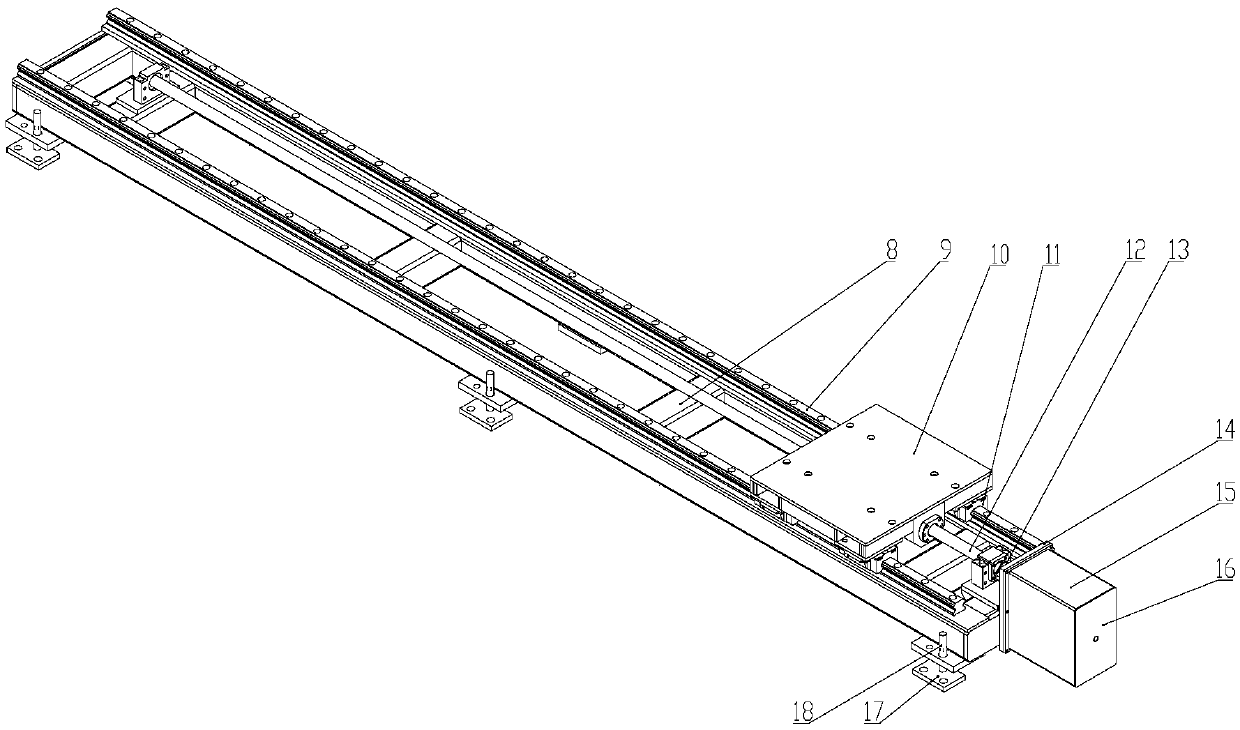

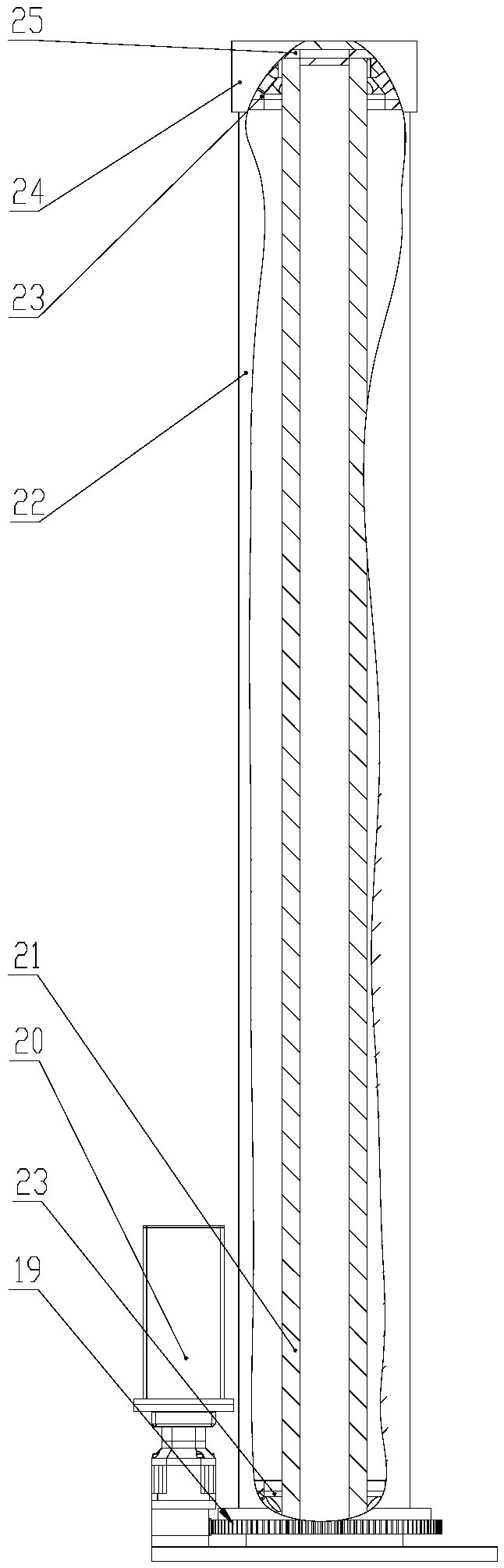

[0033] Such as figure 1 As shown, an automatic following quantitative charging robot provided by the present invention includes a horizontal movement unit 1, a rotary movement unit 2, a Z-direction drive unit 3, a lifting drive support plate 4, a swinging beam 5, an overturning movement unit 6 and a gripper Unit 7, wherein the rotary motion unit 2 is installed on the horizontal mobile unit 1, the swing beam 5 is slidingly connected with the rotary motion unit 2, the lifting drive support plate 4 is installed on the rotary motion unit 2, and the Z-direction drive unit 3 is connected with the lift drive support plate 4 is connected with the rotary motion unit 2 and connected with the swing beam 5 for driving the swing beam 5 up and down.

[0034] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com