Preparation method of comfortable copying pen holder

A pen holder and comfortable technology, applied in the direction of coating, etc., can solve the problems of easy fatigue damage of the pen holder, inconvenient copying, etc., and achieve the effects of not being easy to process, convenient for injection molding, and improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

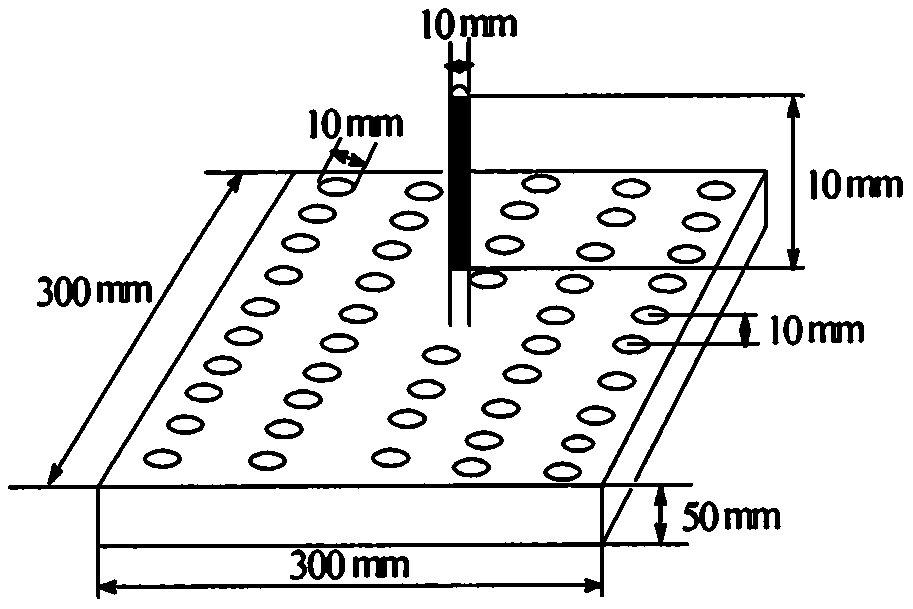

Image

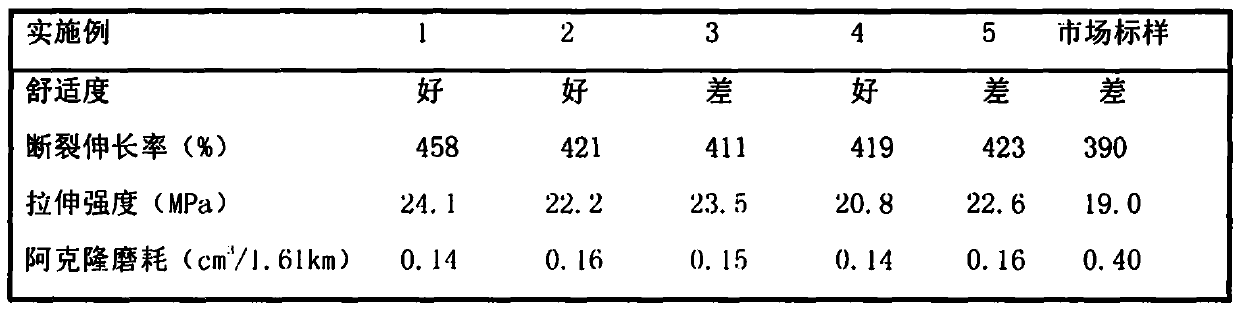

Examples

Embodiment 1

[0019] Mix EPDM rubber and 43 parts of compounding ingredients evenly, then dry the high-density polyethylene, add it to the extruder, and granulate it through the granulator. Finally, the two components are added to the barrel of the two-component double-channel injection machine. The rubber channel is 0.4 meters long and the temperature is 70 ° C. The plastic channel is 0.5 meters long and the temperature is 160 ° C. Inject into the cavity of a zigzag occlusal mold at a temperature of 150° C., and take out the molded product after the mold is closed for 8 minutes.

Embodiment 2

[0022] The difference between this embodiment and Example 1 is that in Embodiment 2, the length of the rubber flow path is 0.6 meters, the temperature is 100 ° C, the length of the plastic flow path is 0.5 meters, the temperature is 160 ° C, and the temperature is 150 ° C through injection at a 45° angle. °C mold, the mold was closed for 8 minutes.

Embodiment 3

[0024] The difference between this embodiment and Examples 1-2 is that in Embodiment 3, the length of the rubber flow path is 0.4 meters, the temperature is 70°C, the length of the plastic flow path is 0.3 meters, the temperature is 100°C, and it is injected through a 45° angle head to the temperature For 150 °C mold, mold closed for 8 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com