Automatic production line of PPTC over-current protection element

A technology for automated production lines and overcurrent protection components, applied in household components, applications, coatings, etc., can solve the problems of low safety, poor assembly accuracy, low efficiency, etc., and achieve the effect of compact coordination and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

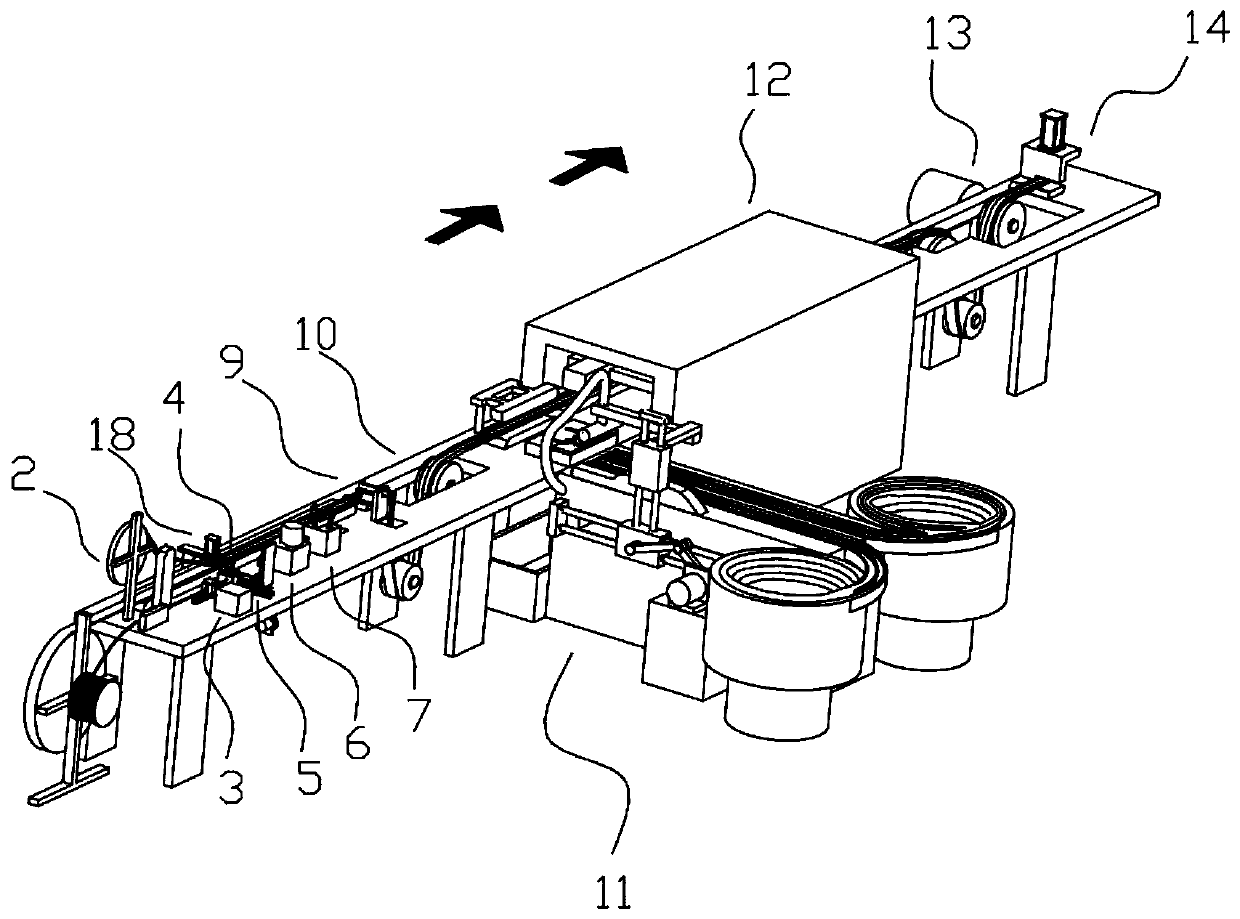

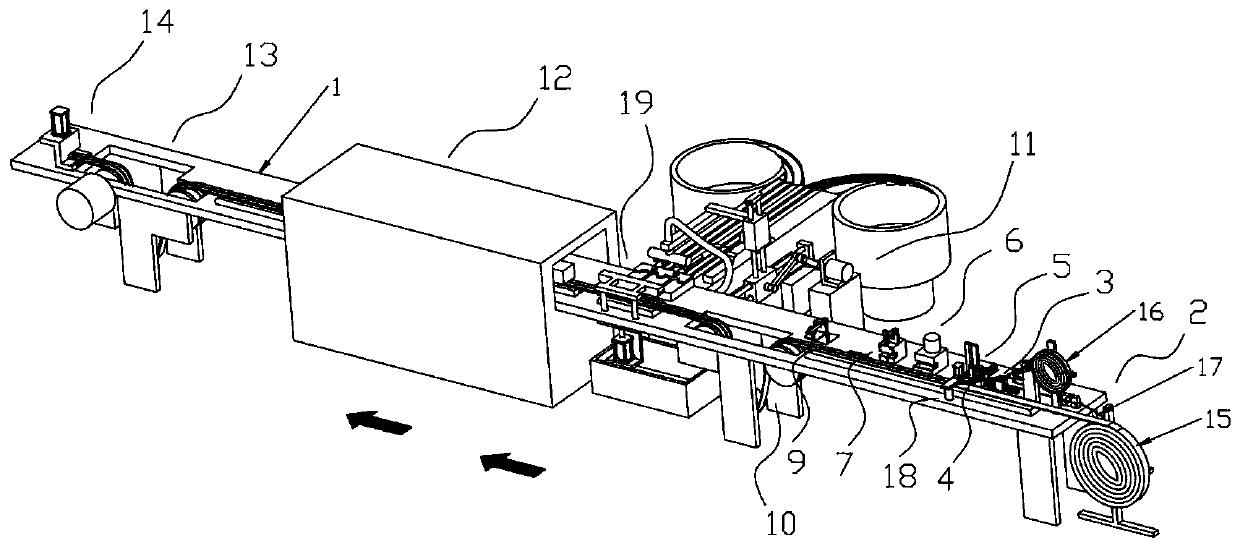

[0061] Such as Figure 1 to Figure 21 Shown, a kind of automatic production line of PPTC overcurrent protection element, comprise workbench 1, it is characterized in that, on the described workbench 1 in feeding direction, be installed with:

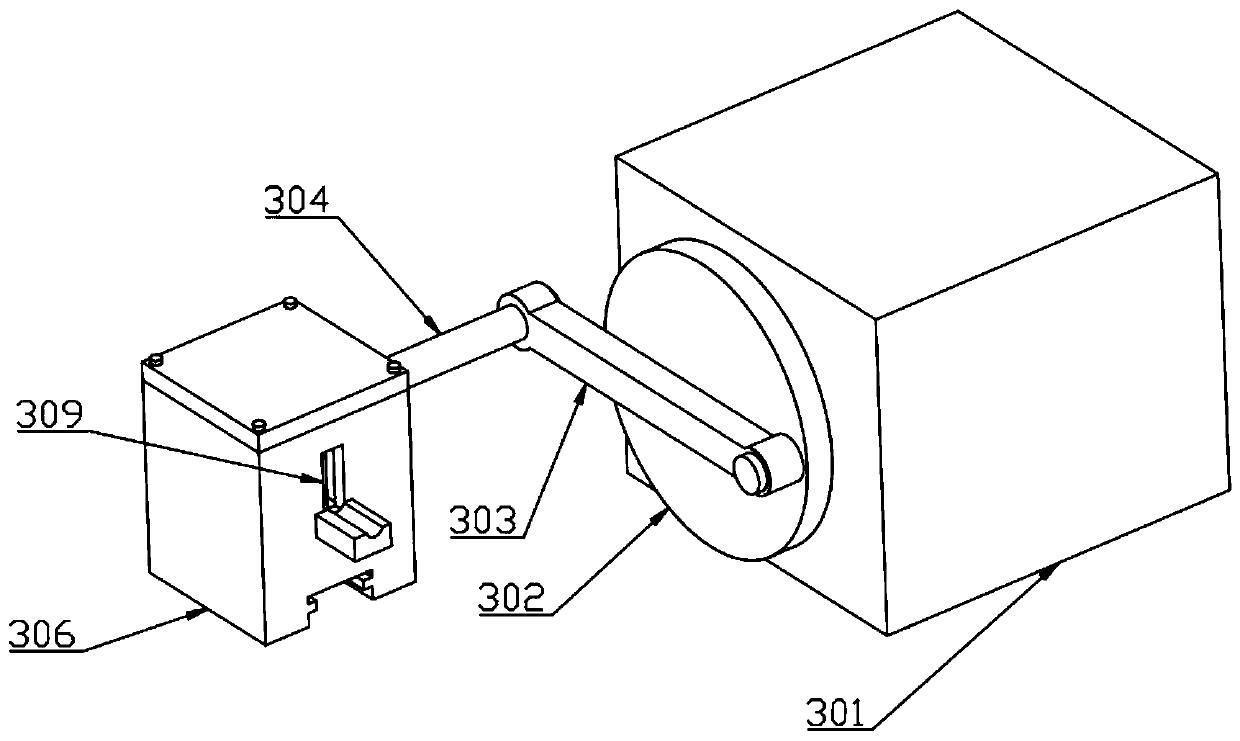

[0062] Feeding mechanism one 2, described feeding mechanism one 2 is used for feeding base tape 15, adhesive tape 16 and metal wire;

[0063] A feeding mechanism 3, the feeding mechanism 3 is used for stepping and feeding the metal wire;

[0064] A cutting mechanism 4, which is used for cutting the metal wire;

[0065] Bending mechanism one 5, said bending mechanism one 5 is used to carry out the first bending of "U" shape to the cut wire;

[0066] A tin coating mechanism 6, which is used to tin coat a pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap