Injection molding ABS gear ring with winding spiral induction teeth and production method thereof

A technology of ABS ring gear and production method, which is applied in applications, gears, household appliances, etc., can solve the problems of low product precision, many production processes, and low production efficiency, so as to reduce manufacturing costs, lighten the overall weight, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: An ABS ring gear with induction teeth located on the side wall of the ABS ring gear.

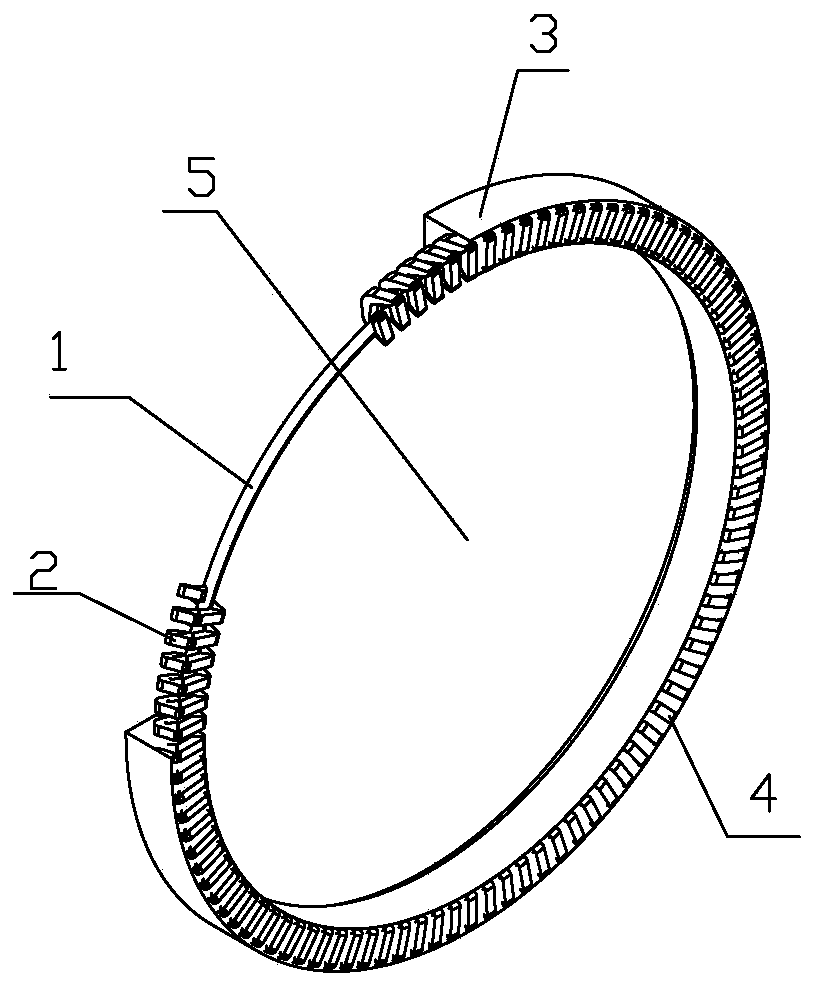

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Make the invention.

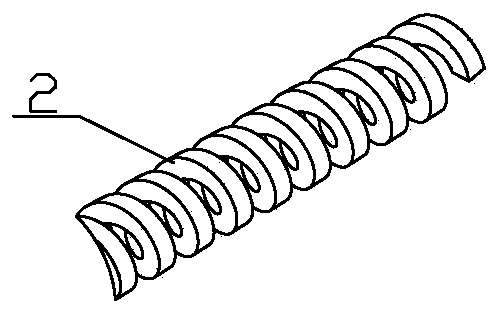

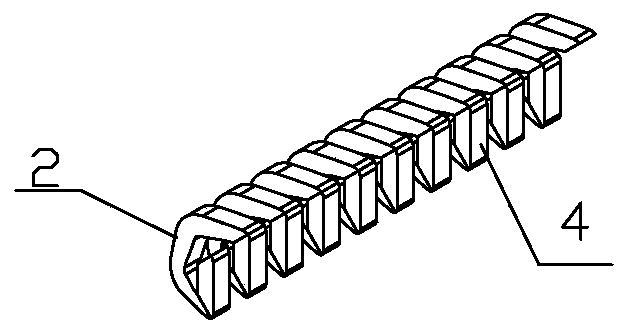

[0040] The injection-molded ABS ring gear with winding spiral induction teeth includes a filling ring seat 3, which is injection-molded into a ring shape, and the middle part is an inner hole 5, so as to facilitate the assembly of the ABS ring gear. It is characterized in that: Said filling ring seat 3 is embedded with a ring-shaped winding spiral body 2, said winding spiral body 2 is made of a soft magnetic material wire with a rectangular cross section, and the center of said circular winding spiral body 2 Coincident with the center of the filling ring seat 3, the winding spiral body 2 is provided with induction teeth 4 pressed into a plane and distributed equidistantly.

[0041] The induction teeth 4 are located on the same side of the ABS ring gear.

[0042] The coile...

Embodiment 2

[0056] Embodiment 2: An ABS ring gear with induction teeth located on the outer circle of the ABS ring gear.

[0057] refer to figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 Make the invention.

[0058] The injection-molded ABS ring gear with winding spiral induction teeth includes a filling ring seat 3, which is injection-molded into a ring shape, and the middle part is an inner hole 5, so as to facilitate the assembly of the ABS ring gear. It is characterized in that: Said filling ring seat 3 is embedded with a ring-shaped winding spiral body 2, said winding spiral body 2 is made of a soft magnetic material wire with a rectangular cross section, and the center of said circular winding spiral body 2 Coincident with the center of the filling ring seat 3, the winding spiral body 2 is provided with induction teeth 4 pressed into a plane and distributed equidistantly.

[0059] The induction teeth 4 are located on the outer circle of the ABS ring gear.

[0060] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com