Bidirectional push-pull trolley for pusher furnace

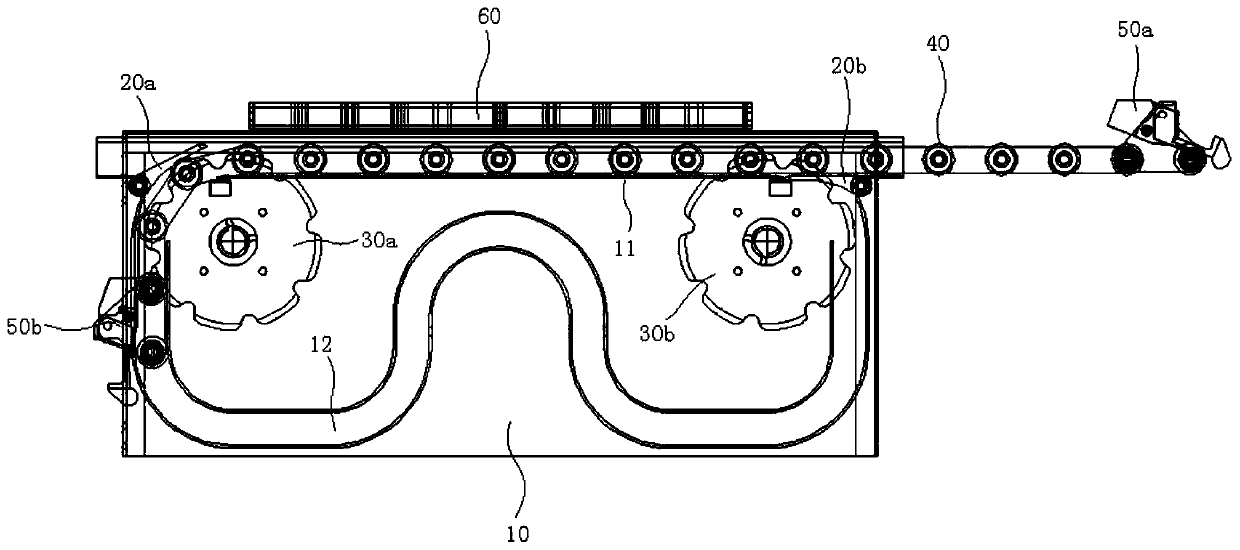

A technology of push-pull carts and push rod furnaces, which is applied in the field of two-way push-pull carts for push rod furnaces. It can solve problems such as collisions and failure of two-way push-pull carts to operate normally, and achieve the effects of reducing failure rates and improving equipment reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

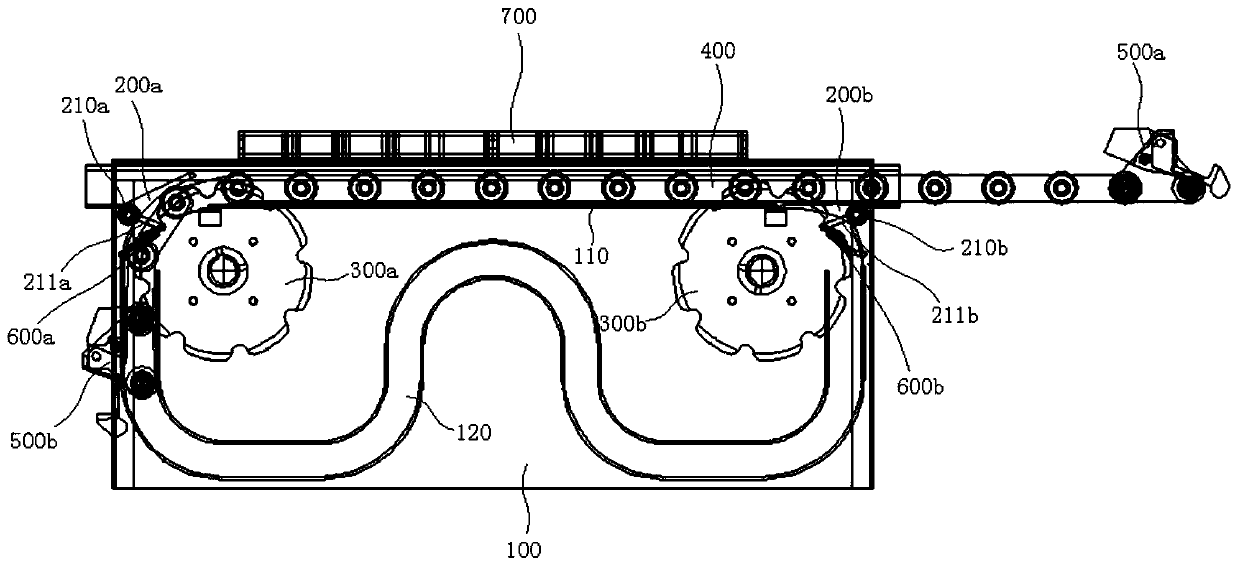

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0023] see figure 2 , shown in the figure is a two-way push-pull cart for a push rod furnace of the present invention, which includes a frame 100, a left one-way handle 200a, a right one-way handle 200b, a left push sprocket 300a, a right push sprocket 300b, the push-pull chain 400, the left push-pull hook 500a and the right push-pull hook 500b.

[0024] The top of frame 100 is provided with a walking bridge 110 along the horizontal direction, and frame 100 is positioned at the below of walking bridge 110 and is provided with a push-pull chain track 120, and the two ends of push-pull chain track 120 correspond to the two ends of walking bridge 110 and form a push-pull chain. Zipper loop walking loop.

[0025] The left and right side one-way h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com